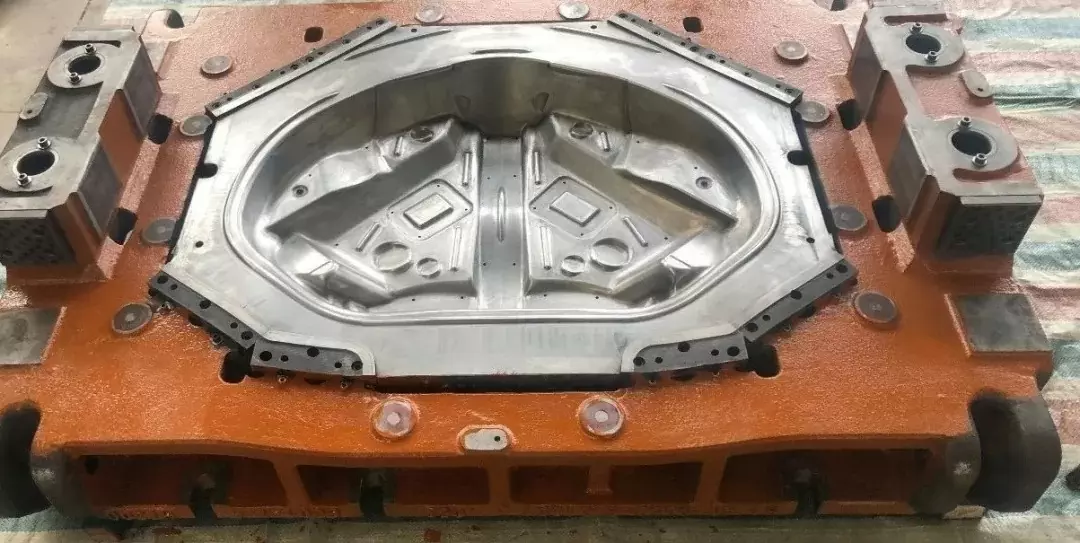

Many people are discouraged by the drawing die, because the drawing die not only needs to consider many factors in the design, but more importantly, it is often not possible to form at one time during the mold trial, and it needs to be repaired many times to achieve the desired result. Therefore, the continuous accumulation of experience in practice is of great benefit to the design of the drawing die.

1.Material:

SPCC-SD Deep Drawing Steel

Good material is half the battle, and when it comes to stretching, it must not be ignored. The cold-rolled thin steel sheets for drawing mainly include 08Al, 08, 08F, 10, 15, and 20 steels, of which the largest amount is 08 steel, which is divided into boiling steel and killed steel. The boiling steel has low price and good surface quality, but The segregation is more serious, and there is a tendency of “strain aging”. It is not suitable for parts with strict requirements on stamping performance and appearance. Killed steel is better, with uniform performance but high price. The representative grade is aluminum killed steel 08Al. Foreign steel has used Japanese SPCC-SD deep drawing steel, and its tensile properties are better than 08Al.

Experience 1: When the customer’s requirements for materials are not very strict, and the repeated mold test fails to meet the requirements, you can try another material.

2. Determination of blank size:

Confirmation of blank size

The diameter of the blank of the rotating body drawing part with a simple shape is not thinned. Although the thickness of the material changes, it is basically very close to the original thickness. The upper trimming allowance) is equal to the principle of calculation. However, the shape and process of the stretched parts are often complicated, and sometimes they are thinned and stretched. Although there are many 3D softwares that can calculate the unfolded material, the accuracy cannot meet the requirements 100%.

Solution: sample.

A product has to go through multiple processes, and the first process is generally the blanking process. First of all, it is necessary to carry out the calculation of the unrolling material, and have a general understanding of the shape and size of the blank in order to determine the overall size of the blanking die. Do not process the punch and concave dimensions of the blanking die after the die design is completed. First, the blank is processed by wire cutting (if the blank is larger, it can be milled by a milling machine and then clamped), and after repeated experiments in the subsequent stretching process, the size of the blank is finally determined, and then the convex and concave dies of the blanking die are processed.

Experience 2: Inverting the process, first try the drawing die, and then process the blanking edge size of the blank, which is twice the result with half the effort.

3. Tensile coefficient mold

The stretching coefficient is one of the main process parameters in the calculation of the stretching process, and it is usually used to determine the order and times of stretching. There are many factors that affect the stretching coefficient m, including material properties, relative thickness of materials, stretching method (referring to whether there is a blank holder), stretching times, stretching speed, punch and concave die fillet radius, lubrication, etc. The calculation and selection principles of the tensile coefficient m are the key points introduced in various stamping manuals. There are many methods such as calculation, table look-up, calculation, etc. It is auspicious and auspicious. I also choose according to the book, there is nothing new, please read the book .

Experience 3: The relative thickness of the material, the stretching method (referring to whether there is a blank holder or not), and the number of stretching are not easy to adjust when repairing the mold, so be careful!! It is best to find a colleague when choosing the stretching coefficient m. again.

4. Apply lubricating oil on the die, or put a film bag on the thin plate.

Experience 4: When encountering tensile cracks, apply lubricating oil on the die (not on the punch), and cover the workpiece with a plastic film of 0.013-0.018mm on the side of the die.

5. Workpiece heat treatment

Heat treatment workshop

During the stretching process, due to cold plastic deformation of the workpiece, cold work hardening occurs, which reduces its plasticity and increases its deformation resistance and hardness. In addition, the mold design is unreasonable, and intermediate annealing is required to soften the metal and restore its plasticity.

Note: Intermediate annealing is not necessary in general processes. After all, to increase the cost, it is necessary to choose between increasing processes and increasing annealing. Use with caution! Annealing generally adopts low temperature annealing, that is, recrystallization annealing. There are two things to be aware of when annealing: decarburization and oxidation. Here we mainly talk about oxidation. After the workpiece is oxidized, there is oxide skin, which has two disadvantages: the effective thickness of the workpiece is thinned and the mold wear is increased. When the company’s conditions are not available, ordinary annealing is generally used. In order to reduce the generation of oxide scale, the furnace should be filled as much as possible during annealing. There are also some methods:

1. When the workpiece is few, it can be mixed with other workpieces (premise: the annealing process parameters should be basically the same)

2. Put the workpiece in the iron box and weld it in the furnace before loading it in the furnace. In order to eliminate the oxide scale, pickling treatment should be carried out according to the situation after annealing. When the company conditions are available, nitrogen furnace annealing, that is, bright annealing, can be used. If you don’t look closely, it is almost the same color as before annealing.

Experience 5: When dealing with metals with strong cold work hardening or when there is no other way to crack in the mold test, increase the intermediate annealing process.

6. Additional points:

1. The dimensions on the product drawing should be marked on one side as much as possible, so that it is clear whether to guarantee the external size or the internal cavity size, and the internal and external dimensions cannot be marked at the same time. If the drawings provided by others have such problems, they should communicate with them. If they can be unified, they should be unified. If they cannot be unified, they should know the assembly relationship between the workpiece and other parts.

2. For the last process, the size of the workpiece is outside, and the die is mainly used, and the gap is obtained by reducing the size of the punch; the size of the workpiece is included, and the size of the punch is mainly obtained, and the gap is obtained by increasing the size of the punch;

3. The fillet radius of the convex and concave die should be designed with a small allowable value as much as possible, which will bring convenience to the subsequent die repair.

4. When judging the cause of the cracking of the workpiece, you can refer to: the cracks caused by poor material quality are mostly serrated or irregular in shape, and the cracks caused by the process and mold are generally neat.

5. “More wrinkles, less cracks”, according to this principle to adjust the flow of the material, the methods include adjusting the pressure of the blank holder, increasing the drawing bead, trimming the radius of the convex and concave die, and cutting the process port on the workpiece.

6. In order to ensure wear resistance and prevent tensile scratches, the convex and concave die and the blank holder must be quenched, and can be plated with hard chrome if necessary.

Sheet fabrication services for mild steel, high strength low alloy (HSLA) steel, cold/hot rolled steel, galvanized steel, stainless steel, aluminum, copper and brass. Capable of fabricating parts up to 12 ft. length and +/-0.001 in. tolerance. Various capabilities include contract manufacturing,custom stamping,edge rolling, forming,top laser cutting, roll bending and welding. Finishing and secondary services such as hardware installation, tapping, deburring, cleaning, heat treating, plating, anodizing and painting available. Sheet Metal Prototype and low to high volume production runs offered. Suitable for commercial/residential architectural, aluminum brake shape parts, wall panel systems, brackets, general flashings, rails, call button plates and ship building component parts.