Aluminum extrusions have revolutionized the world of structural design, offering engineers and designers unparalleled flexibility, strength, and cost-effectiveness. This article delves into the intricate details of three prominent aluminum extrusion profiles: 2020, 4040, and 8020.

The 2020 Aluminum Extrusion Profile

Aluminum extrusion profiles have found widespread use in various industries due to their versatility, strength-to-weight ratio, and ease of customization. The 2020 aluminum extrusion profile stands as one of the foundational profiles in this realm, serving as a benchmark for subsequent developments. Let’s explore the specifications, dimensions, applications, strengths, limitations, and real-world case studies associated with the 2020 extrusion profile.

Specifications and Dimensions:

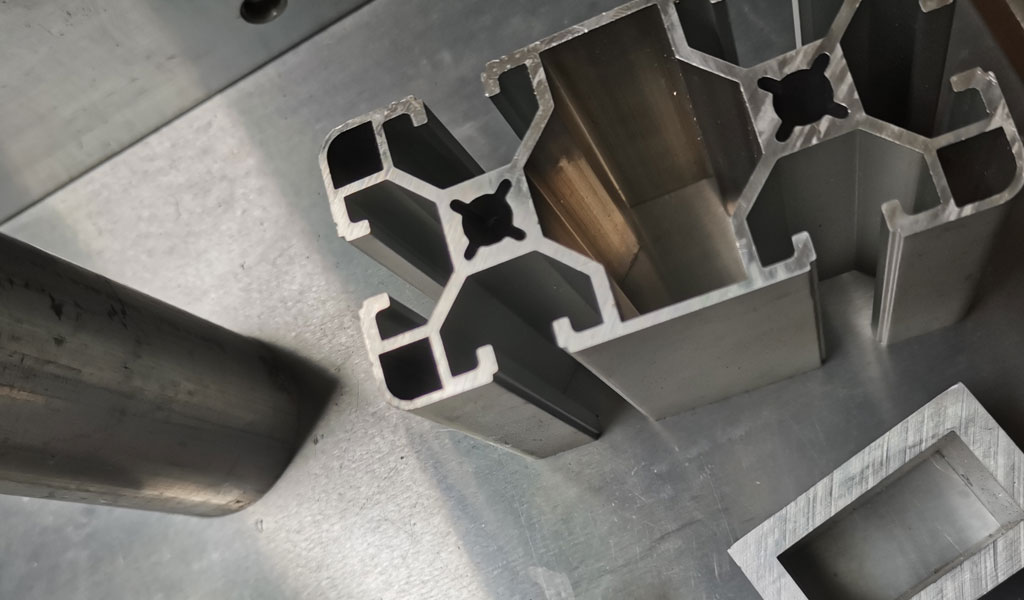

The “2020” in the aluminum extrusion profile’s name refers to the dimensions of the profile in millimeters. The profile has a cross-sectional shape resembling a square with equal sides of 20mm, hence the name “2020.” Its dimensions include:

- Outer dimensions: 20mm x 20mm

- Slot width: 6mm

- Center hole diameter: 4.2mm

- Wall thickness: Typically around 1.2mm

These specifications provide a basic understanding of the 2020 extrusion’s physical attributes, enabling engineers and designers to plan and incorporate it into their projects.

Common Applications:

The 2020 aluminum extrusion profile has found its place in a wide range of applications across industries:

- Structural Frameworks: It forms the backbone of various structures, including machine frames, workbenches, and support frames for automation equipment.

- Prototyping: Due to its accessibility and ease of use, the 2020 profile is popular for creating rapid prototypes of machines and devices before final production.

- Display Systems: In the retail sector, the profile is employed to construct modular shelving, display racks, and exhibition stands.

- DIY Projects: Enthusiasts and hobbyists utilize the 2020 profile for constructing everything from 3D printers and CNC machining machines to camera sliders and robotics platforms.

- Furniture: The profile’s sleek design makes it suitable for designing modern furniture pieces such as tables, desks, and storage units.

Strengths and Limitations:

The 2020 aluminum extrusion profile offers several advantages:

- Ease of Assembly: Its standardized dimensions and T-slot design simplify assembly, allowing components to be easily connected using bolts, nuts, and other accessories.

- Modularity: The T-slot design allows for the easy attachment of accessories, enabling the creation of complex structures with minimal effort.

- Lightweight Yet Sturdy: Aluminum’s inherent properties provide a favorable balance between weight and strength, making it suitable for a wide range of applications.

- Cost-Effective: The popularity of the 2020 profile ensures its availability at reasonable prices, making it an economical choice for various projects.

However, it also has some limitations:

- Limited Load-Bearing Capacity: While strong for its size, the 2020 profile may not be suitable for heavy-duty applications without additional reinforcement.

- Size Constraints: The 2020 profile’s compact dimensions might limit its use in projects requiring larger structural components.

Case Studies Utilizing 2020 Extrusions:

- Open-Source 3D Printers: Numerous open-source 3D printer designs use the 2020 profile as the frame structure due to its ease of assembly and modularity.

- Automated Conveyor Systems: Small-scale conveyor systems in industries like packaging and manufacturing utilize the 2020 profile for constructing the frame and guide rails.

- Electronics Workbenches: DIY electronics enthusiasts often create workbenches using the 2020 profile, integrating shelving and cable management features.

- Camera Sliders for Filmmaking: Camera enthusiasts design motorized camera sliders using the 2020 profile for smooth and controlled camera movements.

- Educational Robotics Platforms: Educational institutions use the 2020 profile to construct robotics platforms for teaching programming and automation concepts.

The 2020 aluminum extrusion profile has played a pivotal role in shaping various industries by providing a versatile and cost-effective solution for structural design needs. Its strengths in modularity, ease of assembly, and adaptability have made it a staple choice for engineers, hobbyists, and professionals alike. However, its limitations in load-bearing capacity and size constraints have driven the need for larger and more robust extrusion profiles, leading to the evolution of profiles like the 4040 and 8020. The next section will explore the advancements and advantages of the 4040 aluminum extrusion profile.

The Evolution to 4040 Aluminum Extrusion

As industries’ demands for more robust and versatile structural solutions grew, the aluminum extrusion landscape witnessed an evolution from the foundational 2020 profile to more substantial and capable profiles like the 4040. This section delves into the advancements in design, structural integrity, a detailed comparison of specifications and strengths, and the industries that have been transformed by the 4040 aluminum extrusion profile.

Advancements in Design and Structural Integrity:

The shift from the 2020 to the 4040 aluminum extrusion profile represents an evolution towards enhanced structural capabilities. While the 2020 profile was suitable for lighter applications, the 4040 profile introduces advancements in design that address the limitations of the previous profile. Key advancements include:

- Increased Load-Bearing Capacity: The larger cross-sectional area of the 4040 profile allows it to bear heavier loads while maintaining the advantages of aluminum’s lightweight nature.

- Enhanced Rigidity: The 4040 profile’s larger dimensions contribute to increased rigidity, making it better suited for applications requiring higher levels of stability.

- Versatile Accessory Compatibility: With a wider T-slot design, the 4040 profile facilitates the attachment of a broader range of accessories, offering more customization options.

- Reduced Deflection: The larger dimensions and increased wall thickness of the 4040 profile result in reduced deflection under load, improving overall performance.

A Comparison of Specifications and Strengths:

Let’s compare the specifications and strengths of the 4040 aluminum extrusion profile to its predecessor, the 2020 profile:

4040 Profile:

- Outer dimensions: 40mm x 40mm

- Slot width: 10mm

- Center hole diameter: 6.2mm

- Wall thickness: Typically around 2mm

Compared to the 2020 profile, the 4040 profile offers a considerable increase in dimensions, resulting in a more substantial and robust structure. This is reflected in its higher load-bearing capacity, improved rigidity, and expanded customization possibilities.

Industries Transformed by 4040 Extrusions:

The 4040 aluminum extrusion profile’s enhanced capabilities have led to its adoption in various industries:

- Industrial Automation: The 4040 profile forms the backbone of automated systems, such as conveyor belts, assembly lines, and robotic workstations, where durability and versatility are crucial.

- Heavy Machinery: Industries requiring heavy machinery, such as construction and manufacturing, utilize the 4040 profile to construct sturdy frames and support structures.

- Aerospace and Aviation: The profile’s strength-to-weight ratio makes it suitable for aerospace applications, including lightweight structural components and test rigs.

- Green Energy Solutions: Wind turbine frames, solar panel mounts, and energy storage systems benefit from the 4040 profile’s robustness and adaptability.

- Medical Equipment: Medical devices and laboratory setups often utilize the 4040 profile for constructing stable and customizable workstations and equipment racks.

- Research and Development: Prototyping and research laboratories take advantage of the 4040 profile’s flexibility to construct experimental setups and apparatuses.

- Retail Fixtures: Larger retail displays, shelving units, and modular store layouts benefit from the 4040 profile’s load-bearing capacity and customization options.

The transition from the 2020 to the 4040 aluminum extrusion profile represents a pivotal advancement in structural design. The 4040 profile’s enhanced dimensions, load-bearing capacity, and rigidity have opened doors to industries requiring robust and versatile structural solutions. As we move forward, we will explore the innovative 8020 aluminum extrusion profile, which pushes the boundaries of design even further, unlocking new possibilities for engineers, designers, and industries at large.

Unveiling the 8020 Aluminum Extrusion

The journey through aluminum extrusion profiles brings us to the pinnacle of structural innovation: the 8020 aluminum extrusion profile. As the name suggests, the 8020 profile continues the tradition of naming profiles after their dimensions, in this case, 80mm x 80mm. In this section, we’ll explore how the 8020 profile pushes the boundaries of design possibilities, delve into its unique features and specifications, and discuss its potential and foreseen applications across various industries.

Pushing the Boundaries of Design Possibilities:

The 8020 aluminum extrusion profile marks a significant leap in design possibilities and structural capabilities. Its larger dimensions allow for even more creative and versatile applications, particularly in projects where size, strength, and customization are paramount. Here are some ways in which the 8020 profile expands design boundaries:

- Greater Structural Integrity: The increased cross-sectional area of the 8020 profile offers exceptional strength, making it suitable for heavy-duty applications that demand robust support.

- Complex Frameworks: With its larger T-slot dimensions, the 8020 profile enables the integration of complex frameworks, intricate designs, and multidimensional structures.

- Enhanced Customization: The ample space within the T-slots allows for the integration of a diverse range of accessories, enhancing functionality and adaptability.

- Expanded Load-Bearing Capacity: The 8020 profile’s size and strength make it capable of supporting heavier loads, making it a preferred choice for applications requiring substantial weight distribution.

Unique Features and Specifications:

The 8020 aluminum extrusion profile boasts distinctive specifications that set it apart:

8020 Profile:

- Outer dimensions: 80mm x 80mm

- Slot width: 10mm

- Center hole diameter: 10.2mm

- Wall thickness: Typically around 4mm

Compared to its predecessors, the 8020 profile’s larger dimensions translate into increased strength, load-bearing capacity, and rigidity. Its T-slot design remains consistent, allowing for compatibility with a wide range of existing accessories.

Potential and Foreseen Applications:

The capabilities of the 8020 aluminum extrusion profile are poised to reshape industries and foster innovation in various ways:

- Heavy Machinery and Equipment: The 8020 profile is ideal for constructing frames, supports, and enclosures for heavy machinery used in construction, manufacturing, and mining.

- Large-Scale Automation: In the realm of factory automation, the 8020 profile supports the creation of comprehensive conveyor systems, assembly lines, and robotic workstations.

- Aerospace and Defense: The profile’s robustness makes it suitable for aerospace applications, including building aircraft components and specialized testing equipment.

- Research and Development Labs: Research facilities can leverage the 8020 profile to construct advanced experimental setups, ergonomic workstations, and instrument racks.

- Architectural Structures: The 8020 profile can be integrated into architectural designs for building facades, unique staircases, and other large-scale structural elements.

- Green Energy Infrastructure: Renewable energy projects, such as large solar panel arrays and wind turbine supports, benefit from the 8020 profile’s durability.

- Transportation: The profile can contribute to the construction of specialized vehicles, trailer frames, and transport containers.

- Entertainment and Events: Staging systems, event structures, and concert rigging can utilize the 8020 profile’s stability and adaptability.

As industries continue to evolve, the 8020 aluminum extrusion profile will be at the forefront of enabling innovative solutions that demand superior strength, durability, and flexibility. Its adaptability to diverse applications positions it as a key player in shaping the future of structural design across industries.

From the foundational 2020 profile to the robust 4040 and the innovative 8020 profiles, aluminum extrusions have revolutionized how we approach structural design. Each profile’s evolution has been driven by the ever-changing demands of industries and the desire for stronger, more adaptable solutions. As we stand at the cusp of new technological advancements, one thing is certain: aluminum extrusions will continue to be instrumental in shaping the way we build, create, and innovate.

Comparative Analysis: 2020 vs. 4040 vs. 8020 Aluminum Extrusion Profiles

As we navigate the realm of aluminum extrusion profiles, a comprehensive comparative analysis between the foundational 2020, the advanced 4040, and the groundbreaking 8020 profiles provides valuable insights into their respective strengths, capabilities, and potential applications. In this section, we delve into crucial factors such as strength-to-weight ratio, rigidity, versatility, cost considerations, and sustainability, offering a well-rounded perspective on these profiles’ comparative merits.

Strength-to-Weight Ratio:

The strength-to-weight ratio is a critical metric that gauges how much load a material can support relative to its weight. In the context of aluminum extrusion profiles, this ratio highlights the structural efficiency of each profile.

- 2020: The 2020 profile offers a commendable strength-to-weight ratio, making it suitable for applications that require moderate load-bearing capabilities while maintaining a lightweight design.

- 4040: With increased dimensions and wall thickness, the 4040 profile improves upon the 2020’s ratio, providing greater strength without a substantial increase in weight.

- 8020: The 8020 profile continues the trend, boasting an impressive strength-to-weight ratio owing to its larger dimensions and robust design.

Rigidity and Load-Bearing Capacity:

Rigidity determines how much a material resists deformation under applied loads. In conjunction with load-bearing capacity, it showcases the profiles’ ability to withstand heavy loads without excessive flexing or bending.

- 2020: While the 2020 profile demonstrates good rigidity for its size, its load-bearing capacity might limit its use in applications demanding substantial weight support.

- 4040: The 4040 profile’s increased dimensions translate to enhanced rigidity and improved load-bearing capacity, catering to heavier applications.

- 8020: With its larger cross-sectional area, the 8020 profile excels in both rigidity and load-bearing capacity, accommodating heavy-duty requirements.

Versatility and Adaptability:

Versatility encompasses the range of applications a profile can serve, while adaptability reflects its capacity to accommodate changing project needs and configurations.

- 2020: The 2020 profile’s compact size and modularity make it versatile and well-suited for prototyping, DIY projects, and smaller-scale applications.

- 4040: Building upon the 2020’s foundation, the 4040 profile enhances versatility, accommodating more complex frameworks and larger structures.

- 8020: The 8020 profile’s ample dimensions provide unparalleled versatility, enabling the construction of intricate designs and extensive applications.

Cost Considerations and Affordability:

Cost is a crucial factor in any engineering project. Profiles that offer the right balance between features and price often gain favor.

- 2020: The 2020 profile is generally the most affordable option due to its smaller dimensions and wide availability.

- 4040: The 4040 profile offers increased capabilities while maintaining a reasonable price point, making it an attractive choice for medium-duty projects.

- 8020: As the most robust profile, the 8020 might come with a higher price tag, particularly suited for applications that demand its enhanced features.

Sustainability and Eco-Friendly Aspects:

In an age where sustainability is paramount, considering the environmental impact of materials and processes is crucial.

All Profiles: Aluminum extrusion is inherently sustainable due to aluminum’s recyclability. All profiles can be recycled and repurposed, contributing to a circular economy.

The comparative analysis of the 2020, 4040, and 8020 aluminum extrusion profiles underscores their evolution and potential. While the 2020 profile serves as a foundational option, the 4040 and 8020 profiles push boundaries with increased dimensions, strength, and adaptability. Project requirements, load considerations, and budget constraints will ultimately determine the optimal profile for any given application. As we embrace the future of structural design, the remarkable journey from 2020 to 4040 and 8020 profiles showcases the ongoing innovation that shapes industries and enables creative engineering solutions.

Choosing the Right Extrusion Profile:

Selecting the ideal aluminum extrusion profile for a project involves a careful evaluation of various factors. This decision significantly impacts the project’s functionality, aesthetics, and cost-effectiveness. This section delves into the critical factors influencing profile selection, the role of design flexibility and customization, and the concept of future-proofing designs beyond even the innovative 8020 profile.

Factors Influencing Profile Selection:

- Load Requirements: The anticipated load and stress that a structure will experience play a pivotal role in profile selection. Heavier loads typically necessitate profiles with higher load-bearing capacities, such as the 4040 and 8020.

- Application Type: Different industries and applications require varying levels of structural integrity and versatility. Consider the scale, purpose, and conditions under which the structure will operate.

- Budget Constraints: Budget considerations often guide profile choices. While the 2020 profile is more affordable, the 4040 and 8020 profiles offer greater capabilities at a potentially higher cost.

- Project Size: The scale of the project determines how profiles will be joined and assembled. Larger projects might necessitate profiles with enhanced rigidity and stability, like the 4040 and 8020.

- Customization Needs: Some projects demand intricate designs and precise configurations. Profiles with larger dimensions, like the 4040 and 8020, offer more room for customization.

- Future Expansion: Anticipating future modifications or expansions is crucial. Opting for a profile with room for adjustment, like the 4040 or 8020, can save time and resources down the line.

Design Flexibility and Customization:

Design flexibility is a critical consideration when choosing an aluminum extrusion profile. The T-slot design of these profiles allows for easy attachment of accessories and additional components, enabling customized solutions. Profiles like the 4040 and 8020, with wider slots, offer increased options for integrating various elements such as brackets, connectors, panels, and more. This adaptability not only enhances functionality but also facilitates aesthetic enhancements.

Designers can innovate freely, creating tailored solutions that cater to specific project needs. This flexibility extends to both structural and aesthetic aspects, enabling seamless integration of functional elements and distinctive designs.

Future-Proofing Your Design: Looking Beyond 8020:

The 8020 aluminum extrusion profile represents a remarkable feat in structural design, but innovation never rests. As industries continue to evolve, engineering requirements will change as well. While the 8020 profile currently pushes the envelope in terms of capabilities, it’s important to consider the possibilities of the future.

Designs should be future-proofed to accommodate upcoming technologies, processes, and applications. While the 8020 profile might be cutting-edge today, staying attuned to industry trends, technological advancements, and emerging materials can ensure that your design remains adaptable and relevant in the face of rapid change.

The process of selecting an aluminum extrusion profile is a blend of art and science, influenced by project-specific needs, practical considerations, and forward-looking vision. The right profile choice balances load requirements, customization needs, budget considerations, and adaptability for future growth. As engineers and designers continue to push boundaries, these profiles become essential tools in translating imagination into reality, enabling us to build the future we envision.