Power Problem

-Possible reasons: Unstable power supply, power line failure or power switch problem.

- Solution:

- Check whether the power socket is powered on and make sure the power supply is normal.

- Check the power line to eliminate damage or short circuit.

- Check the power switch to ensure it is working properly.

- If necessary, work with an electrician to perform further inspection and maintenance of the power system.

Control System Failure:

- Possible reasons: Control system hardware or software failure.

- Solution:

- Check whether there is an alarm message on the control panel to understand the specific cause of the failure.

- Restart the control system. Sometimes a simple restart can solve some temporary faults.

- If there is a software problem with the control system, the software may need to be reloaded or updated.

- If necessary, contact the manufacturer’s technical support or professional repair team for further diagnosis and repair.

Electrical System Failure:

- Possible reasons: Failure of electrical components, such as circuit breakers, relays, etc.

- Solution:

- Check circuit breakers and relays to make sure they are not tripped or damaged.

- Check electrical connections for potential breaks or shorts.

- If any electrical component failure is found, replace or repair it in time.

Machine Tool Failure

- Possible reasons: Problems with the machine tool itself, such as failures in guide rails, screws, drive systems, etc.

- Solution:

- Check the machine tool guides to make sure they run smoothly and are not stuck.

- Check the screw and drive system to make sure they are not damaged or severely worn.

- Check the drive system to ensure that the motor and driver are working properly.

- If there is a problem with the machine tool, it may be necessary to work with the manufacturer or professional technicians for repairs.

Program Error:

- Possible reasons: Errors or inconsistencies in the program may prevent the wire EDM from starting correctly.

- Solution:

- Check the processing program to ensure there are no grammatical errors or logical errors.

- Make sure the parameters in the program match the actual configuration of the wire cutting machine.

- If necessary, rewrite or modify the program and test it.

Internal Mechanical Problems Of Wire Cutting Machine

- Possible reasons: Damage or failure of internal mechanical components.

- Solution:

- Conduct a thorough inspection of the mechanical parts of the wire cutter to look for potential problems.

- If necessary, repair or replace damaged mechanical parts.

Example 8-17 The yarn storage drum is not reversed, causing the machine to stop all the time.

Possible cause: The travel switch SQ3 or SQ2 is damaged.

Remedy: change the travel switch SQ3 or SQ2.

Example 8-18 The yarn storage drum is often stopped when the direction is reversed.

Possible reasons: The electrode wire is too loose; the broken wire protection circuit is faulty.

Method of exclusion:. Tighten the electrode wire; replace the broken wire protection relay.

Example 8-19 The wire storage drum does not rotate (the SBI does not respond when the wire feeding button is pressed).

Possible reasons: the external power supply has no voltage; the resistance Y. Blown; the bridge rectifier vc of the CNC lathe is damaged, causing the fuse FUi to blow.

Remedy: check the external power supply and remove it; replace the resistance Yl with the CNC lathe; replace the rectifier vc with the CNC lathe, and the fuse FU. .

Example 8-20 The wire storage drum does not rotate (the wire feeding voltage is indicated and is higher than that in normal operation):

Possible reasons: carbon brush wear or rotor dirt: The power supply line of the CNC lathe motor M is broken.

Remedy: replace the carbon brush, clean the motor rotor; check the incoming wire and remove it.

Example 8-21 The work light is not on.

Possible cause: Fuse FU2 is broken

Remedy: replace fuse FU2.

Pour 8-22 working fluid pump does not rotate or rotates slowly.

Possible reasons: The working contactor KM3 of the liquid pump does not pull in; the capacitor of the working liquid pump is damaged or the capacity is reduced.

Remedy: press SB4, if there is 115V voltage at the two ends of the KM3 wire package, replace the KM3. If there is no J15V voltage on the CNC lathe, check and control the KM3 wire package circuit: replace the capacitor of the same specification or add a capacitor with sufficient voltage resistance.

Example 8-23 The high-frequency power supply is normal, the wire is running normally, and there is no high-frequency spark (the simulation does not run during normal operation and cutting).

Possible reasons: If the high-frequency relay Kj does not work, the normally closed contact of the travel switch SQ3 is broken; if the high-frequency relay Ki can be pulled in, the CNC lathe is because the high-frequency relay contact is broken or the high-frequency output line is broken.

Remedy: choose the travel switch sQj; change the high-frequency relay K, check the high-frequency power output line with the CNC lathe, and eliminate the open circuit fault.

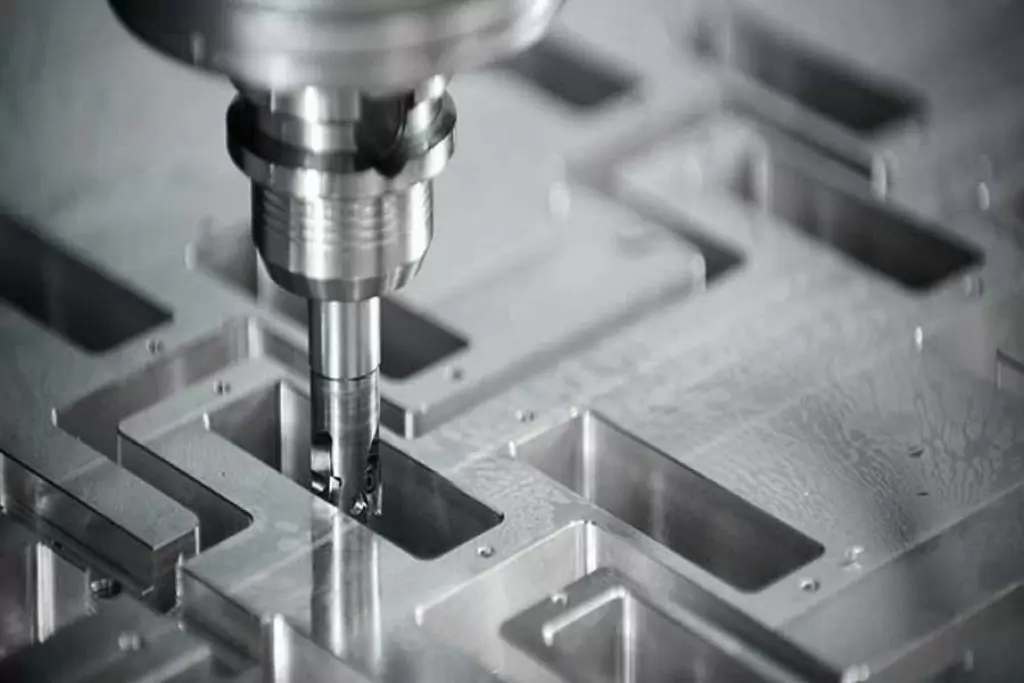

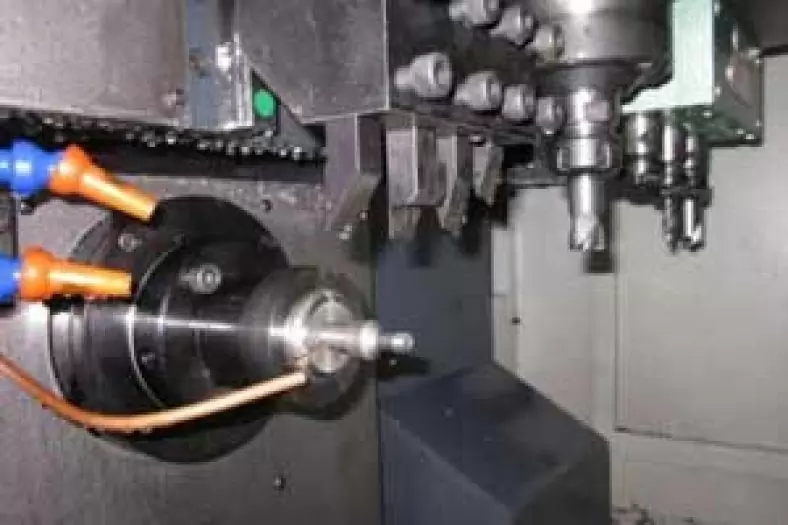

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]