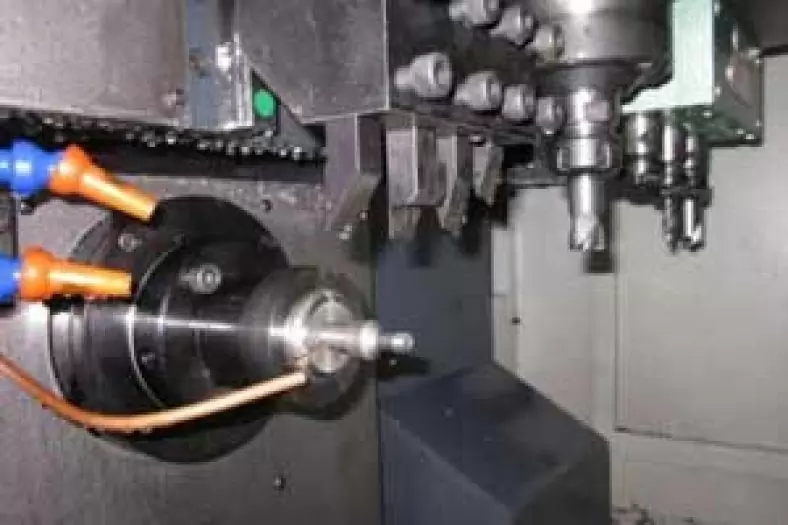

Machining process characteristics of CNC turning: turning plane,The turning plane mainly refers to the turning end plane including the step end face. The common methods are:

- use45For the turning plane of the partial knife, the larger back can be used to cut two, and the cutting is smooth.Smooth surface, both large and small planes can be turned

- use90Left offset tool feeds the turning plane from the outside to the center, which is suitable for the small end face of the machining center or the general stepped end face

- use90Left offset tool feeds the turning plane from the center to the outside, suitable for machining the end face with holes in the center or the general stepped end face

- Use the right offset knife to turn the plane, the strength of the cutter head is high, and it is suitable for turning large planes, especially large planes of castings and forgings

Turning Taper

The cone surface can be divided into inner cone surface and outer cone surface, which can be regarded as a special form of inner circle and outer circle respectively.

Turning Thread

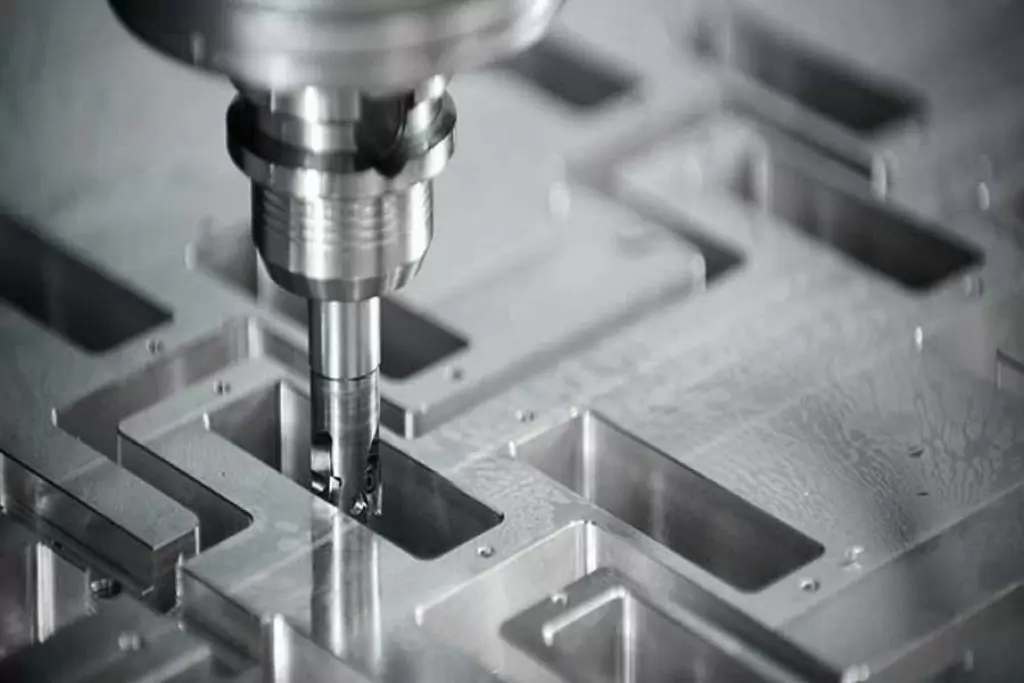

The main difference between the process route design of CNC machining and the conventional process route formulation of ordinary machine tool processing is that CNC machining may only be a few processes, rather than the entire process from blank to finished product. Generally speaking, the manufacturing process of a part is generally It is composed of CNC machining and conventional machining.

Since the CNC machining process is generally interspersed with the conventional machining process, the CNC machining and the conventional process must be taken into account in the process route design, and the two should be reasonably arranged to make It is in harmony with the whole process and is gentle

The CNC machining process cannot be completely separated from conventional machining. For more complex parts, more conventional machining processes may be interspersed in the CNC process flow, and the types of conventional processes involved will also be more, which requires CNC technicians.

To have good and comprehensive process knowledge, before implementing CNC machining, conventional cutting technology should be used to reduce the machining allowance as small as possible, which can not only shorten the time of CNC machining, reduce the processing cost, but also can Guarantee the quality of processing

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]