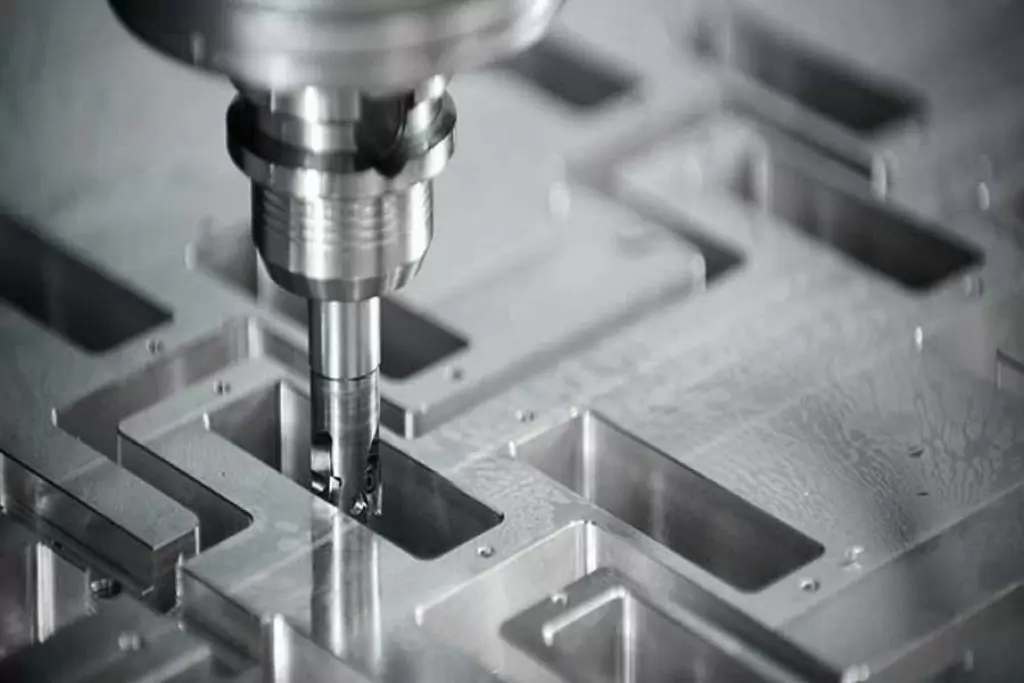

Since the 1980s, the spindles of CNC machine tools and machining centers have developed at a high speed.

The mechanical structure of the main drive of the high-speed CNC machine tool has been greatly simplified, the D-belt drive and gear drive are cancelled.

And the machine tool spindle is directly driven by the built-in motor, thereby shortening the length of the machine tool main drive chain to zero, enjoying the main movement of the machine tool.

The “zero transmission” of this structure is called an electric spindle. It has the advantages of compact structure, high mechanical efficiency, extremely high rotation speed, low vibration and low vibration, so it has been widely used in modern CNC machine tools. In foreign countries, the electric spindle has become a high-tech high-tech product of mechatronics, such as FISCHER in Switzerland, MN in Germany, PRECISE in the United States, GAMFIOR in Italy, and NSK in Japan. company and KOY () company, Sweden’s SKF company, etc.

The Structure Of The Electric Spindle Of The CNC Machine Tool

The electric spindle of the CNC machine tool is composed of a casing motor, a main shaft, a bearing, a main shaft unit casing, a drive module and a cooling device. The main shaft is supported by two sets of front and rear ball bearings. The rotor of the CNC machine tool motor is installed on the main shaft of the machine tool by means of press fitting, between the front and rear bearings, and the friction force generated by the press fitting realizes the transmission of large torque.

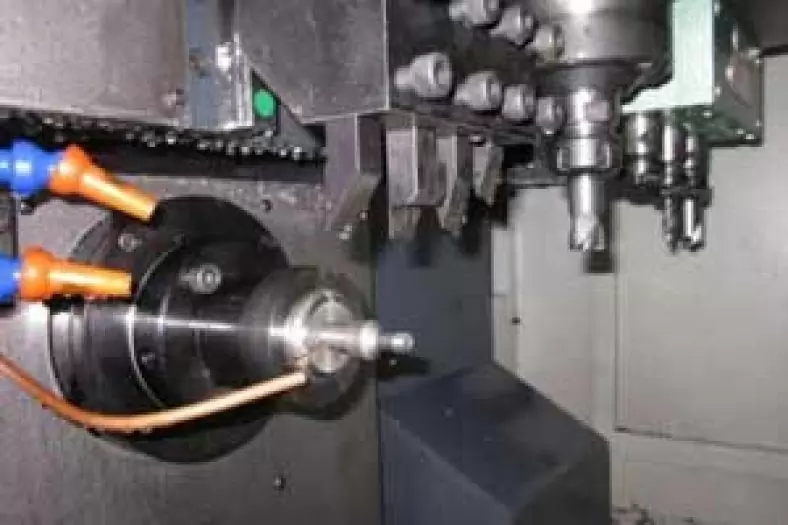

The stator of the motor of the CNC machine tool is installed in the casing of the spindle unit through the cooling jacket. In this way, the rotor of the motor is the main shaft of the machine tool, and the box of the electric main shaft is the motor seat, which becomes a new type of main shaft system of mechatronics.

The speed change of the spindle is controlled by the spindle drive module, and the spindle unit device is limited. The back end of the spindle is equipped with speed measuring and angle measuring displacement sensors, and the inner cone at the front end }L and the end face are used to install the tool.

Bearings Of The Electric Spindle Of CNC Machine Tools

Bearings are the key components that determine the life and bearing capacity of the spindle, and their performance is extremely important to the use of the motorized spindle. At present, the bearings used in the electric spindle of CNC machine tools mainly include ceramic pressure bearings and magnetic suspension bearings.

The rolling elements of ceramic ball bearings are made of ceramic materials, and the inner and outer rings are still made of bearing steel. The ceramic material is Sl, which has the advantages of light weight, low thermal expansion rate, and large elastic modulus (lj times that of general bearings). If the ceramic rolling elements are used, the centrifugal force and inertial slip of the bearing can be greatly reduced, which is beneficial to increase the spindle speed.

Magnetic bearings rely on multiple pairs that are 180 to each other on the circumference. The magnetic poles generate radial suction (or repulsion) to suspend the main shaft in the air, so that the journal and the bearing do not touch left and right. After bearing the load, the spatial position of the main shaft will change slightly. The control device changes the suction force of the corresponding magnetic pole according to the change value of the main shaft position detected by the position sensor, so that the main shaft can quickly return to the original position, so as to ensure that the main shaft always rotates at high speed around its inertial axis. , so it has good high-speed performance and high precision, but it is rarely used due to its high price.

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]