I believe that there are very few machining plants in the country that can process such products, let alone in Dongguan. In Dongguan, only Be-Cu ceramics can process zirconia ceramic side combs and there is a certain quality assurance.

Ceramic side combs , is a general term for ceramics made of metal carbides, nitrides, sulfides, silicides and borides. With the continuous development of science and technology, materials are required to have many characteristics. Ceramic side comb materials have achieved great development in recent decades, greatly promoting the progress of modern high-tech, playing a huge role in promoting the progress of human society, and making an indelible contribution to economic and national defense construction .

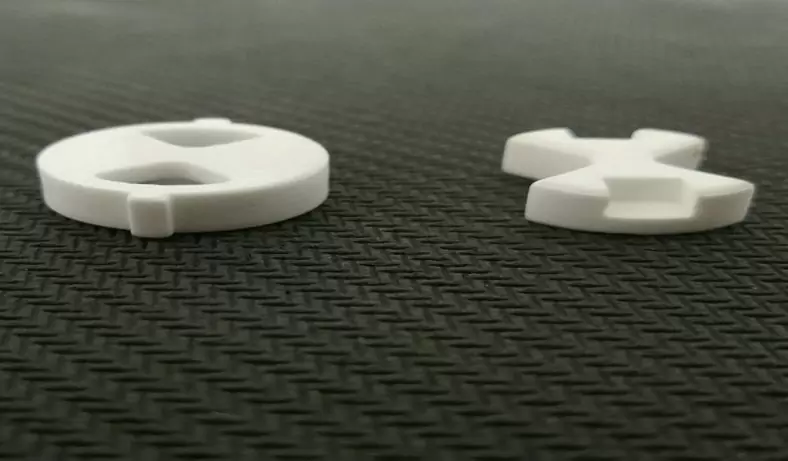

The Features Of Ceramic Side Combs

- There are few raw materials in nature, and artificial synthesis of raw materials is required.

- During the synthesis of raw materials and the sintering of ceramics, oxides are easily generated, and must be carried out in a protective atmosphere (Ar, N2).

- The side comb of zirconia ceramics is generally a covalent bond with strong bond energy, so it is difficult to melt or sinter.

Ceramic Side Combs vs Oxide Ceramics

The difference between ceramic side combs and oxide ceramics is that the atoms of ceramic side combs are mainly bonded together by covalent bonds, so they have high hardness, modulus, and creep resistance, and can maintain these properties to a large extent. To the high temperature state, this is unmatched by oxide ceramics.

The disadvantage is that the sintering of ceramic side combs is generally difficult, and high-density products must be obtained at extremely high temperatures (1500~2500 ° C) with sintering aids, and sometimes hot-pressing sintering is required to achieve the desired density (>95 ℃). %), which leads to the fact that the production cost of ceramic side combs is generally higher than that of oxide ceramics.

Some of these ceramic materials, such as Si3N4, SiC, etc., may be used in high-efficiency engines and gas turbines, which has attracted great interest of scientists because they are closely related to the urgent energy problems to be solved in sophisticated industrial countries. But as new materials, these ceramic side combs are also a material with a special appeal.

Among non-oxides, carbides and nitrides attract attention as structural materials because most of the atomic bonds of these materials are covalent bonds, so they have strong deformation resistance at high temperatures.

Different from oxides, zirconia ceramics rarely exist in nature. It needs artificial synthesis of raw materials, and then made products according to the ceramic process. During feedstock synthesis, contact with oxygen must be avoided, otherwise oxides will be produced first rather than nitrides or carbides as expected. This is analyzed from the standard thermodynamic free enthalpy of formation ΔG0, and it can be clearly seen that the larger the negative value of ΔG0.

The greater the affinity of the element for O2, the more stable the compound. The standard production free enthalpies of carbides, nitrides and sulfides are generally greater than the corresponding oxides ΔG0, indicating that the resulting oxides are more stable.

Therefore, the synthesis and sintering of these zirconia ceramic raw materials must be carried out in a protective gas (N2, inert gas) to avoid the formation of oxides and affect the high temperature performance of the material.Be-Cu Ceramics is specialized in machining this type of composite material and has extensive experience. There is a certain quality assurance.

About China Advanced Ceramic CNC Machining Company - Be-Cu

Manufacturer of precision machined components. Ceramic cnc machining components include high dielectric strength, electrical & corrosion resistance, & non-porous & non-shrinking properties.Manufacturer of high temperature fabricated and machinable ceramics including alumina, glass-ceramic, alumino-silicate, boron nitride and zirconium phosphate. Adhesives, coatings and potting compounds to 3200 degrees F,Air firing services for ceramics up to 1650 degrees C also available. Products include insulators, guides, washers, tubes, blocks, & rods for thermal, electrical, corrosion exposure, structural, wear, & semi-conductor operations. Services include machining to tolerances of +/- .0001, ultrasonic core drilling, centerless grinding, milling, & ID & OD threading.Surface grinding, dicing, OD (outer dia.) grinding, ID (inner dia.) grinding, centerless grinding, hole drilling, jig grinding, lapping, honing & polishing service are also available. Diamond grinding with dimensional tolerances of 5 microns & surface finishes of 0.2 microns (8 micro-in.) can be performed.Blanket orders and AutoCAD files & other 3d files accepted.Contact us for your machining ceramic project!

-

Metal Plating ZrO2 Zirconia Ceramic Parts

-

ZrO2 Structural Ceramic Semiconductor Parts

-

Alumina Ceramic Screw Type Parts

-

Cnc Machining Alumina Ceramic Screw Heating Pipe

-

Brushed Fishing Tackle Alumina Ceramic Accessories

-

Winding Machine Alumina Ceramic Wire Wheel

-

Insulation Device Microcrystalline Ceramic Multi-Slot Ceramic Column

-

99 Alumina Ceramic Spool Insulator Sleeve

-

The Alumina Ceramic Ring Of Textile Machine Thread Passing Wheel

-

Isostatic Pressure Insulation Alumina Ceramic Column