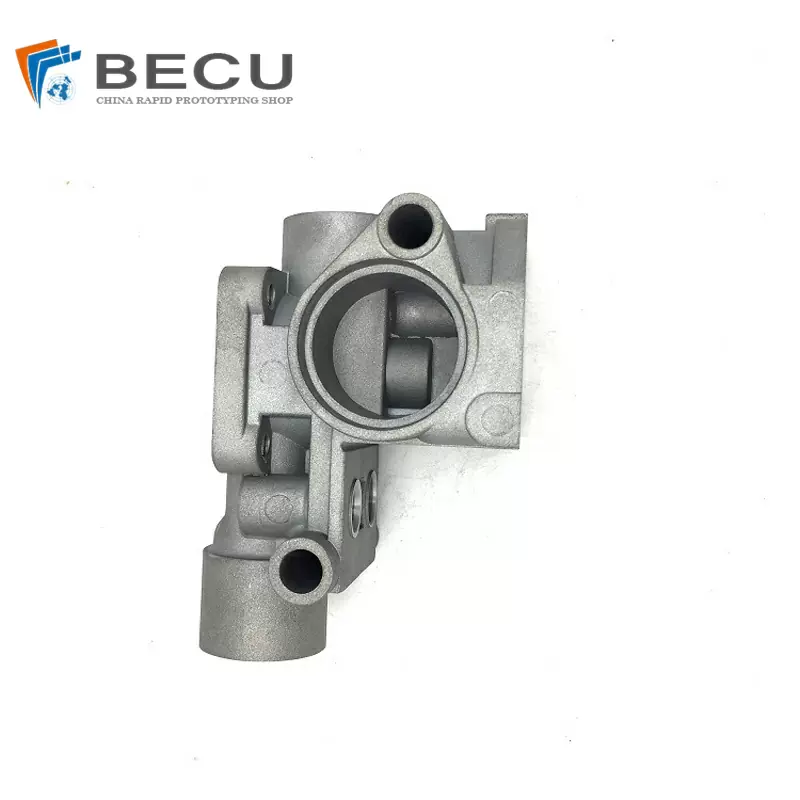

Automotive Brake Aluminum Alloy Parts

- Material: Aluminum Alloy

- Casting Process:HPDC/Magnesium Die Casting

- Die Casting Machine: 400~1650T

- Weight:1.0~10.0kg

- Dimension: According To Customer’s Drawings

- Annual Volume: 100,000 per year

- Porosity requirements: ASTM E505 Level 3

- Leakage test requirement:Custom

- Surface treatment:Custom

- Application: Automotive

High-Quality Open Die Casting Of Automotive Brake Aluminum Alloy Parts

Open-die die-casting manufacturer of aluminum alloy parts for automotive brakes. Available molds include stamping molds, micro zinc die casting molds, four-slide casting molds, and plastic injection molds. Capabilities include punching capacities from 24 to 150 tons. Steel and brass coils are available for orders with short lead times. Stamping dies can be built for external or internal production runs. Parts can be run in master molds with interchangeable cutting inserts. Die casting can produce parts up to 9 oz. Computer-controlled machines can be fine-tuned and castings can be trimmed on site. Vibration finishing polishes and removes sharp edges. Manufacture of custom machinery to process die castings and perform secondary operations including drilling, reaming, tapping, chamfering and deburring. Secondary operations include drilling, reaming, tapping, chamfering and deburring.

The Advantages Of Open Die Casting Of Automotive Brake Aluminum Alloy Parts

- – ISO Certification: We are an ITAF 16949 And ISO 9001:2015 certified China metal casting manufacturer that proficient in making service for aluminum die casting、zinc die casting、investment castiong 、sand casting and cnc machining.

- – Quality Control: We use a quality assurance checklist for all of our products to effectively track, examine, and verify whether the produced aluminum castings meet the necessary standards and requirements.

- – Broad Applications: Our precise metal casting parts and mouldings serve lots of critical industries and leading companies.

- – Plant and Facilities: We have a large die casting factory、investment casting line and sand casting line with die casting manufacturing machinery and up-to-date CMM measuring instruments.

- – OEM Capacity: If you need custom metal castings with specific configurations, our cnc machining service can realize your complex designs comfirm,Experienced designers and electronic engineers will assist you in completing the entire project. Not only your project parts, our ideas in creativity.

- – High Productivity: reliable raw material supplies and a team of trained staff enable metal casting parts to be manufactured with high efficiency within the promised period.

- – Low Cost: Our cost control on the process, our metal casting parts at lower prices than other metal castings manufacturers.This is the difference in strength

Specifications of Open Die Casting Of Automotive Brake Aluminum Alloy Parts

| Material | Aluminum、Zinc、Brass、Stainless Steel、Titanium etc |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom (Sand Blasting, Polishing, Spray painting, Pad Printing, Colour Electrophoresis, Mirror Finishing, Silk-Screen Printing, Oxidation) |

| Main Process | Die Casting(up to 3000 tons),Hot Chamber Die Casting, High Pressure Die Casting,Investment Casting,Sand Casting etc., |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Automotive |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Die Casting Company

If you are looking for dependable volume manufacturing metal parts supplier with High pressure die casting service who offers you competitive price, good service and quality for aluminium die casting, zinc, or magnesium die casting, then BE-CU Prototype are surely a partner you are looking for to fulfill all your die casting needs. With quality service and state of art technology, BE-CU indeed claim in providing quality pressure die casting including aluminum/zamak/magnesium alloy castings to our customers all over the world.

To work with us,be-cu don’t just stop at taking your order and delivering your die casting products. be-cu are there for you at every step right from your preferred selection of aluminum die casting, Zamak die casting (Zamak 2, Zamak 3, Zamak 5, Zamak 8) or magnesium die casting products and services to post-order phase. In brief, once you become our customer, be-cu are with you every step on the way.

-

CNC Machining Gas Stove Bottom Joint

-

Gravity Die Casting Custom Street Light Heat Sink

-

Die Casting LED Canopy Lights Heatsink For Gas Station

-

Zinc Die Casting PA10 Transformer Connector Terminal

-

Die Casting Aluminium Cookware Chassis

-

Die Casting Wheels With Aluminum Alloy 5 Axis CNC Machining

-

Precision Machined Copper Die Casting Parts

-

Professional Small Baler Aluminum Alloy Die-casting Mold Production

-

China Die Casting Factory Manufactures Surface Sprayed Aluminum Valve Body

-

Extrusion Die-casting Polyurethane-Coated Aluminum Alloy Profiles

-

Custom Precision Aluminum Die Cast Brackets and Finishes

-

Extrusion Die-casting Magnesium Alloy Heat Sink Shell