Exhaust Manifold

- Product name: Car Exhaust Pipe

- No+Color:Custom

- Surface treatment: Custom

- Product material: Inconel 3D Printing Material

- Application: Automotive 3D Printing

- Proofing cycle:7 days(100000 pcs/M)

- Machining Factory:BE-CU.com

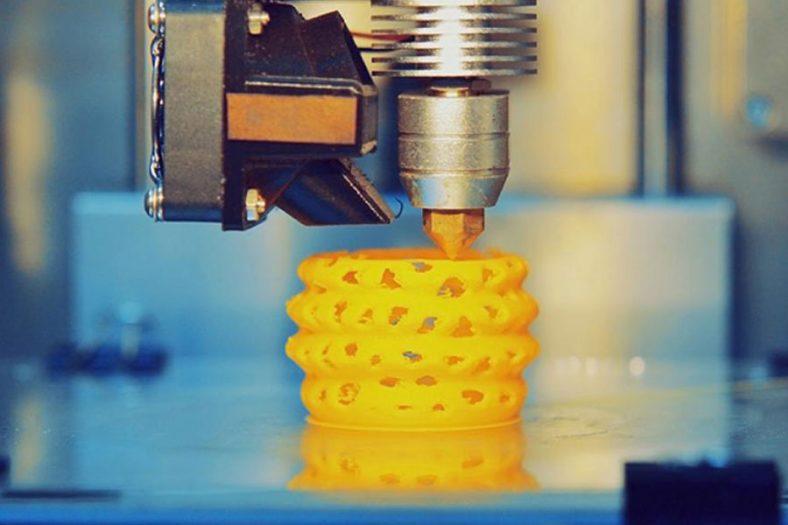

- Production Process: SLM 3D Printing

- Size:According To Customer Drawings

High-Quality 3D Printed Inconel Exhaust Manifold

An exhaust manifold is a crucial component of internal combustion engines, responsible for collecting exhaust gases from the engine’s cylinders and directing them into the exhaust system. The efficiency and design of the exhaust manifold are vital to the overall performance of the engine, affecting factors such as exhaust flow, fuel efficiency, and emissions. Traditionally, exhaust manifolds are manufactured using cast iron or stainless steel, but the advent of advanced materials and manufacturing techniques has opened up new possibilities.

Material selection for exhaust manifolds is critical due to the extreme conditions under which they operate. The manifold must withstand high temperatures, corrosive environments, and mechanical stresses while maintaining structural integrity and performance. Conventional materials such as cast iron and stainless steel have been widely used, but they present limitations in terms of weight, durability, and design flexibility.Inconel is a family of nickel-chromium-based superalloys known for their exceptional resistance to heat and corrosion. These alloys maintain their mechanical properties at high temperatures, making them ideal for applications in harsh environments such as aerospace, chemical processing, and power generation. Inconel alloys, particularly Inconel 625 and Inconel 718, have become popular in the production of exhaust manifolds due to their ability to withstand the extreme conditions found in internal combustion engines.

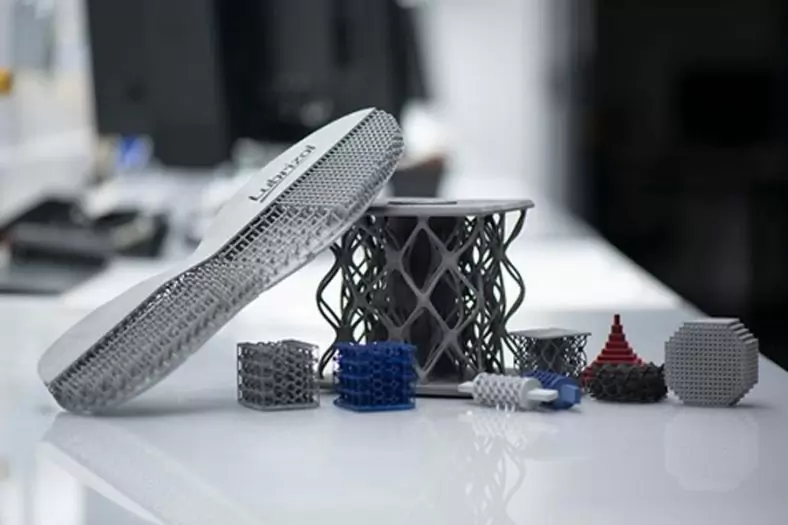

The combination of Inconel’s properties with the design freedom offered by 3D printing has the potential to revolutionize the manufacturing of exhaust manifolds, leading to improved performance, reduced weight, and enhanced durability.

In recent years, high-performance alloys like Inconel have gained attention for their superior properties, including excellent heat resistance, corrosion resistance, and mechanical strength. The use of Inconel in exhaust manifolds offers significant advantages, particularly in high-performance and high-temperature applications.

In the automotive development process, parts are often required to be obtained in the shortest possible time, and since the number of parts needed for testing is not large, 3D printing of automotive prototype parts has become an important option to reduce development costs. The design of an automotive intake manifold is quite complex, requiring the assembly and welding of multiple components during production to achieve the final part, whereas 3D printing allows for integrated formation.OUR 3D Printing Solutions for Automotive Intake Manifolds:

- Precision: Up to +/- 0.2mm, with a maximum length dimension of 680mm.

- Material: Printed using Inconel, which offers high strength, high toughness, and high-temperature resistance, fully meeting the functional design verification requirements.

- Integrated Production: All parts are produced and printed in one go, without splicing, ensuring part strength and completely surpassing traditional manufacturing methods.

Our 3D printing technology advantages include the ability to quickly correct design errors, improve production efficiency, and reduce development costs. Compared to traditional mold development, forging, casting, and other complex processes, it simplifies intermediate steps and shortens the development cycle. Compared to the current development cycle of more than 15 days for parts, 3D printing technology, depending on the complexity of the parts, only requires a development cycle of 2 to 7 days.

Why Choose 3D Printed Inconel Exhaust Manifold Service?

- – No minimum order quantity

- – Metal or plastic 3D printed prototype and production parts in 7-10 days

- – Precision custom 3D printing parts at affordable prices

- – Online free quote in the shortest time

- – Single prototypes or complex shapes are both allowed

- – A wide selection of metal or plastic materials

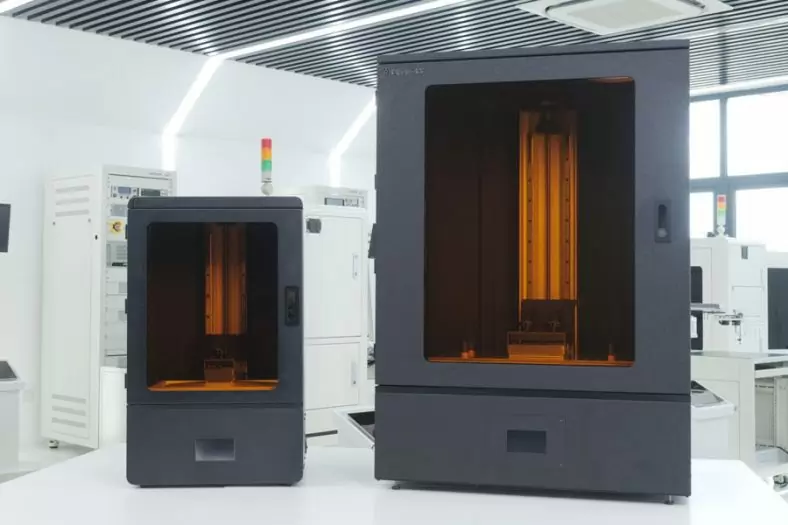

- – Commercial and industrial-grade 3D printers

- – Cooperative supplier assistance project

- – Provide a quick solution for small batches of complex prototypes

- – We provide with our partner

- – 3D printing services for metals and plastics

- – Meet the rapid needs of complex prototype designers

- – For SLA: 0.4mm wide and high

- – For SLS: 1mm wide and high

Be_Cu is your specialist when it comes to professional 3D-printing services in China. In a technical analysis we offer you the possibility of a 3D-print specific component analysis as well as a subsequent optimization of your 3D components.Right from the beginning, we work together with our customers to find suitable solutions to turn your ideas into real products. If required, we can also develop your product for 3D printing production at Be-Cu Prototype.Be-Cu has many years of experience in multicellular 3D printing processes. We are your partner for special 3D-printing processes in China, as we have a large in-house production and skillful engineers to realize your 3D-products.

Contact Be Cu Now for your Custom 3D Printing Fabrication, We are your best online 3d printing services choice!

The Specifications Of 3D Printed Inconel Exhaust Manifold

| Item Name | Inconel 3D Printing |

| Material | Austenitic Stainless Steel 316L, Martensitic Stainless Steel 15-5PH, Martensitic Stainless Steel 17-4PH |

| Thickness | Custom |

| High Precision | +-0.15mm |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Custom (Anodized, powder coating, etc.) |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Detail Of BE-CU 3D Printing Company

BE-CU.COM offers online 3D printing services for rapid prototyping and production in volume. Our clients are across a wide variety of industries and companies, including automotive, construction, aerospace, defense, electronics, machinery, industrial automation, medical, healthcare, consumer production, oil & gas, etc. Accelerate your product development and manufacturing process with our industry-leading metal & plastic 3D printing service and 3D printed parts. We’ll find the best 3D printing solution for your projects, to lower your cost and shorten the lead time based on your needs, while maintaining the quality. From 3D prototyping to end-use parts production, multiple materials are available for custom 3D printing parts. Need an alternative to the traditional solution? Submit your 3D CAD file to get an online quotation quickly. Our 3D printing service ensures accuracy and speed. We can help you choose the most appropriate technology and material to match your applications or request.

-

3D Printed Inconel Exhaust Manifold

-

3D Printed Black Myth: Wukong Model

-

Omni-Directional Surgical Planning Medical Models

-

3D Printing Pool Pressure Cleaner Parts and Accessories

-

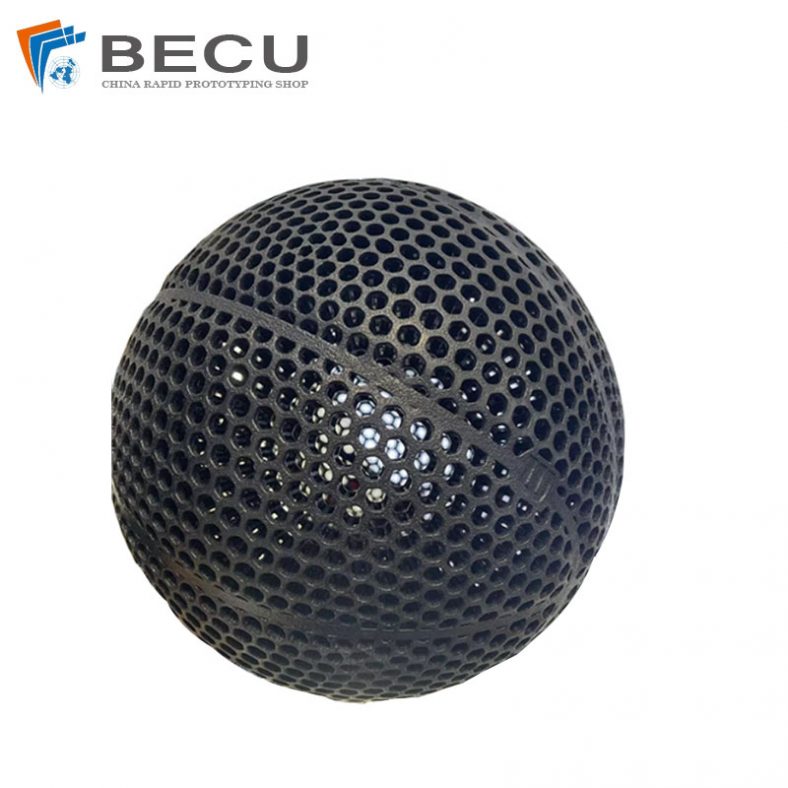

Nylon 3D Printed Size 5 Basketball

-

Black Nylon Medical Threaded Screw By MJF 3D Printing

-

MJF 3D Printing Black Nylon Red Dot Sighting For Medical

-

jetFusion 3D Printing Triceratops Mother and Child Sculpture