The most fatal disadvantage of zirconia ceramics is brittleness, which leads to low reliability of zirconia ceramic workpieces and also affects the scope of application. Therefore, we need to change the fracture toughness of zirconia ceramics and improve its reliability and service life, so that zirconia ceramics can become widely used new materials.

Be-Cu pottery products are widely recognized and favored by domestic and foreign customers because of their wide variety, excellent quality and favorable price.

The editor of Be-Cu Ceramics shared with you several methods on how to increase the toughness of zirconia ceramics, which is only for your reference and learning.

Phase transformation toughening means that the metastable tetragonal phase t-ZrO2 forms a monoclinic phase under the action of the stress field at the crack tip, resulting in volume expansion.

Thereby preventing crack propagation and achieving the effect of increasing toughness. In addition to these external conditions, it also has a great influence on the phase transformation and toughening of zirconia ceramics. If the phase transformation has great stress and volume changes, it is especially easy to cause product fracture.

Zirconium Ceramics Produce Phase Transformation Toughening

Particle toughening is to use particles as a toughening agent. In ZrO2 ceramic powder, the most suitable particle type, particle size and material must be selected to have a strong and tough effect. While toughening, there will also be changes in high temperature strength and high temperature creep properties.

The principle of fiber toughening is based on the crystal close to the crack tip. Because of the deformation, the surface of the crack has the ability to close, thereby offsetting the external stress at the crack tip and playing a toughening role. In addition to these, when the crack propagates, the columnar crystal also needs to overcome the friction when pulling out, so that the toughening effect can be achieved.

Because of the presence of columnar crystals in zirconia ceramics, when the zirconia ceramics fracture, the cracks will be deflected, thereby changing and increasing the crack path. Passivation cracks enhance the crack propagation resistance, which is self-toughening.

About the method of increasing the toughness of ceramics, I will share with you here. There are many ways to toughen ceramics, such as micro-crack toughening, composite toughening, nano-toughening and other methods. When the toughness of the zirconia ceramic workpiece is poor, the above methods may be used to solve it.Be-Cu ceramic zirconia ceramics have broad application prospects in the fields of electronics, aerospace, aviation and nuclear industries. The main products are sold all over the country and are deeply trusted by new and old customers. We wholeheartedly give back high-quality products and thoughtful services to new and old customers.

About China Advanced Ceramic CNC Machining Company - Be-Cu

Manufacturer of precision machined components. Ceramic cnc machining components include high dielectric strength, electrical & corrosion resistance, & non-porous & non-shrinking properties.Manufacturer of high temperature fabricated and machinable ceramics including alumina, glass-ceramic, alumino-silicate, boron nitride and zirconium phosphate. Adhesives, coatings and potting compounds to 3200 degrees F,Air firing services for ceramics up to 1650 degrees C also available. Products include insulators, guides, washers, tubes, blocks, & rods for thermal, electrical, corrosion exposure, structural, wear, & semi-conductor operations. Services include machining to tolerances of +/- .0001, ultrasonic core drilling, centerless grinding, milling, & ID & OD threading.Surface grinding, dicing, OD (outer dia.) grinding, ID (inner dia.) grinding, centerless grinding, hole drilling, jig grinding, lapping, honing & polishing service are also available. Diamond grinding with dimensional tolerances of 5 microns & surface finishes of 0.2 microns (8 micro-in.) can be performed.Blanket orders and AutoCAD files & other 3d files accepted.Contact us for your machining ceramic project!

-

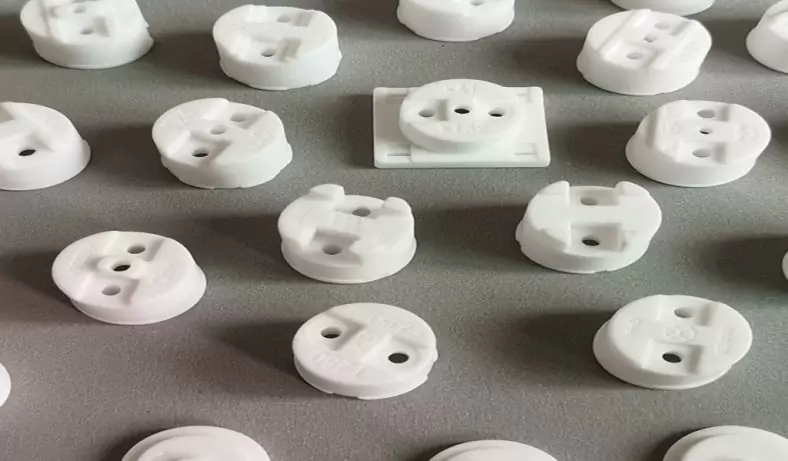

Metal Plating ZrO2 Zirconia Ceramic Parts

-

ZrO2 Structural Ceramic Semiconductor Parts

-

Alumina Ceramic Screw Type Parts

-

Cnc Machining Alumina Ceramic Screw Heating Pipe

-

Brushed Fishing Tackle Alumina Ceramic Accessories

-

Winding Machine Alumina Ceramic Wire Wheel

-

Insulation Device Microcrystalline Ceramic Multi-Slot Ceramic Column

-

99 Alumina Ceramic Spool Insulator Sleeve

-

The Alumina Ceramic Ring Of Textile Machine Thread Passing Wheel

-

Isostatic Pressure Insulation Alumina Ceramic Column