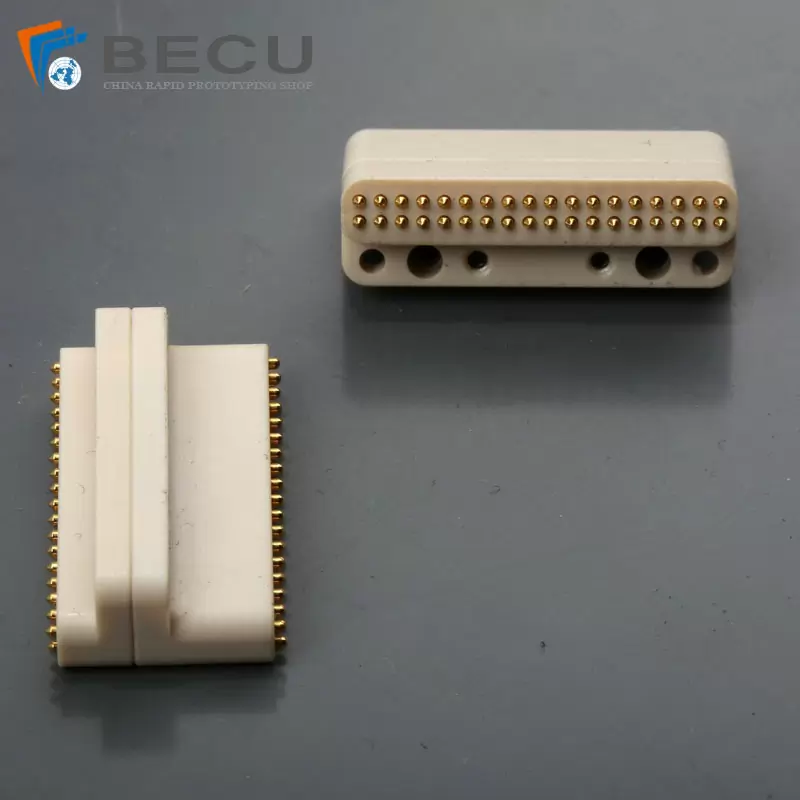

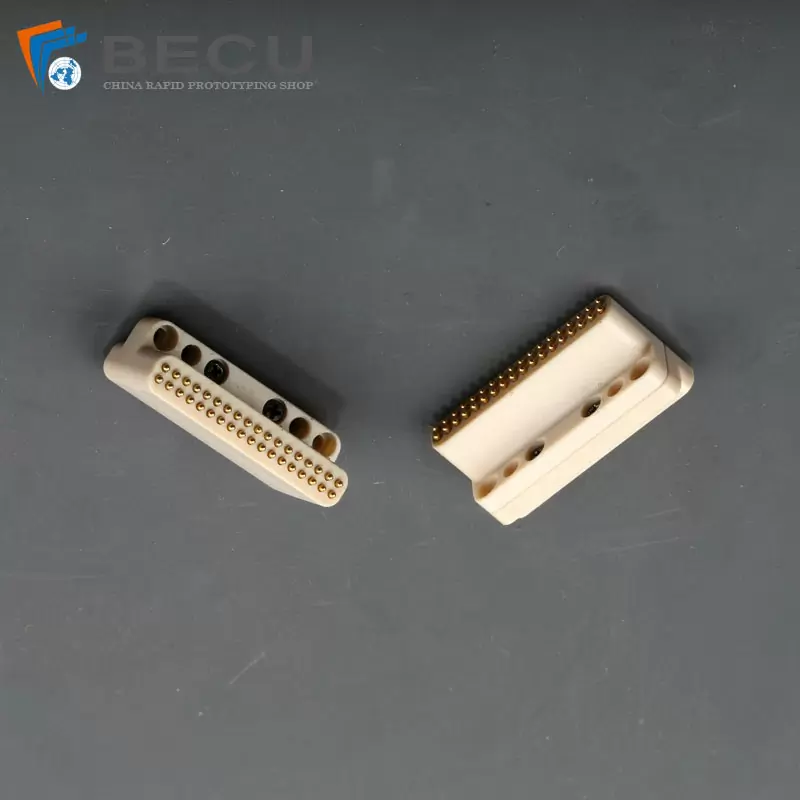

PEEK Module Probe Block

- Product Name: PEEK Parts

- No+Color:Custom

- Surface Treatment: Oxidation

- Product Material: Plastic

- Proofing Cycle:7 days(100000 pcs/M)

- Application:Precision PEEK Machining

- machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: Module Probe Block

- Production Process: Microhole Machining

- Size: According To Customer’s Drawings

High-Quality Microhole Machining PEEK Module Probe Block

ISO 9001 and AS 9100 certified. Module Probe Block Microhole Machining services for PEEK. Also works with ABS, acetal, nylon, phenolic, acrylic, polycarbonate, polyetherimide, polyethylene, PTFE, ceramic, PVC, polystyrene and wood. Various machining processes include boring, countersinking, drilling, internal forming, knurling, milling, cutting, turning, threading and tapping. Secondary services such as anodizing, grinding, heat treating, passivating, plating and welding provided. Prototype to specialty, low to high volume and small to large production runs offered. Serves the aerospace, agricultural, architectural, chemical, electronics, marine, medical, military, optical and pharmaceutical industries. AutoCAD and SolidWorks® files accepted.

The Advantages Of Microhole Machining PEEK Module Probe Block

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Microhole Machining PEEK Module Probe Block

| Material | PEEK |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Milling, drilling, 5 axis cnc machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Electronic |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

PEEK (Polyether ether ketone) is a strong, stiff plastic material that is often used in applications where performance at elevated temperatures is required. PEEK has outstanding chemical resistance as well as resistance to steam and hot water.Be-cu.com is a supplier of CNC machined PEEK and laser cutting peek parts, and has been for decades. Using high-speed and very precise CNC turning and milling, we supply PEEK parts made from sheet, rod, and tube for use in medical, aerospace, semi-conductor, oil and gas, and food and beverage industries.We has expanded its machining capabilities to include Polyether ether ketone (PEEK) injection and molding capabilities. Our dedicated PEEK process allows us to provide our customers with machining plastic prototypes and low volume production parts for new designs, as well as molded components for high volume production.

Our parts are manufactured using no cutting fluids; thus, they are machined dry to keep burrs to a minimum and to reduce the risk of contaminants. If you're in the need for PEEK parts, contact Be-cu.com today!

-

Precision Engraving Special-Shaped Natural Color PEEK Parts

-

5 Axis Machining Black PEEK Plastics Chip Mount Base

-

5 Axis CNC Precision Machining PEEK Valve Body And Impeller

-

Microhole Machining PEEK Module Probe Block

-

5 Axis Machining PEEK Plastics Mechanical Hub

-

Precision CNC Turning Machining PEEK Plastic Fasteners

-

ISO 9001:2015 Certified Machining PEEK Balance Impeller

-

5 Axis Machining Special Engineering PEEK Plastic Parts