In the realm of medical advancements, the marriage of technology and healthcare continues to propel innovation. One such groundbreaking technological advancement that has transformed the landscape of medical device manufacturing is micro laser cutting. The fusion of precision engineering and laser technology has ushered in a new era of creating intricate and precise medical components, empowering the development of state-of-the-art devices that save lives and improve patient care.

Introduction to Micro Laser Cutting in Medicine

Micro laser cutting involves the use of highly focused laser beams to accurately cut and shape materials with exceptional precision. This technique has found its niche in the medical sector, where the demand for intricate, miniaturized components for medical devices is ever-increasing. The ability to fabricate tiny, complex geometries with micron-level accuracy has opened doors to innovative solutions in various medical applications.

Applications in Medical Device Manufacturing

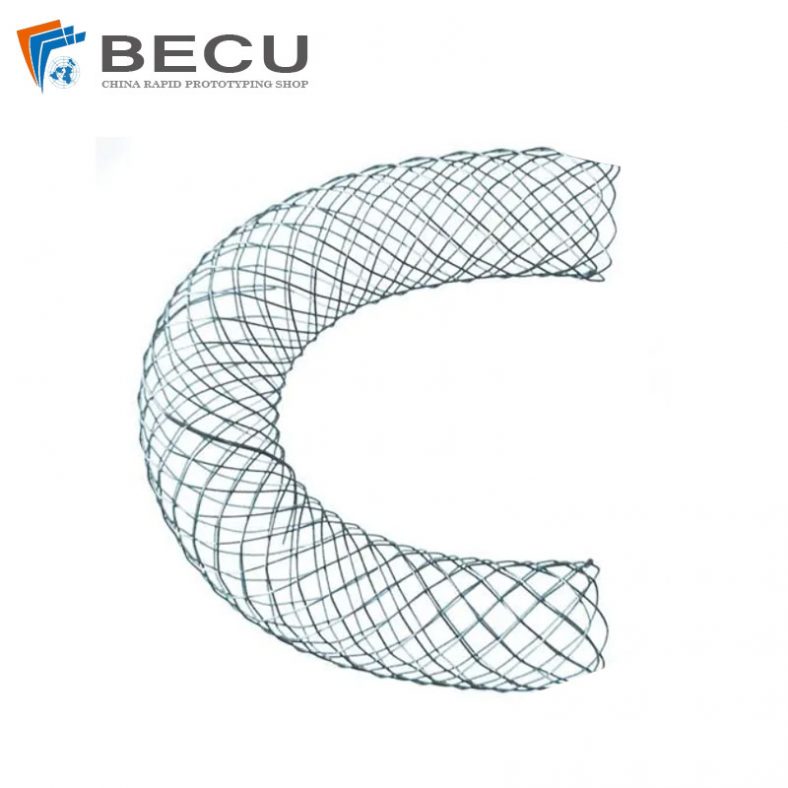

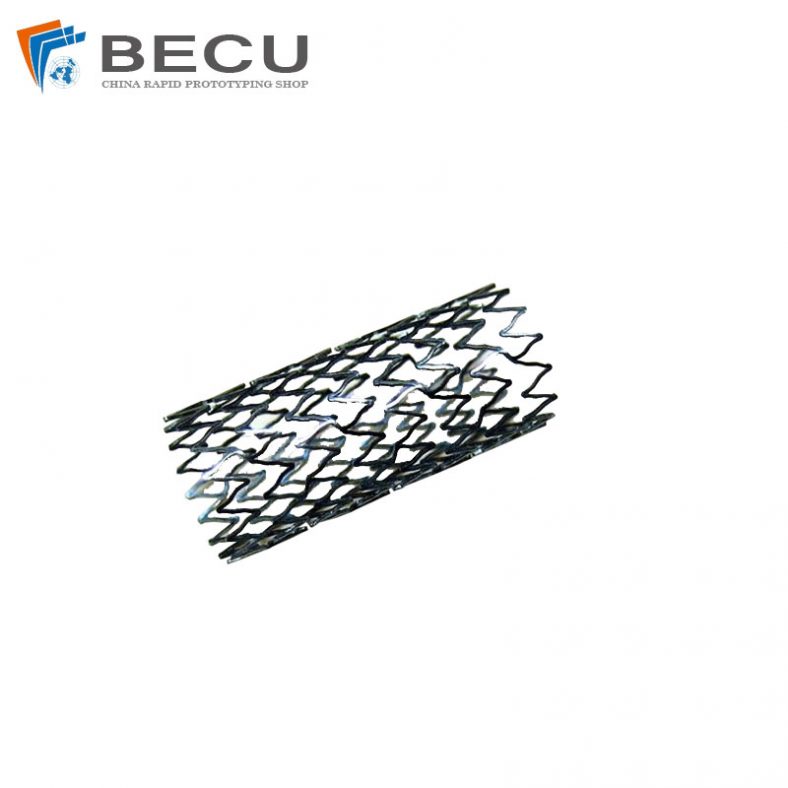

The impact of micro laser cutting reverberates across a multitude of medical specialties. In the realm of cardiovascular medicine, the production of stents—small mesh tubes used to treat narrowed or weakened arteries—has significantly benefitted from this technology. The precision offered by micro laser cutting enables the creation of intricate patterns on these stents, optimizing their performance and enhancing patient outcomes.

Moreover, the field of minimally invasive surgery has undergone a revolution with the aid of micro laser-cut components. Tools and instruments used in laparoscopic and endoscopic procedures are now designed with exceptional precision, allowing for smaller incisions, reduced trauma, and faster patient recovery times.

Additionally, micro laser cutting has played a pivotal role in the manufacturing of diagnostic devices. Microfluidic chips, used for various diagnostic tests, require intricate channels and precise structures. Laser cutting technology facilitates the creation of these minute details, enhancing the sensitivity and accuracy of diagnostic tools.

Advantages and Innovations

The advantages offered by micro laser cutting are manifold. The unparalleled precision allows for the production of intricate and complex designs that were once deemed unachievable. The ability to work with a wide array of materials, including metals, polymers, and ceramics, further expands the scope of possibilities in medical device manufacturing.

Furthermore, the non-contact nature of laser cutting minimizes material distortion and damage, ensuring high-quality end products. The speed and efficiency of the process also contribute to cost-effectiveness in mass production, making it a viable option for the medical industry.

Innovation in this field continues to evolve, with advancements in laser technology leading to even finer resolutions and faster cutting speeds. Integration of robotics and automation further enhances the precision and consistency of the manufacturing process, setting new standards for quality and reliability in medical device fabrication.

Challenges and Future Perspectives

While micro laser cutting has revolutionized medical device manufacturing, challenges persist. The need for continuous refinement of laser technology to achieve even greater precision without compromising production speeds remains a focus for researchers and engineers.

Additionally, ensuring the biocompatibility and sterilizability of laser-cut medical components is crucial. Research endeavors are directed toward developing materials and surface treatments that meet stringent medical standards, ensuring the safety and efficacy of devices manufactured using this technique.

Looking ahead, the future of micro laser cutting in medicine appears promising. With ongoing advancements in laser technology, coupled with interdisciplinary collaborations between engineers, material scientists, and medical professionals, the potential for creating increasingly sophisticated and tailored medical devices is boundless.

Conclusion

Micro laser cutting stands at the forefront of revolutionizing medical device manufacturing, offering unparalleled precision and versatility. Its applications span across various medical specialties, empowering the creation of innovative devices that improve patient care and outcomes. As technology continues to evolve, the fusion of laser precision and medical ingenuity holds the promise of shaping a future where intricate and customized medical solutions become the norm, furthering the boundaries of healthcare possibilities.

The Detail Of BE-CU Laser Cutting Company

BE-CU.COM Laser Cutting provides services to a wide network of industries and markets. BE-CU is uniquely positioned to Laser Cut, Laser Engrave, Precision CNC Machine and Precision Finish Grind parts and components.We use large format industrial laser cutting machines that are extremely precise with up to .001” tolerance. Not only we cut and engrave your project, we are ready to answer any questions you may have about the process and give you expert advice.

So, reach out even if you’re unsure of your specific need or if you think you may require a different type of manufacturing service(as laser cutting medical parts). Laser cutting service by BE-CU makes ordering your parts simple. Just upload your CAD files onto the platform for an instant price and lead time. Our mission is to save engineers’ time for value-adding activities.

-

Etching LED EMC Packaging Bracket

-

Etching Low Resistivity Copper 110 Contact Rings

-

Laser Cut Nitinol Stent For Bile Duct

-

Stents For Carrying Valves And Venous Valve Replacement Devices

-

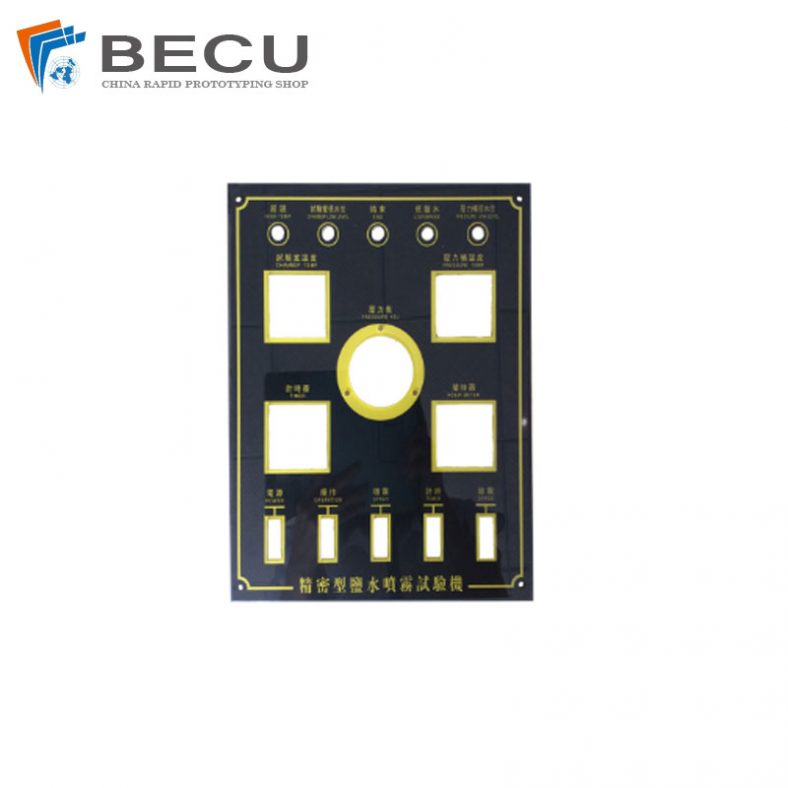

Laser Cutting PC Anti-Static Membrane Switch

-

Precision Engraving Special-Shaped Natural Color PEEK Parts

-

Acrylic Laser Cut Signs

-

Acrylic Laser Cut Earrings