Water Aerator Impeller

- NO.: Aluminum 7075

- Color: Custom

- Surface Treatment:Oxidation

- Product Material: Aluminum Alloy

- Proofing Cycle:7 days(100000 pcs/M)

- Application: Water Aerator

- Machining Factory: Be-cu Rapid Prototyping Companies

- Product Category: Agriculture Parts

- Production Process: 5 Axis Cnc Machining

- Size: According To Customer’s Drawings

High-Quality Custom 5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

High-speed aerators are the most groundbreaking energy-saving and efficiency-enhancing products in the field of aquaculture in the past two years, and are widely loved by the market and users. While helping aquaculture fish and shrimp farming to save energy and increase efficiency, high-speed aerators also face a core problem: they are suitable for water depths of less than 2 meters and have limited usage scenarios.

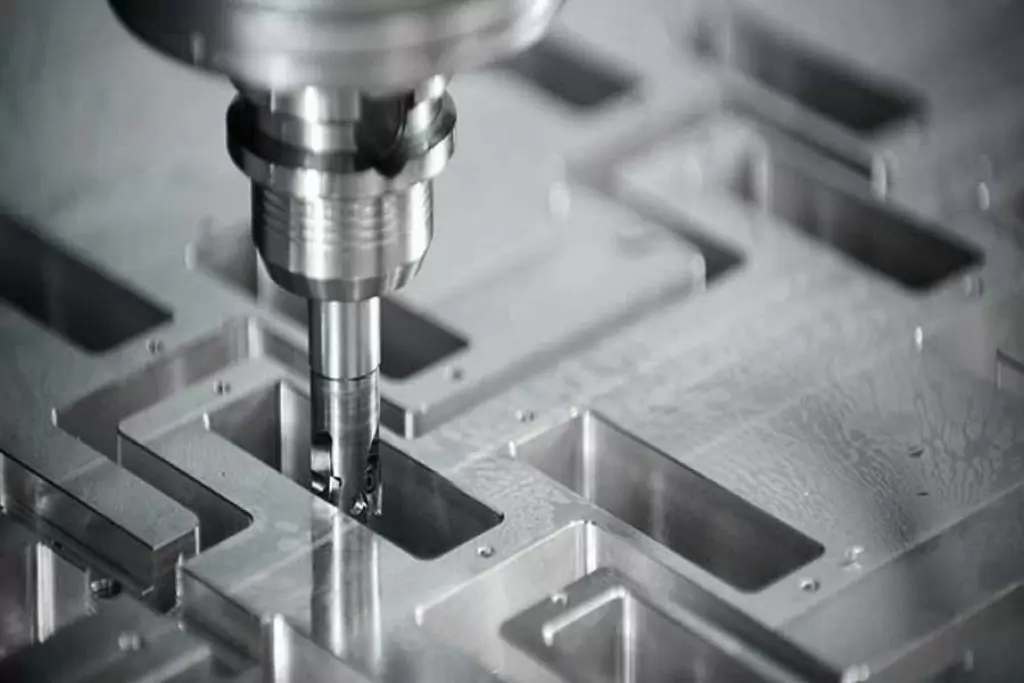

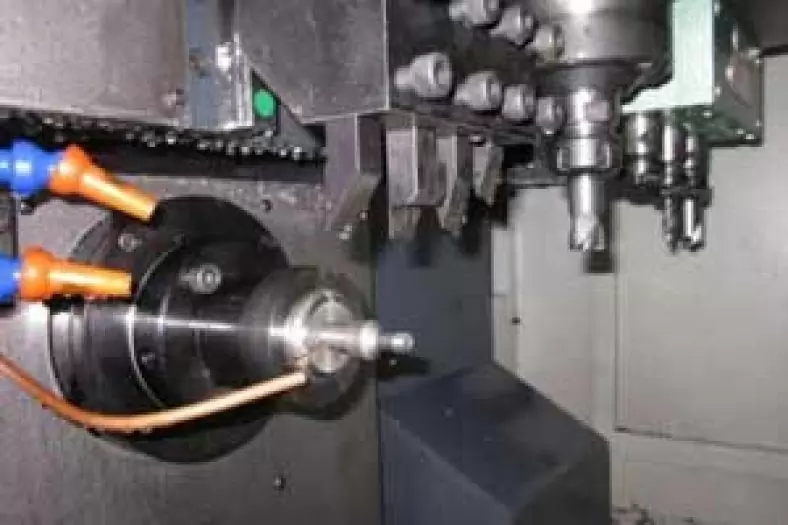

5-axis machining is a sophisticated and advanced method of manufacturing that enables the creation of complex and precise parts. This technique involves the use of a CNC (Computer Numerical Control) machine that operates on five different axes simultaneously, offering a higher degree of accuracy and flexibility compared to traditional 3-axis machining. One notable application of 5-axis machining is in the production of aluminum-magnesium alloy water aerator impellers, which are crucial components in various water aeration systems.

In 2022, based on market needs and breaking through technical difficulties, our customers developed and designed high-speed aerators suitable for 4-meter water depths, effectively broadening the use scenarios of high-speed aerators, and fully applicable to the current aquaculture fish and shrimp ponds, bringing good news to aquaculture users. BE-CU prototype company assists customers in using aluminum-magnesium alloy high-efficiency impellers processed by five-axis machining equipment, which run at high speed and are more efficient. The high-efficiency inverter has a speed regulation range of 0-1000hz, a wider speed regulation range, and ensures efficient operation of the equipment.

The integration of 5-axis machining in the production of aluminum-magnesium alloy water aerator impellers represents a significant advancement in manufacturing technology. This approach offers unparalleled precision, efficiency, and versatility, enabling the creation of high-performance components essential for various water aeration applications. By leveraging the unique properties of aluminum-magnesium alloys and the capabilities of 5-axis CNC machines, manufacturers can cnc machining impellers that meet the demanding requirements of modern water treatment and aeration systems.

Contact us today, and let’s bring your ideas to life!

The Advantages Of 5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of 5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

| Material | Aluminum 、 Stainless Steel、Carbon Steel、Inconel 、Alloy Steel、Tool Steel、Brass、Nickel etc |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom (Sand Blasting, Polishing, Spray painting, Pad Printing, Colour Electrophoresis, Mirror Finishing, Silk-Screen Printing, Oxidation) |

| Low Wax Casting Process | Casting Simulation、Tooling Making、Sample Developing、Production Schedule、Wax Injection、Welding、Shell Making、Dewaxing、Casting、Shell-removing, Cutting and Grinding、Surface Treatment、Value-added Services etc., |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Usage | Water Aerator Impeller,Custom By Be-Cu COM |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

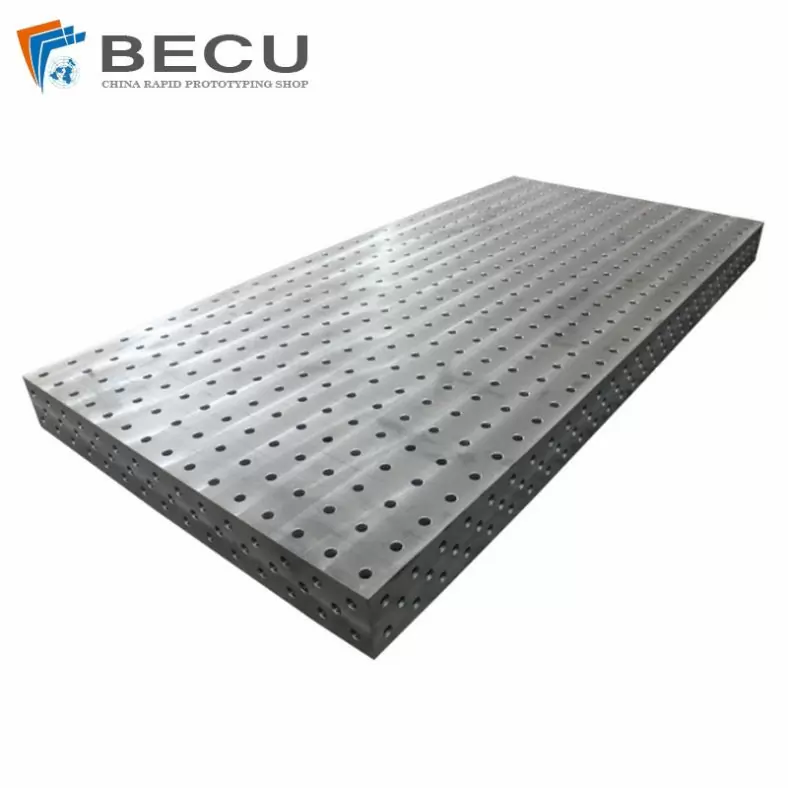

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]