Nickel Chemical Etching

Semiconductors are a class of electronic materials with properties between conductors and insulators. Metal nickel etching is a common semiconductor component processing technology, used to make micro devices and integrated circuits.

The principle of semiconductor metal nickel etching is to use the radiation of metal nickel to the semiconductor surface to achieve etching. In this process, the oxide on the surface of the semiconductor is removed, and the metal nickel is etched through a redox reaction to form the desired pattern and structure.

What Is Nickel Etching

This technique has many advantages, including high precision, scalability and repeatability. By adjusting the formula and temperature of the etching solution, the etching rate and precision can be controlled, making it suitable for different materials and structures. In addition, metal nickel etching can also produce high-quality microstructures without damaging the substrate, making it widely used in fields such as micro-nano processing and MEMS devices.

However, there are also some limitations and challenges in the etching of semiconductor metal nickel. First, effective ventilation and gas handling is required due to the large amount of gas generated during the etching process. At the same time, corrosive liquids and wastes are generated during the etching process, which need to be disposed of safely. In addition, there are still some defects in metal nickel etching, such as surface roughness, sidewall quality and etching residue, etc., which need to be solved by optimizing etching conditions and techniques.

In conclusion, semiconductor metal nickel etching is an important semiconductor processing technology. It can manufacture various micro devices and integrated circuits, and promote the development of micro-nano processing and MEMS applications. At the same time, it also poses some challenges and limitations that require continuous improvement and optimization.

Nickel Etching Service – Nickel Chemical Etching Company

Nickel is highly resistant to heat and corrosion, although it is relatively simple to etch with standard etch chemistries. Nickel Silver is the most cost-effective choice for electronic shielding because it can be soldered, won’t oxidize, doesn’t require additional plating/digital photo tools to offset expensive pressure tools, and can be added to bends so it can be handmade Out emi/rfi shielding parts. Its properties make it difficult to machine and, in fact, difficult to etch.

BE-CU customizes nickel etching service for customers. Customers only need to provide product design drawings and 3D drawings, and they can receive perfect nickel etched products without waiting too long.BE-CU completes the etching in the shortest time, is the cheapest and highest quality manufacturing technology, and guarantees excellent quality delivery.If you want expert support from a vendor you can trust, look no further than the precision etching services offered by Be-cu.com for your next nickel project.

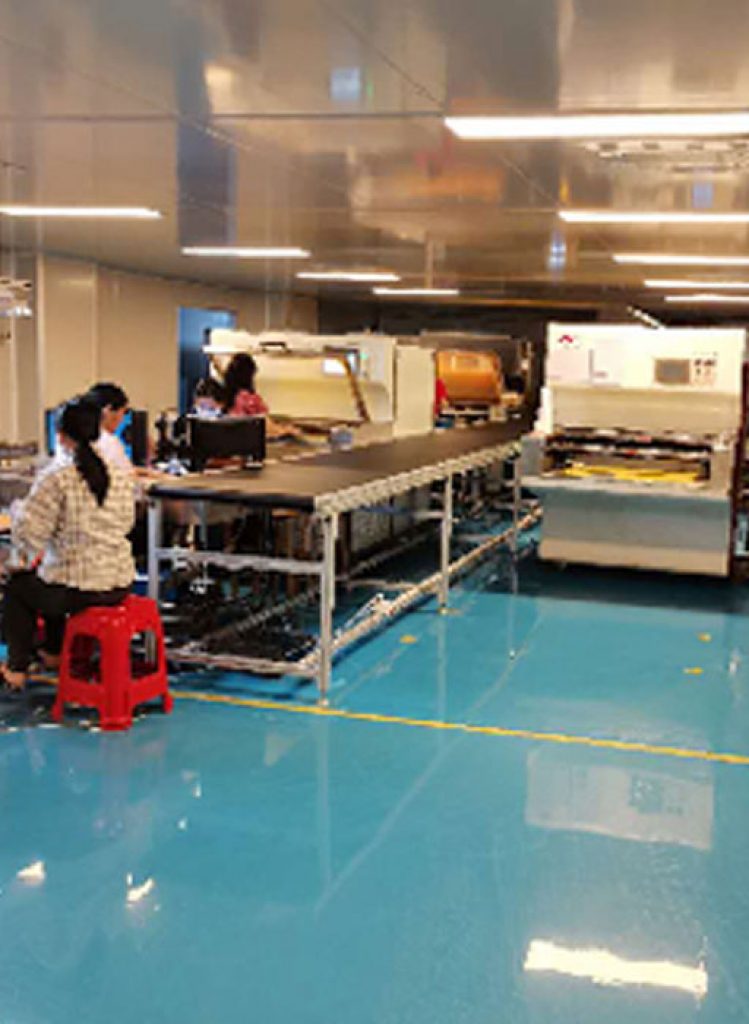

- Be-cu Prototype with 16 total automatic etching lines (10 horizontal and 6 vertical etching lines) which can deal with massive demand that request 700K piece per day as well as your individual customized small size requesting proceed by half automatic etching line.

- We have ful set of automatic production lines for cleaning, coating, development, etching and stripping etc with strong.

- Smallest line width 0.015mm, aperture 0.03mm with smallest tolerance as t 0.01mm can be fulfilled to meet your requirements

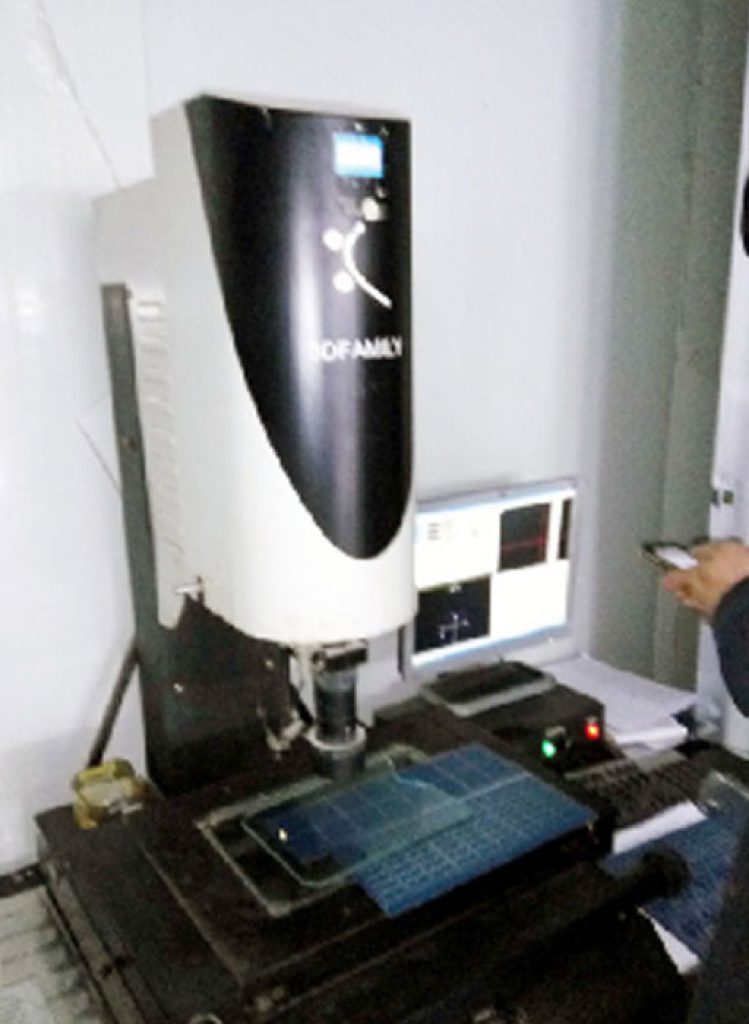

- Be-cu uses state-of-the-art digital imaging machines to precisely map designs onto the metal sheets and eliminate variations so production remains consistent – as do we.

With an ISO 9001:2015 certificated manufacturing factory, we provide material and full dimensional inspection reports as your request. You can always rest assured the parts you get from Be-cu.com will exceed your expectations.To use our online metal etching service, submit your design file for metal etching services and get instant metal etching quotes.

Nickel Chemical Etching Process In BE-CU Prototype

Automatic Shearing

Etching Metal

Coating For Etching Parts

Deinking

Automatic Baking Line

Automated Coating

Inspection For Etching

Exposure

Nickel Chemical Etching Parts & Case Studies In China

As one of professional Nickel Chemical Etching manufacturers from China, Be-Cu.Com has own specialized technical staff and management team to design as your custom draws and samples, we have rich experience and understand each type of the Nickel material characteristics. So we can offer you the best etching Nickel solution according to your requirements of Nickel parts and products.

-

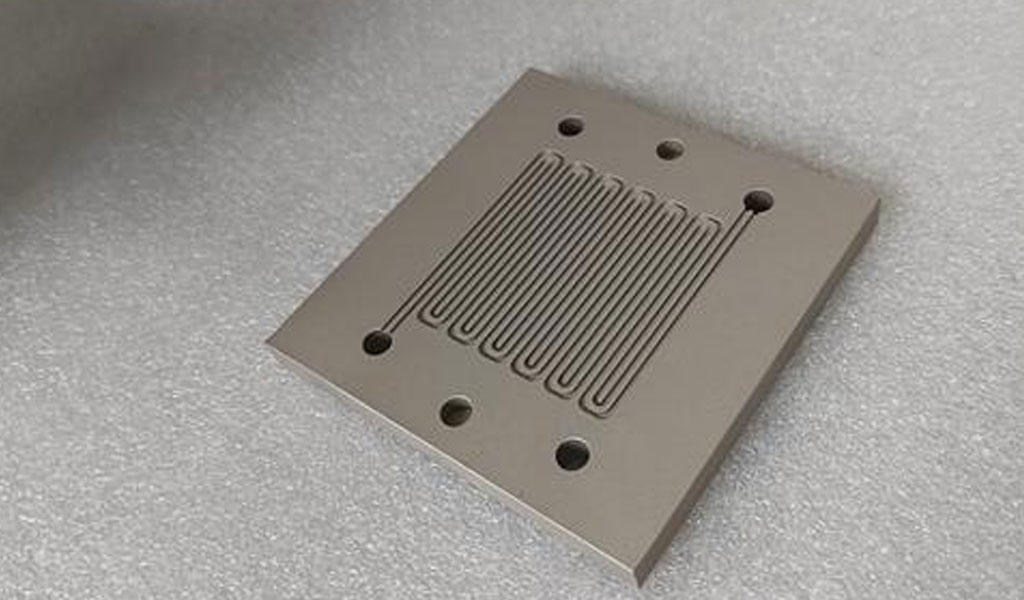

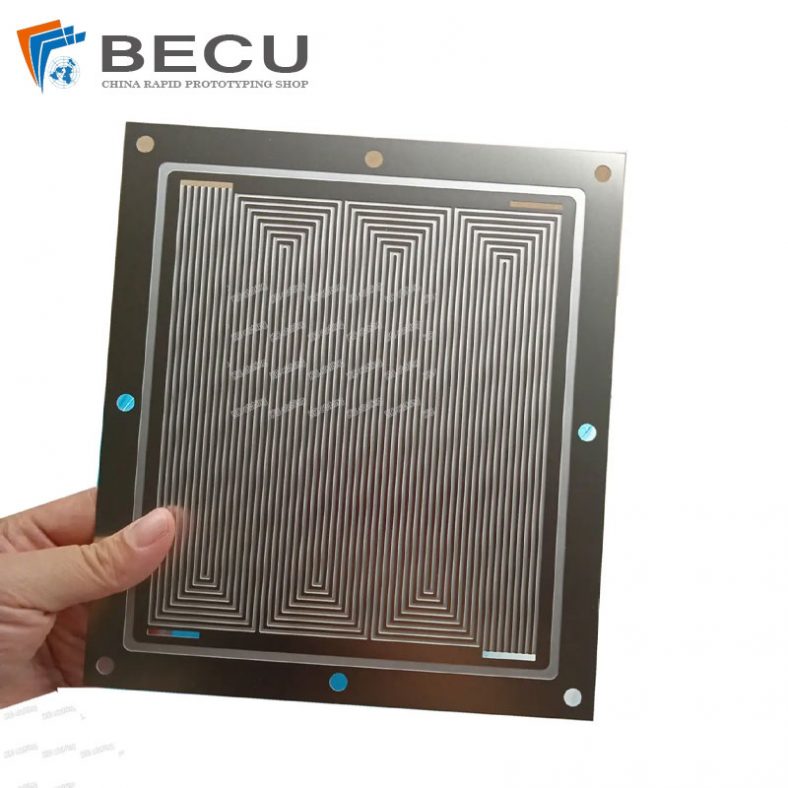

Metal Etched Hydrogen Fuel Cell Metal Bipolar Plates

-

Precise Etching Stainless Steel 316 High-Speed Hair Dryer Networks

-

Chemical Etching Stainless Steel 316 Bipolar Flow Plates

-

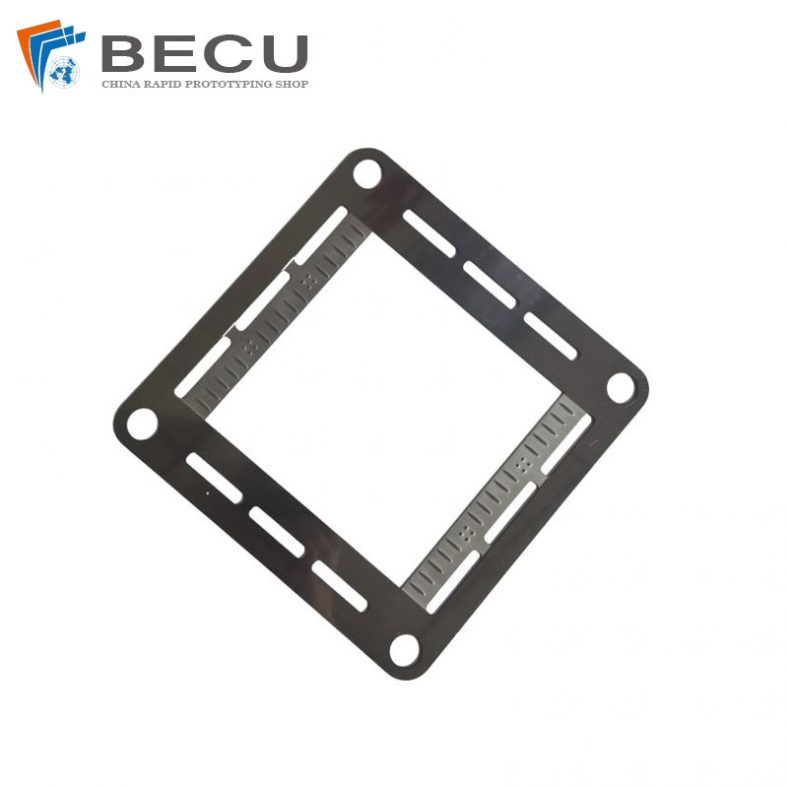

Laser Cut And Etching 303 Jewelry Pendant

-

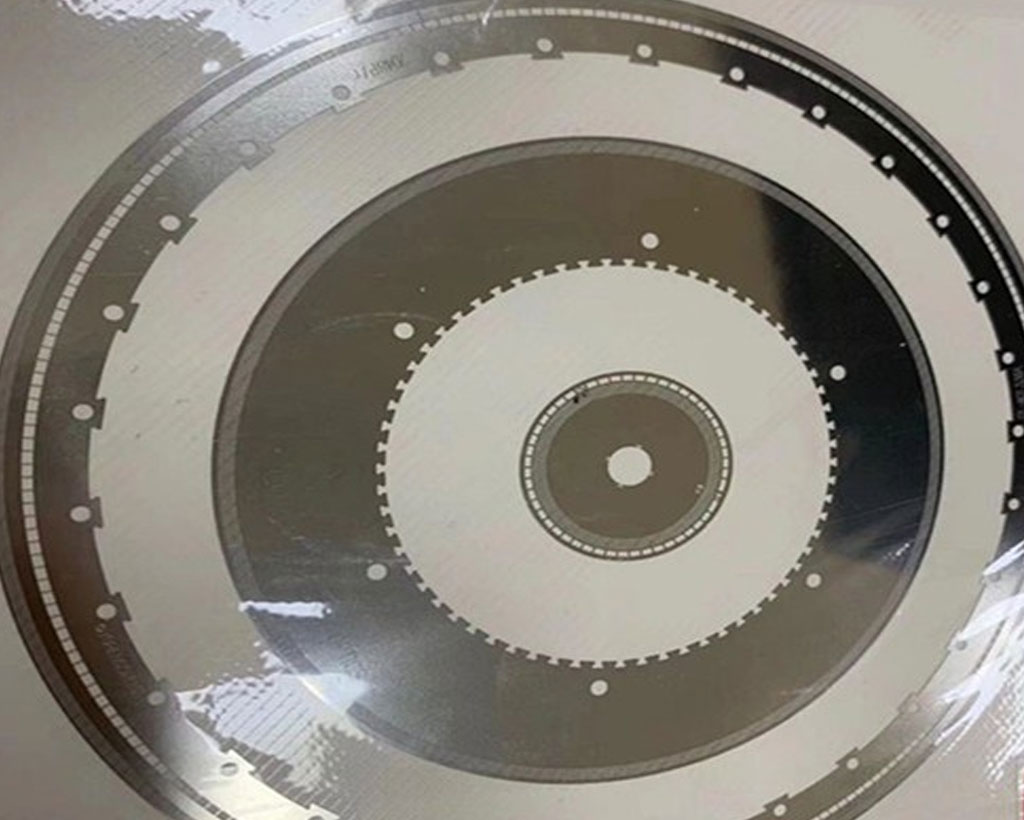

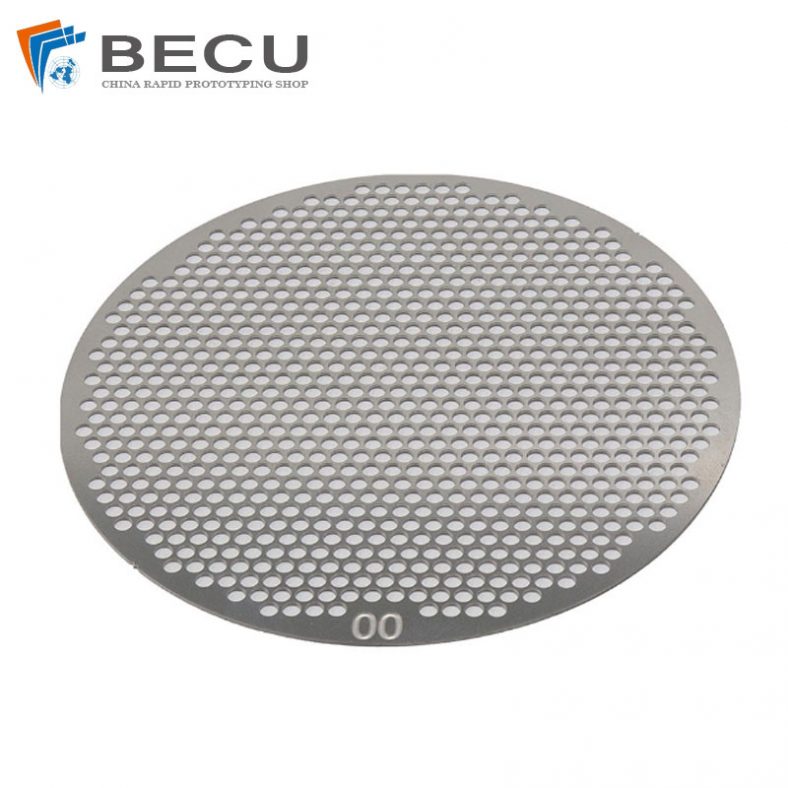

Photo Chemical Etching Microporous Dust Filter For Automotive Speaker

-

Precision Etching Automotive Audio Grille

-

Metal Etching 5 Inch Round Car Horn Protection Net

Surface Finishing Options for Nickel Chemical Etching

Parts made using photo etching usually feature excellent finishes. At Be-cu.com, we offer various custom finishing options that boost the produced part’s functionality, appearance, and durability.

- BLACKENING SERVICES

- ELECTROPOLISHING

- PAINTING

- PASSIVATING

- REAMING

- TUMBLING

- CUSTOM PACKAGING

Online Cooperate With Nickel Etching Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision etching and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.