What Is An Aluminum Nitride Ceramic Substrate?

Simply put, aluminum nitride ceramic (Aluminum Nitride Ceramic) is a ceramic with aluminum nitride (AIN) as the main crystal phase. It is made into a substrate. Imagine the bottom layer inside the circuit board. The base is it! Aluminum nitride ceramics also have a certain space for development in the market now. Aluminum nitride ceramics can be applied to the aerospace field and satellite brackets, as well as rockets, bulletproofs, and armor. Pintejin Ceramics is a professional manufacturer of special ceramics and machining of special ceramics. The company has its own professional and technical team, and has established a close industry-university-research cooperation relationship with a number of scientific research institutions and colleges and universities. Pintejin Ceramics has been committed to the technology development, product design and manufacturing and on-site construction of special ceramic materials all the year round, ensuring to provide users with high-quality special ceramic anti-corrosion materials and engineering services. Contact Pintejin Ceramics Tel: +86 769 82886112.

1. Aluminum Nitride

(AlN) ceramic substrate is a new type of substrate material with excellent electrical, mechanical and thermal properties, high thermal conductivity (about 320W/m?K) and low dielectric constant. (about 8.8), has a thermal expansion coefficient (4.5×10-6°C) matching silicon Si (3.5~4×10-6°C), high resistivity (>1014Ω?cm), high breakdown field strength ( 1.4×107V/cm), low specific gravity (theoretical density 3.26g/cm3), high mechanical strength (flexural strength 300-400MPa), non-toxic, it is an ideal large-scale integrated circuit heat dissipation substrate and packaging material. .

In addition, the aluminum nitride ceramic substrate does not contain organic components, and the copper layer does not contain an oxide layer. It has excellent corrosion resistance to molten metal, and has a long service life. It can be used for a long time in a reducing atmosphere. The application prospect in aerospace, communication, microelectronics and other fields is very broad.

2. However, The Difficulty Of Making

Since AlN is a compound mainly bonded by covalent bonds, its self-diffusion coefficient is small, and it is difficult to sinter densely, so the sintering process of AlN is a difficulty in the process of making substrate materials. The sintering of aluminum nitride ceramics mainly needs to pay attention to the following points. The first is the heating rate, the sintering temperature and the holding time. The sintering temperature of these high-performance ceramics is generally 1800~1900 ° C. Secondly, a suitable protective atmosphere should be selected to prevent AlN oxidation and sintering. The process must be isolated from oxygen and carried out in an atmospheric environment, because the presence of oxygen will increase the thermal resistance and reduce thermal conductivity. Finally, make sure that the sintering equipment has good temperature uniformity.

3. Excellent Sintering Furnace Appeared!

Carbolite Gero (Carbolite Gero) has a very wide range of customers and mature process technology in the sintering of aluminum nitride ceramics at home and abroad, and can provide chamber furnaces (HTK series) and bell furnaces (HBO series).

The radiation protection and heat insulation shielding material of the furnace and the heating element are the same material, and there is no fiber insulation material, so it can achieve high vacuum degree and a pure atmosphere environment (the fiber material will have pores), which ensures the safety of the sintering process at high temperatures . Carbolite? Gero also guarantees a high-purity atmosphere (>6N) and a high degree of vacuum. Certified safe management of hydrogen partial pressure and reducing or toxic gases upon request. Data logging for quality control. In addition, reasonable distribution of heating elements, three-zone temperature control heating technology and atmosphere preheating ensure good temperature uniformity of the equipment. In addition, the furnace body can be automatically raised and lowered, and the process is very stable, ensuring that the sample is not affected by vibration.

For AlN ceramic sintering applications, Carbolite Gero offers high temperature atmosphere furnaces with a complete hydrogen system and equipped with a two stage rotary vane pump. Metal tungsten insulation and tungsten heating elements. In order to improve the temperature uniformity of the use area, three-zone heating is adopted. The system can use 100% pure hydrogen or a mixture of hydrogen and nitrogen in the range of room temperature to 2200°C. Because of the application of hydrogen, the furnace has added a complete set of safety devices.

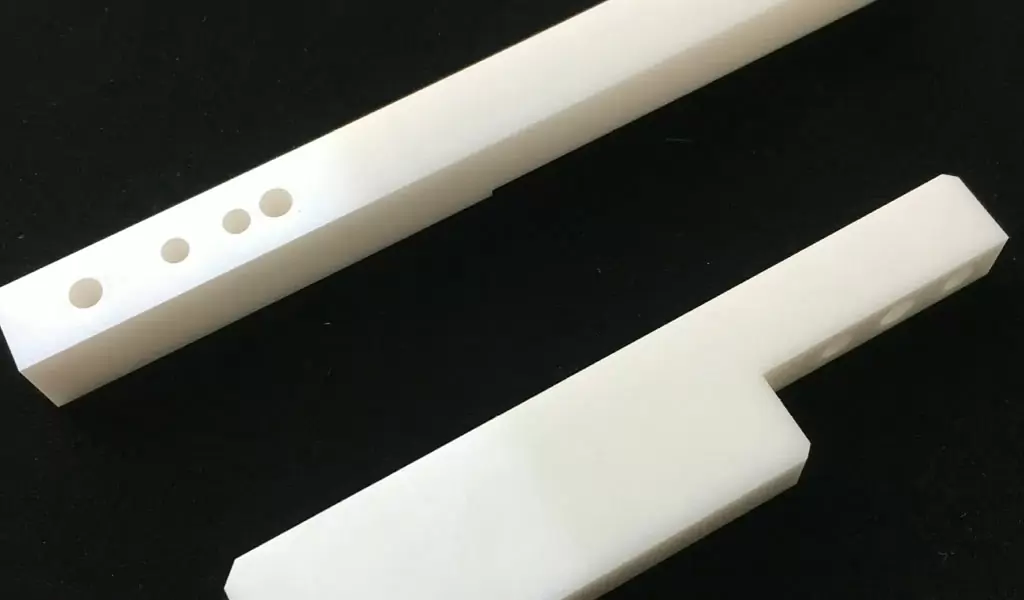

About China Advanced Ceramic CNC Machining Company – Be-Cu

Manufacturer of precision machined components. Ceramic cnc machining components include high dielectric strength, electrical & corrosion resistance, & non-porous & non-shrinking properties.Manufacturer of high temperature fabricated and machinable ceramics including alumina, glass-ceramic, alumino-silicate, boron nitride and zirconium phosphate. Adhesives, coatings and potting compounds to 3200 degrees F,Air firing services for ceramics up to 1650 degrees C also available. Products include insulators, guides, washers, tubes, blocks, & rods for thermal, electrical, corrosion exposure, structural, wear, & semi-conductor operations. Services include machining to tolerances of +/- .0001, ultrasonic core drilling, centerless grinding, milling, & ID & OD threading.Surface grinding, dicing, OD (outer dia.) grinding, ID (inner dia.) grinding, centerless grinding, hole drilling, jig grinding, lapping, honing & polishing service are also available. Diamond grinding with dimensional tolerances of 5 microns & surface finishes of 0.2 microns (8 micro-in.) can be performed.Blanket orders and AutoCAD files & other 3d files accepted.Contact us for your machining ceramic project!

-

Metal Plating ZrO2 Zirconia Ceramic Parts

-

ZrO2 Structural Ceramic Semiconductor Parts

-

Alumina Ceramic Screw Type Parts

-

Cnc Machining Alumina Ceramic Screw Heating Pipe

-

Brushed Fishing Tackle Alumina Ceramic Accessories

-

Winding Machine Alumina Ceramic Wire Wheel

-

Insulation Device Microcrystalline Ceramic Multi-Slot Ceramic Column

-

99 Alumina Ceramic Spool Insulator Sleeve

-

The Alumina Ceramic Ring Of Textile Machine Thread Passing Wheel

-

Isostatic Pressure Insulation Alumina Ceramic Column