Zirconia Ceramic Parts

- NO.: ZrO2 Ceramic

- Color: Custom

- Surface Treatment: Custom

- Product Material: Ceramics

- Proofing Cycle:7 days(100000 pcs/M)

- Application: Cnc Machining

- machining Factory:Be-cu rapid prototyping companies

- Product Category: Non-Standard Parts

- Production Process: Cnc Milling

- Size: According To Customer’s Drawings

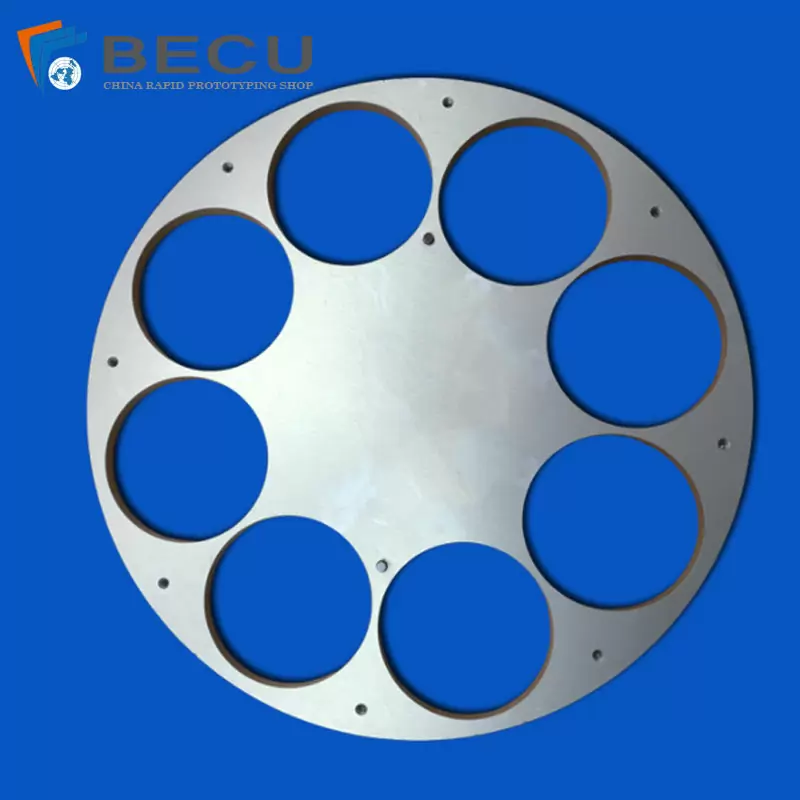

High-Quality Metal Plating ZrO2 Zirconia Ceramic Parts

Full service precision machining services for Metal Plating ZrO2 Zirconia Ceramic Parts. Capabilities are milling, turning, and Swiss screw machining. Provides prototypes and low to high volume production runs. Lead times are 2 to 3 weeks for prototypes and 4 to 6 weeks for production runs. Emergency and rush services are available.

The Advantages Of CNC Machining Metal Plating ZrO2 Zirconia Ceramic Parts

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Metal Plating ZrO2 Zirconia Ceramic Parts

| Material | ZrO2 Structural Ceramic |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Swiss Machining,Cnc Turning, Drilling, 5 Axis Cnc Machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Non Standard Parts |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

About China Advanced Ceramic CNC Machining Company - Be-Cu

Manufacturer of precision machined components. Ceramic cnc machining components include high dielectric strength, electrical & corrosion resistance, & non-porous & non-shrinking properties.Manufacturer of high temperature fabricated and machinable ceramics including alumina, glass-ceramic, alumino-silicate, boron nitride and zirconium phosphate. Adhesives, coatings and potting compounds to 3200 degrees F,Air firing services for ceramics up to 1650 degrees C also available. Products include insulators, guides, washers, tubes, blocks, & rods for thermal, electrical, corrosion exposure, structural, wear, & semi-conductor operations. Services include machining to tolerances of +/- .0001, ultrasonic core drilling, centerless grinding, milling, & ID & OD threading.Surface grinding, dicing, OD (outer dia.) grinding, ID (inner dia.) grinding, centerless grinding, hole drilling, jig grinding, lapping, honing & polishing service are also available. Diamond grinding with dimensional tolerances of 5 microns & surface finishes of 0.2 microns (8 micro-in.) can be performed.Blanket orders and AutoCAD files & other 3d files accepted.Contact us for your machining ceramic project!

-

Metal Plating ZrO2 Zirconia Ceramic Parts

-

ZrO2 Structural Ceramic Semiconductor Parts

-

Alumina Ceramic Screw Type Parts

-

Cnc Machining Alumina Ceramic Screw Heating Pipe

-

Brushed Fishing Tackle Alumina Ceramic Accessories

-

Winding Machine Alumina Ceramic Wire Wheel

-

Insulation Device Microcrystalline Ceramic Multi-Slot Ceramic Column

-

99 Alumina Ceramic Spool Insulator Sleeve

-

The Alumina Ceramic Ring Of Textile Machine Thread Passing Wheel

-

Isostatic Pressure Insulation Alumina Ceramic Column