Macor has a high service temperature (800°C continuous to 1,000°C peak). It has low thermal conductivity and is a useful high temperature insulator as well as an excellent electrical insulator. Macor has no pores and when baked properly, will not outgas. It is strong and rigid, and unlike high temperature plastics, does not creep or deform. Macor is also radiation resistant.

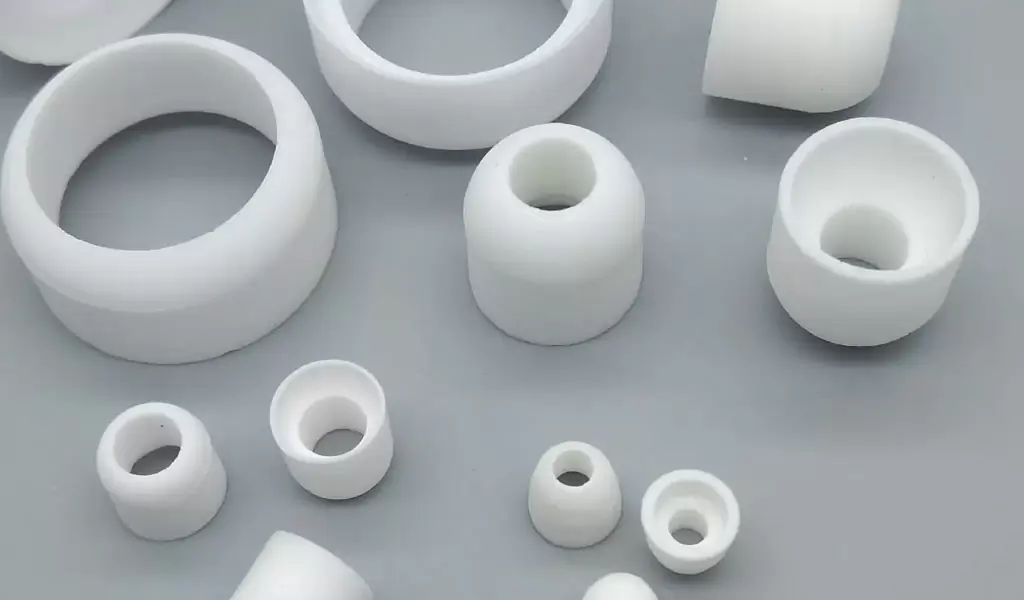

Macor is pure white and can be highly polished. It can be thick or thin film metallization, brazing and epoxy bonding. Another major advantage of this unique material is that the components are economical to manufacture even in small quantities.

The Application Field Of Macor Ceramics

Macor ceramics are used for insulators and coil carriers in high and constant vacuum environments, as well as for electrodes and dielectric carriers in the electrical industry.Main performance:

- No porosity, no outgassing

- Low thermal conductivity

- Outstanding electrical performance

- Continuous operating temperature: 800°C

- No need to sinter

- Can be coated with a variety of materials

Machining speed and coolant are decisive factors for the successful machining of Macor machinable glass ceramics.

Macor machinable glass-ceramics consist of a glass matrix containing mica crystals. Its microstructure, consisting of 55 % fluorophlogopite mica and 45 % borosilicate glass, can be machined into complex shapes with conventional metalworking tools. Below you can find some information on the composition of Macor’s machinable glass ceramics.

The Attributes Of Macor Ceramics

Macor machinable glass-ceramic is an excellent technical material with huge advantages in machining. Macor machinable glass ceramic is a white, non-wetting, odorless, non-porous and non-venting material.

It is very suitable for machining. Macor machinable glass ceramics are produced to very tight tolerances (+/- 0.01 mm, surface finish < 0.5 microns, polish < 0.013 microns) for complex shapes. Macor machinable glass-ceramics are homogeneous and stable at 800 °C, peaking at 1000 °C under no load. Unlike ductile materials, it does not creep or deform.

Its coefficient of thermal expansion is equal to that of most metal and glass solders. As an electrical insulator – especially at high temperatures – the material excels at high voltages and a wide frequency spectrum.

The Advantage Of Macor Ceramics

Ease of machining, high temperature resistance, low thermal conductivity, keeping close tolerances, electrical insulator, non-porous, non-outgassing, strong and hard, highly polishable, brazable in many materials, radiation resistant, lead free, constant and ultra High vacuum environment, laser technology, semiconductor/electronics, aerospace, chemical industry, automotive industry, military, nuclear industry…etc.

Macor’s machinable glass ceramics unique material combines the performance of technical ceramics with the versatility of advanced polymers, providing value-added opportunities for many industries. Macor machinable glass ceramics are an excellent engineered solution to meet most technical material needs quickly, accurately and economically.

Pintejin ceramics machining Macor ceramics has strong technical force and strong development ability. It can produce and process various types of ceramic special-shaped parts according to customer drawings, especially the machining of glass-ceramic ceramics macor. The product has high dimensional accuracy and stable performance. If you have precision machining requirements for glass-ceramic ceramics, please contact us: [email protected]

About China Advanced Ceramic CNC Machining Company – Be-Cu

Manufacturer of precision machined components. Ceramic cnc machining components include high dielectric strength, electrical & corrosion resistance, & non-porous & non-shrinking properties.Manufacturer of high temperature fabricated and machinable ceramics including alumina, glass-ceramic, alumino-silicate, boron nitride and zirconium phosphate. Adhesives, coatings and potting compounds to 3200 degrees F,Air firing services for ceramics up to 1650 degrees C also available. Products include insulators, guides, washers, tubes, blocks, & rods for thermal, electrical, corrosion exposure, structural, wear, & semi-conductor operations. Services include machining to tolerances of +/- .0001, ultrasonic core drilling, centerless grinding, milling, & ID & OD threading.Surface grinding, dicing, OD (outer dia.) grinding, ID (inner dia.) grinding, centerless grinding, hole drilling, jig grinding, lapping, honing & polishing service are also available. Diamond grinding with dimensional tolerances of 5 microns & surface finishes of 0.2 microns (8 micro-in.) can be performed.Blanket orders and AutoCAD files & other 3d files accepted.Contact us for your machining ceramic project!

-

Metal Plating ZrO2 Zirconia Ceramic Parts

-

ZrO2 Structural Ceramic Semiconductor Parts

-

Alumina Ceramic Screw Type Parts

-

Cnc Machining Alumina Ceramic Screw Heating Pipe

-

Brushed Fishing Tackle Alumina Ceramic Accessories

-

Winding Machine Alumina Ceramic Wire Wheel

-

Insulation Device Microcrystalline Ceramic Multi-Slot Ceramic Column

-

99 Alumina Ceramic Spool Insulator Sleeve

-

The Alumina Ceramic Ring Of Textile Machine Thread Passing Wheel

-

Isostatic Pressure Insulation Alumina Ceramic Column