Galvanized Steel Sheet Metal Fabrication

At the heart of sheet metal fabrication, we find galvanized steel – a material that has become indispensable in a multitude of industries.

But what is galvanized steel, and why is it so important? Galvanized steel sheet metal fabrication is a transformative process that finds its place in an array of industries, contributing to the creation of vital structures and products we encounter every day.

Galvanized steel is essentially steel that has undergone a unique metallurgical process known as galvanization.This Galvanized Steel Sheet Metal Fabrication process involves applying a protective zinc coating to the steel’s surface, which, in turn, offers an exceptional combination of strength, corrosion resistance, and versatility.The significance of galvanized steel sheet metal fabrication lies in its wide-ranging utility, making it the material of choice for an extensive list of applications across various industries. The galvanization process enhances the steel’s longevity and durability, ensuring that structures and products made from it can withstand the test of time and the most challenging environmental conditions.

There are dozens of Galvanized Steel sheet metal fabrication techniques available. For example, butting flat sheets, bending parts, drilling holes, adding slots, notching, etc. These techniques enable us to make complicated Galvanized Steel parts.

Materials Suitable for Galvanized Sheet Metal Fabrication

Galvanized steel sheet metal fabrication comes in various types and forms to suit different applications and requirements. The choice of galvanized steel sheet metal type depends on factors such as the intended use, environmental conditions, and fabrication processes. Here are some common types of galvanized steel sheet metal:

Hot-Dip Galvanized Steel (HDG)

It is created by immersing steel sheets in a bath of molten zinc, which forms a thick, protective zinc coating on the steel’s surface.

HDG offers excellent corrosion resistance and is suitable for outdoor and high-moisture applications.

Electrogalvanized Steel (EG)

EG is known for its smooth and consistent coating, making it suitable for applications where aesthetics or surface finish is critical.

Galvannealed Steel

This process forms a zinc-iron alloy coating that offers not only corrosion resistance but also improved paint adhesion, making it ideal for applications where painting is necessary.

Galfan® Steel

It offers enhanced corrosion resistance, particularly in marine and highly corrosive environments, making it an attractive option for such applications.

Continuous Galvanized Sheet (CGS)

This process forms a zinc-iron alloy coating that offers not only corrosion resistance but also improved paint adhesion, making it ideal for applications where painting is necessary.

Zinc-Aluminum Coated Steel

It provides improved corrosion resistance compared to traditional galvanized steel and is often used in roofing and cladding applications.

Corrugated Galvanized Steel

They are commonly used in roofing, siding, and agricultural applications.

Embossed or Textured Galvanized Steel

Perforated Galvanized Steel

Painted or Powder-Coated Galvanized Steel

Pre-Painted Galvanized Steel (PPGI)

Heavy Galvanized Steel

The choice of galvanized steel sheet metal type is influenced by the project’s specific requirements, including factors such as corrosion resistance, aesthetics, structural integrity, and cost-effectiveness. Different industries and applications may prefer one type over another based on these considerations.

Custom Galvanized Steel Sheet Metal Fabrication Service In China

Be-Cu prototype provides active custom Galvanized Steel Sheet Metal Fabrication design support services according to the custom sheet metal’s application scenarios, functional requirements, and stringent acceptance criteria to ensure that products meet customer product expectations.

As a company, we offer a range of galvanized steel sheet metal fabrication solutions depending on client’s requirements and designs. Whether you want Be-Cu prototype to:

- Cut galvanized sheet metal

- Bend galvanized sheet metal

- Weld galvanized sheet metal

- Punch, stamp or engrave galvanized sheet metal or

- Apply additional surface finish

Be-Cu prototype has an experienced team of design experts who will create various product design and manufacturing solutions through CAD/Solidworks, and aesthetic designs for various application scenarios. You can easily choose the most ideal result.

Why Use Our Galvanized Steel Sheet Metal Fabrication Services

Be-cu.com is one of the reliable precision sheet metal galvanized steel parts manufacturer in the China. Our years professional sheet metal equipment provide you all-around care services that our experienced project engineers and machinists will analyze your project carefully and process it with the most efficient process of sheet metal fabrication galvanized steel to to meet your design specification, while optimize your time and cost.The Top 6 Reasons:

- No MOQ:One-off Galvanized steel laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom Galvanized steel laser cutting process and technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter and other galvanized steel sheet metal fabrication equipment at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the automotive,medical and electronic industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

- Wide range of coatings & finishes:We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

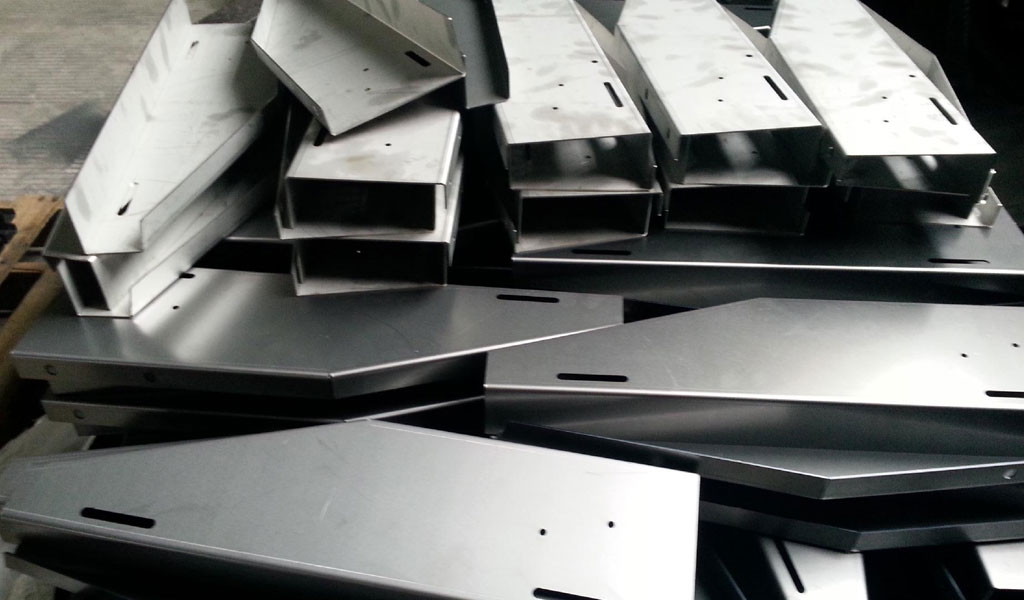

Our Capabilities And Case Studies Gallery Of Galvanized Steel Sheet Metal Fabrication

At Be-cu.com, we are highly experienced in manufacturing custom steel sheet metal parts for demanding applications. By providing a cost-effective fabrication service that doesn’t sacrifice precision or quality, we benefit our customers by making their design ideas for crucial parts and project components become a reality.For more case studies about our services, see the products list below and contact us directly.

-

Custom Sheet Metal Surgical Instrument Sterilization Box For Beauty Salon

-

Precision Fabrication Green Energy EV Charging Station Cabinet

-

Outdoor Rainproof Weak Current Communication Network Sheet Metal Cabinet

-

Sheet Metal Fabrication Distribution Electric Cabinet

-

Metal Fabrication Cold Rolled Sheet Medical Device Enclosure

-

12.1 Inch Vertical Inquiry Kiosks

-

65-Inch Vertical Touch All-in-one Advertising Machine Sheet Metal Shell

-

LCD Display Advertising Machine Sheet Metal Frame

-

Custom 32 Inch Ordering Machine Kiosk Chassis

-

SPCC Sheet Metal Fabrication Financial Device Enclosure