Data backup of CNC machine tool maintenance in Shenyang Machine Tool Factory Because sln840cmmc-cpu combines the computing hard disk and the data management method of the computer dos operating system, the data management of sln840c is very different from the rest of the sln800 series systems. After software version 3, all system programs (nck and plk) of sln840c are stored on the hard disk, that is, during the system startup process, mmc loads the boot and system programs for nck-cpu and plc-cpu, the system completes startup, mmc Then load all the processing programs and data in the user/LOcal/STANDAED workpiece directory on the hard disk into the nck memory.

The programs required for work processing can be set by the machine tool manufacturer and placed in the standard directory. In this way, after the system is started, the operator can directly process the workpiece. All china cnc machining machine data, setting data, plc programs can also be backed up on the mmc hard disk. This makes the sln840c very different from other sln800 series systems. For other sln800 series systems, after the battery is powered off, all data must be re-input through the programmer. In sln840c, it is enough to reload the numerical control on the hard disk.

The machine CNC is backed up with savetodisk software in the dlagnosls/start-up/machinesata/file function area. At this time, the screen will ask you to enter a new file name, and then press the ok software to save the CNC machine tool to the file you named. The file can be reloaded with the loadfromdisk software in the same area, or saved to disk via CNC I/O. Setting data is stored or loaded with savenc or loadnc software in the servlces/nc area.

Local Backup

Local backup refers to saving data in the storage device of the CNC machine tool (such as disk, USB flash drive, etc.) to achieve offline backup.

U disk backup

Insert the data into the USB interface of the CNC machine tool through the U disk, and copy the data directly to the U disk for backup. This backup method is simple and easy, but the storage capacity of the USB flash drive may be limited and the backup is limited.

Network hard disk backup

Connect the CNC machine tool to the network hard drive and back it up through network sharing. This method can achieve flexible backup, but it requires network hardware support, and backup will fail when the network fails or authorized access is restricted.

Network Backup

Network backup refers to uploading data to the data center through the network for backup. In CNC machine tools, common network backup methods include FTP, SCP and SFTP.

FTP backup

FTP is a file transfer protocol based on TCP/IP protocol and is commonly used for file transfer on the Internet. CNC machine tool data can be uploaded to a remote FTP server for backup through FTP. This method requires setting the IP, port and other information of the FTP server in advance, as well as setting the username and password for uploading.

SCP backup

SCP is the abbreviation of Secure Copy and is a secure file transfer protocol. SCP ensures the security of data transmission through encryption technology. With SCP backup, data cannot be leaked or tampered with.

Cloud Backup

Cloud backup refers to backing up data to cloud storage centers, such as Alibaba Cloud, Tencent Cloud, etc., to achieve long-term data backup and disaster recovery.

Alibaba Cloud OSS backup

Alibaba Cloud OSS is an object storage service that provides long-term, secure, and stable cloud storage services for users’ data. By using Alibaba Cloud OSS for backup, data can be retained in the cloud for a long time, avoiding the risk of data loss due to local storage failures or disasters.

Tencent Cloud COS backup

Tencent Cloud COS is a cloud storage service that provides a simple, efficient and secure data storage solution. Using Tencent Cloud COS for backup, data backup can be stored in the cloud, and data recovery can also be easily performed.

The above are several methods for backing up CNC machine tool data. Different backup methods are suitable for different scenarios. In actual operation, the choice should be made according to the specific situation to ensure the reliability and continuity of data backup.

The plc program is stored in the form of machine code on the mmc hard disk. The storage location is the plc/plc/data/anw-prog file in the services/datamanagement area. The plc program can only be stored in the generalreset screen. The saveplc soft key saves all programs in the current plc-cpu memory to the anw-prog file on the hard disk, and the plcreset soft key implicitly loads the anw-prog file into the plc-cpu memory.

Generally speaking, after the machine tool manufacturer completes the design of the machine tool, the above data should be backed up on the hard disk, and at the same time, a floppy disk containing all the data should be left to the end user for the user to use during maintenance.

After the user accepts the machine tool, if possible, the above data should be backed up, just in case. In addition, Siemens has not provided a hard disk backup function for sln840c – tape drive (streamer), this function is to back up all the data on the hard disk (including the dos system) to the tape. The tape is generally 160mb or 600mb, and the entire hard disk can be backed up, but this function requires a valitek tape drive.

The data on the floppy disk can be used by the user to restore the system when the system battery is powered off and the nc-cpu and plc-cpu boards are faulty. However, when the mmc-cpu board fails, the mmc-cpu board needs to be replaced. At this time, the user still wants to restore the original version of the system software, especially when the machine tool has special functions, only the original backup tape can be used to restore the machine tool operation.

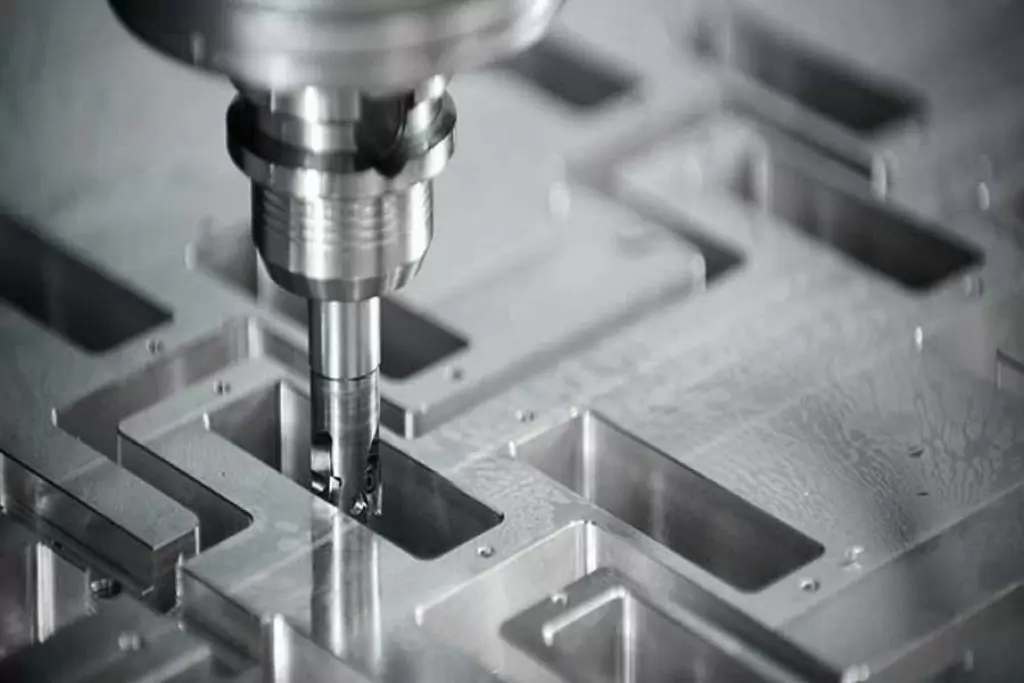

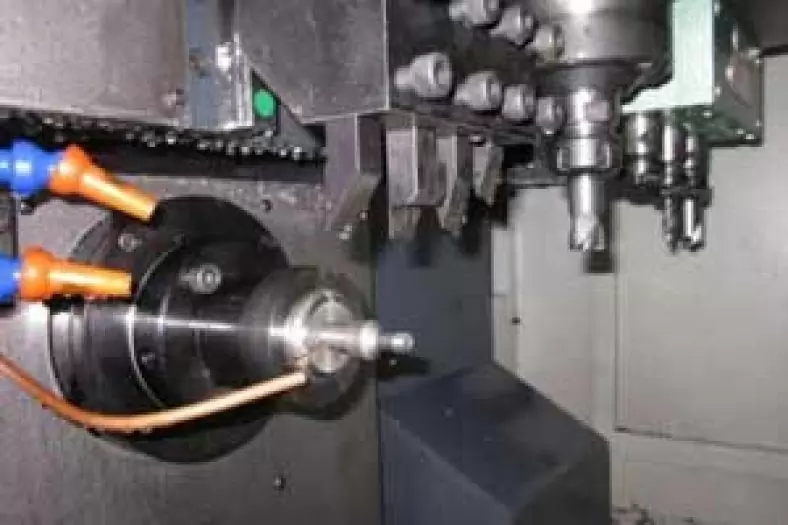

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]