What Is Stainless Steel 3D Printing?

3D printing with stainless steel material involves using specialized 3D printing processes to create objects using stainless steel as the primary material. As a conventional material for 3D printing, stainless steel is usually used in direct metal laser sintering (DMLS) or selective laser melting (SLM printing) processes.Stainless steel is characterized by high mechanical strength and strong corrosion resistance. From early industrial manufacturing to the application of 3D printing technology, this metal material is widely used in the production of various industries. 3D printing stainless steel materials mainly include heat-treatable 17-4 PH stainless steel and extremely corrosion-resistant 316L stainless steel.

Are you looking for the perfect stainless steel 3D printing material for your project? Stainless Steel allows to produce corrosion-resistant and functional parts. Here are all materal information and advice to help you print your 3D model in our Stainless Steel material.

| Physical Property | DMLS/SLM Stainless Steel 316L | DMLS/SLM Stainless Steel 17-4 PH |

|---|---|---|

| Density | 7.98 g/cm³ | 7.7 g/cm³ |

| Melting Point | 1400-1450°C (2552-2642°F) | 1350-1380°C (2462-2516°F) |

| Thermal Conductivity | 15-16 W/m·K | 16-17 W/m·K |

| Electrical Conductivity | 2.4-3.2 MS/m | 17-20 MS/m |

| Magnetic Properties | Non-magnetic | Magnetic |

| Hardness (HRC) | 30-35 HRC | 36-42 HRC |

3D printing with stainless steel allows for the creation of complex, custom parts with the desirable properties of stainless steel. It offers design freedom, rapid prototyping, and customization possibilities in various industries, but it’s important to consider the specific requirements, constraints, and capabilities of the 3D printing process and materials when planning for stainless steel printing.

The Advantages Of DMLS 3D Printing Stainless Steel

- The advantage of Stainless Steel 3D printing is that the mechanical properties of stainless steel can be changed by changing the microstructure and internal force distribution.

- Research into Stainless Steel 3D printing has also demonstrated material savings compared to traditional methods.

- High-tech industries using metal 3d printing have demonstrated faster manufacturing of complex parts, higher material strength, and ductility advantages compared to traditional methods.

- Stainless Steel additive manufacturing also enables the production of highly optimized structures that would otherwise be expensive, time-consuming, or even impossible to manufacture using traditional manufacturing methods. Additionally, 3D printed stainless steel parts can be used with other parts to create hybrid structures.

- Using stainless steel 3D printing, it is also possible to fabricate structural parts with energy-absorbing properties and internal reinforcement properties. Furthermore, undesired residual stresses generated in structural applications can be converted into favorable prestressing stresses.

Significant challenges remain in stainless steel 3D printing for a variety of industrial applications. In some cases, 3D printing stainless steel is more expensive than traditional production methods. In metal 3D printing, existing design methods must be modified to accommodate changes in material properties and variable geometries.

Metal additive manufacturing technology needs to be more standardized, and new quality assurance procedures need to be implemented to ensure that manufactured parts are reliable over their life cycle. As long as these technical and industrial challenges are addressed, stainless steel 3d printing has great potential for applications in various industries.

3D Printing Stainless Steel Parts – Stainless 3D Printing Service

Stainless steel is one of the most popular industrial alloys ever produced. These alloys demand carefully maintained tooling and 3d printing. This is why there are a few stainless steel 3d printing services in the China.Be-Cu prototype Inc. stands tall among them. Our manufacturing professionals have a vast experience on DMLS (Direct Metal Laser Sintering) or SLM 3d printing technology of stainless steel alloys, which allow them to adjust the production process to gain maximum efficiency and achieve high productivity.View Be-Cu prototype learn our comprehensive stainless steel 3d printing of Technical specifications:

| Maximum Part Dimensions | 250 x 250 x 325 mm 250 x 250 x 275 mm (online orders) |

| Layer Thickness | Standard: 0.02 mm Performance: 0.04 mm |

| Minimum Wall Thickness | Standard: 1 mm Performance: 0.5 mm |

| Typical Accuracy | ± 0.02-0.05 mm |

| Recommended Minimum Wall Thickness | 20 μm 0.8 mil |

| Minimum Detail Size | 0.4 mm |

| Interlocking Or Moving Parts | No |

| Internal Channels | Yes |

| Surface Structure | Rough surface |

DCTG 6 of DIN EN ISO 8062-3 for dimensions between 0.5 and 30 mm

DCTG 8 of DIN EN ISO 8062-3 for dimensions between 30 and 400 mm

DIN ISO 2768-1 c (coarse) for dimensions between 0.5 mm and 400 mm

We, at Be-Cu prototype company, are committed to providing high-quality services at competitive prices. This commitment has brought us recognition as one of the leading 3D Printing services in the China. Our broad experience combined with our expertise has helped us take up various complex projects with ease. Our long list of happy and satisfied customers is the testament of our commitment to provide quality services at fastest turnaround times. Contact us or request a quote today about utilizing our stainless steel 3D Printing services.

Metal SLM 3D Printing Technical Parameters

- Maximum Forming Printing Size Of Metal 3D Printer: 250x250x325mm; 2. 3D printing layer thickness: 0.02mm~0.04mm;

- The Achievable Accuracy Of 3D Printing:Typical Accuracy: ±0.02-0.05 mm (Accuracy is related to geometry. It varies according to product size, printing direction, materials and post-processing methods.);

- Post-Processing: high temperature annealing, polishing, welding and other processing;

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Stainless Steel 3D Printing Parts & Case Studies

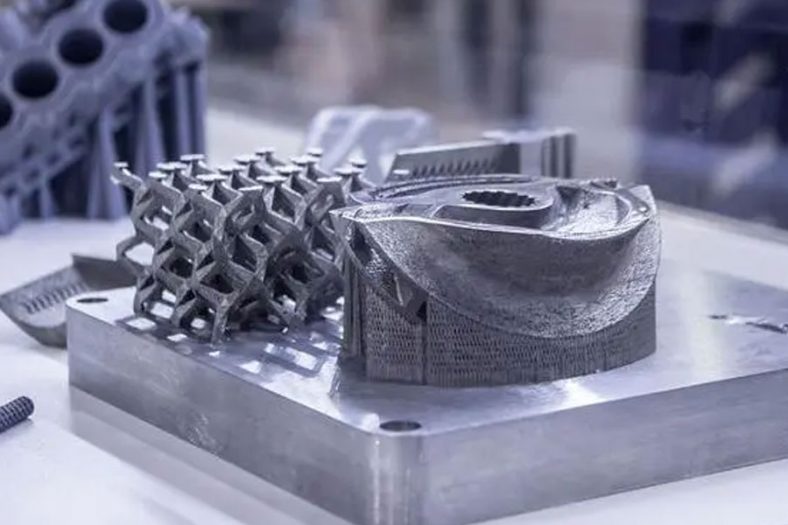

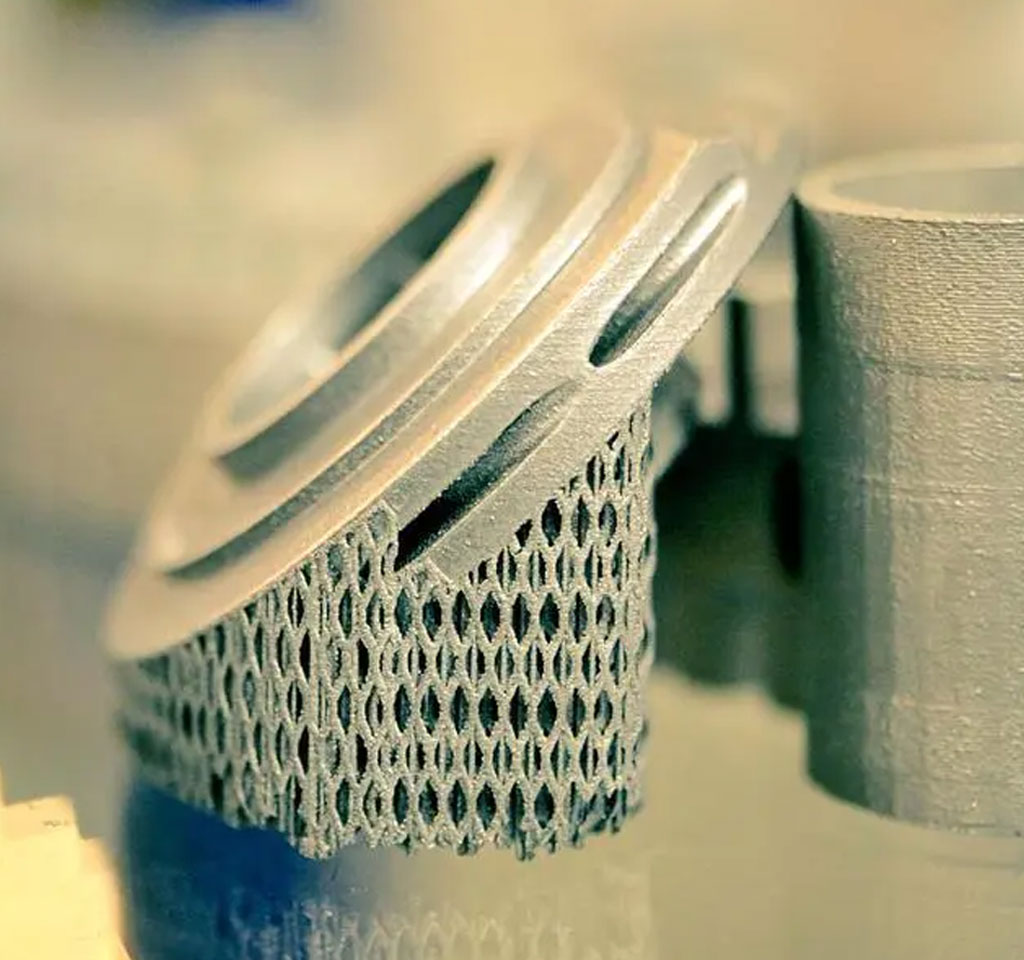

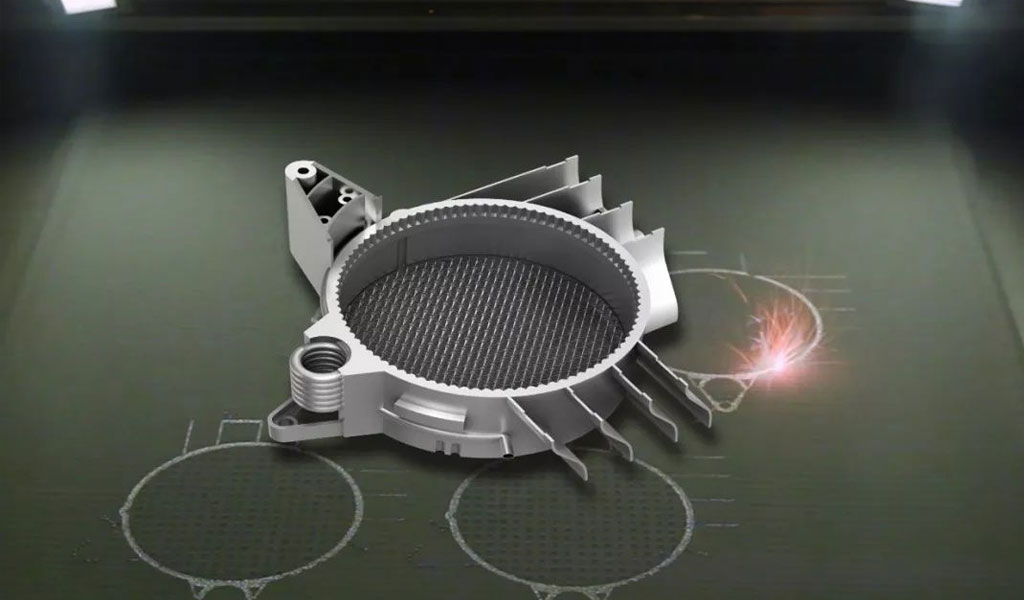

The metal 3D printer distributes even layers of metallic powder and the powdered metal is selectively melted to previous layers, which allows 3D metal parts to be fabricated of a bed of powdered metal. Using metal 3D printing allows us to produce parts with complex geometries that using traditional manufacturing methods not capable of and with materials that are difficult to process.Stainless Steel CNC Machining,Painting, sanding, shot blasting, powder coating and chrome plating secondary services available

-

3D Printing 316l Stainless Steel Fan Blade

-

3D Printing Stainless Steel Airplane Engine Model

-

3D Printing Small Stainless Steel Crafts

-

SLM 3D Printing Stainless Steel Quick Positioning Concentric Fixtures

-

SLM 3D Printing Stainless Steel Automobile Exhaust Pipe

-

3D Printed Stainless Steel Jet Turbine Blade

Stainless Steel Types We 3D Printing With

In 3D printing, stainless steel parts are typically produced using metal powder that consists primarily of stainless steel particles. However, there are variations in the specific stainless steel alloys used, depending on the desired properties of the final printed part. Here are some commonly used stainless steel materials in 3D printing:

316L Stainless Steel

17-4 PH Stainless Steel

15-5 PH Stainless Steel

304L Stainless Steel

2205 Duplex Stainless Steel

Custom Alloys

The selection of the stainless steel material for 3D printing depends on the specific application needs, including mechanical properties, corrosion resistance, thermal properties, and other desired characteristics.

The Features Of 3D Printing Stainless Steel

When it comes to 3D printing stainless steel, there are several notable features and characteristics that make it a popular choice for various applications. Here are some key features of 3D printing stainless steel:

- Strength and Durability: Stainless steel is known for its high strength and durability, and these properties are maintained in 3D printed stainless steel parts. This makes it suitable for applications that require robust and long-lasting components.

- Corrosion Resistance: Stainless steel is highly resistant to corrosion, which is one of its most valuable properties. 3D printed stainless steel parts exhibit excellent resistance to rust, tarnish, and other forms of corrosion. This makes them suitable for applications in harsh environments, including marine, chemical, and outdoor settings.

- Design Flexibility: 3D printing allows for intricate and complex geometries that may be challenging to achieve with traditional manufacturing methods. Stainless steel is well-suited for 3D printing, as it can be shaped into intricate designs and features, opening up new possibilities for component designs.

- High Temperature Resistance: Stainless steel has good resistance to high temperatures, making it suitable for applications that require components to withstand elevated operating temperatures without significant deformation or degradation.

- Material Availability: Stainless steel is widely available and offers a range of alloys with different properties. This ensures that designers and engineers have access to a variety of stainless steel options to meet their specific requirements.

- Post-Processing Options: 3D printed stainless steel parts can undergo various post-processing steps to enhance their properties or achieve specific finishes. These steps can include heat treatment, polishing, sandblasting, or coating, allowing for customization and refinement of the final parts.

- Material Recyclability: Stainless steel is a highly recyclable material. Any excess or unused stainless steel powder from the 3D printing process can be collected and recycled, reducing waste and promoting sustainability.

While 3D printing stainless steel offers many advantages, it also has some limitations. The process can be slower and more expensive compared to other 3D printing materials. Achieving fine details or specific surface finishes may also be challenging. Nonetheless, 3D printing stainless steel presents exciting possibilities for producing strong, durable, and corrosion-resistant components with complex geometries and design flexibility.

DMLS 3D Printing Stainless Steel Vs SLM 3D Printing Stainless Steel

DMLS (Direct Metal Laser Sintering) and SLM (Selective Laser Melting) are two commonly used 3D printing processes for stainless steel. While they share similarities, there are some differences between DMLS and SLM when it comes to 3D printing stainless steel. Here’s a comparison between the two processes:

1.Process

Both DMLS and SLM use lasers to selectively melt and fuse layers of stainless steel powder. The main difference lies in the approach to melting the powder. In DMLS, the laser partially melts the powder particles, allowing for the fusion of the particles while retaining some porosity. In SLM, the laser fully melts the powder particles, resulting in a denser and more fully fused part.

2.Material Properties

DMLS and SLM both produce stainless steel parts with similar material properties. The resulting parts exhibit high strength, good corrosion resistance, and mechanical properties comparable to conventionally manufactured stainless steel parts. The specific properties can depend on the stainless steel alloy used, the printing parameters, and the post-processing treatments applied.

3.Surface Finish

SLM generally produces parts with a smoother surface finish compared to DMLS. This is due to the complete melting and densification of the powder particles in SLM, resulting in fewer visible layer lines on the surface of the printed part. DMLS parts may have a more textured surface due to the presence of partially melted and fused powder particles.

4.Porosity and Density

DMLS parts typically have some degree of porosity due to the partially melted powder particles. While the porosity can contribute to certain advantages like weight reduction or improved thermal properties, it may require additional steps or considerations in applications where porosity is undesirable. SLM parts, on the other hand, tend to have higher density and reduced porosity due to the complete melting of the powder particles.

5.Design Considerations

Design considerations for DMLS and SLM are similar, focusing on factors such as support structures, heat dissipation, and part orientation. However, due to the differences in the melting process, DMLS may require different considerations to optimize part strength and porosity, while SLM may require more attention to achieving higher density and reducing residual stresses.

6.Applications

Both DMLS and SLM are used in similar applications where high-strength and corrosion-resistant stainless steel parts with complex geometries are required. They find use in industries such as aerospace, automotive, medical, and industrial manufacturing. The choice between DMLS and SLM may depend on specific application requirements, desired surface finish, and considerations related to porosity and density.

DMLS and SLM are both valuable 3D printing processes for stainless steel, offering similar material properties and applications. The choice between the two processes depends on factors such as surface finish requirements, desired density, and specific application needs.