Smart Audio Shell Parts And Base

- NO.: Aluminum 005

- Color: Custom

- Surface Treatment:Oxidation

- Product Material: Aluminum Alloy 6061

- Proofing Cycle:7 days(100000 pcs/M)

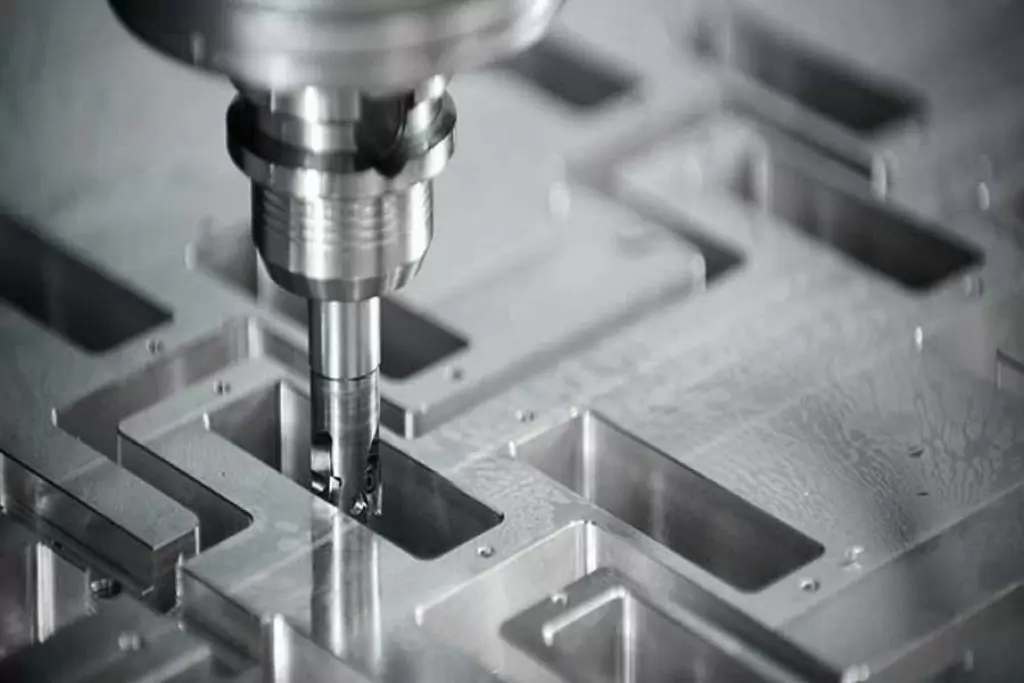

- Application:Precision Cnc Machining

- machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: Electronic Parts

- Production Process:Cnc Machining

- Size: According To Customer’s Drawings

High-Quality CNC Machining Smart Audio Shell Parts And Base

Today’s smart speakers have a very wide audience, including children teaching, middle-aged and elderly people for listening to music, and young people for controlling home appliances. According to survey data, sales of 70 million units will be exceeded in 2022; the rise of smart audio drives the audio shell industry. There are various audio kits on the market, and metal materials are very popular among the public. So, why do smart speaker shells use metal?

- Better sound quality: The greater the material density of the audio cover, the smaller the vibration generated by the cabinet when the sound is emitted, and the sound can be restored more realistically. Take aluminum alloy 6061 as an example, the density is 2.9g/ cm3; Moreover, the metal cavity has better sealing performance than other materials, the surround sound of the audio is stronger, and the output sound quality is better. Too-light speakers are prone to vibration and noise when playing songs, and the metal speaker shell can add weight to the body and avoid noise.

- High-end appearance: Nowadays, people are all visual animals, and they pursue beauty in everything; the texture of the metal shell is stronger, and the appearance is more upscale and fashionable; moreover, the metal surface is more resistant to dirt and easier to clean and maintain.

- Temperature resistance and sturdiness: Metal is not easily affected by the ambient temperature. If it is prone to thermal expansion and contraction, the sound tightness will be reduced, the shell will become loose, the parts will fall off, and the sound quality will also be affected by the sound; Take 304 stainless steel audio enclosure as an example, its high temperature resistance can reach 800℃, which is much higher than the heat dissipation temperature of general electronic appliances. In addition, the metal material is more resistant to external impact, stronger, and not easy to break.

- Thermal conductivity: Every electrical appliance needs heat dissipation, smart audio is no exception; the thermal conductivity of metal will be better, the thermal conductivity of aluminum alloy 6061 is (100℃) 16.3W·m-1·K -1, to ensure that the sound quality of the audio is not affected by heat; it can also prevent the parts inside from being damaged by long-term high temperature and prolong the service life of the product.

Be-cu Prototype Supply Machining services for electronics and Smart audio Shell Parts And Base manufacturing equipment component and parts. Aluminum, beryllium, brass, copper, Hastelloy®, Invar®, Inconel®, Monel®, nickel, niobium, rhenium, tantalum, titanium alloys, zirconium, stainless steel and other materials worked. Capabilities include machining, laser cutting, welding, milling, swaging, gun drilling, metal fabricating and prototyping.

The Advantages Of Custom Smart Audio Shell Parts And Base

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of CNC Milling Smart Audio Shell Parts And Base

| Material | Aluminum Alloy 6061/6063/7075 |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

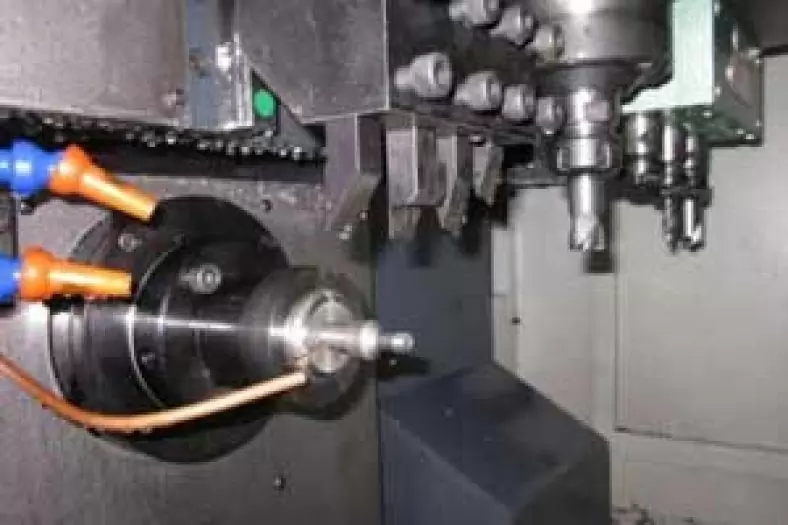

| Main Process | Milling, drilling, 5 axis cnc machining |

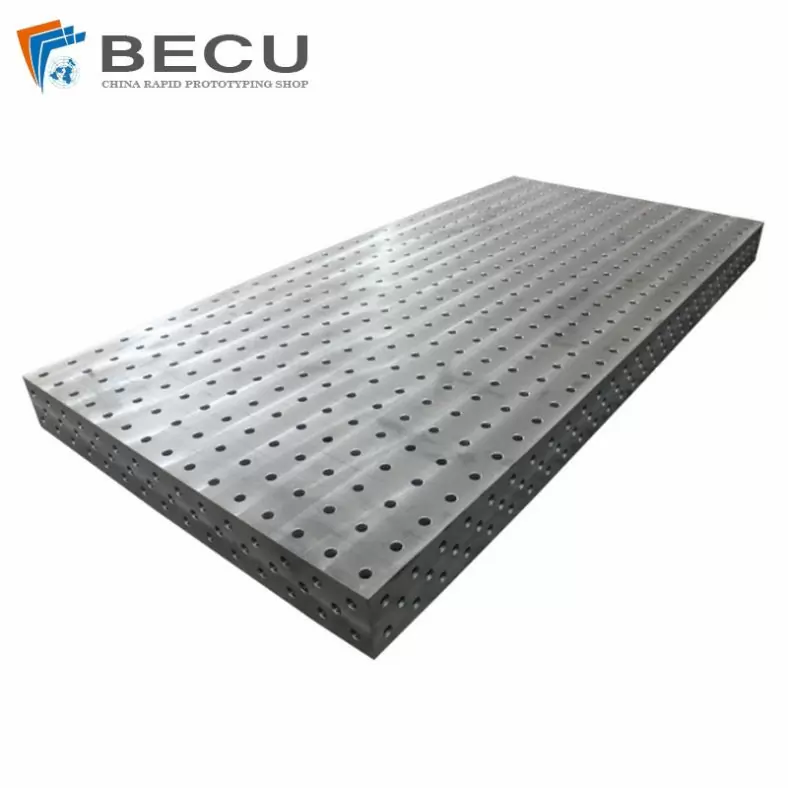

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Electronic And Smart Audio,IOT Field |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]