Metal laser cutting machine is a new type of cutting equipment widely used in industrial production. It gradually eliminates traditional machine tool cutting. Laser cutter is composed of laser cutting machine, cutting head and other components. One of the conventional lasers includes three parts: Working substance, pump source and optical resonator.

Fundamentals of Laser Technology

Laser cutters have revolutionized various industries with their precision and versatility, enabling intricate designs and high-speed manufacturing processes. Central to the operation of these machines is the laser itself, a complex device that generates a powerful, coherent beam of light capable of cutting through various materials with pinpoint accuracy. This article delves into the fundamental components of lasers used in laser cutters, exploring the science behind their functionality and the engineering that makes them indispensable tools in modern manufacturing.

1.1 What is a Laser?

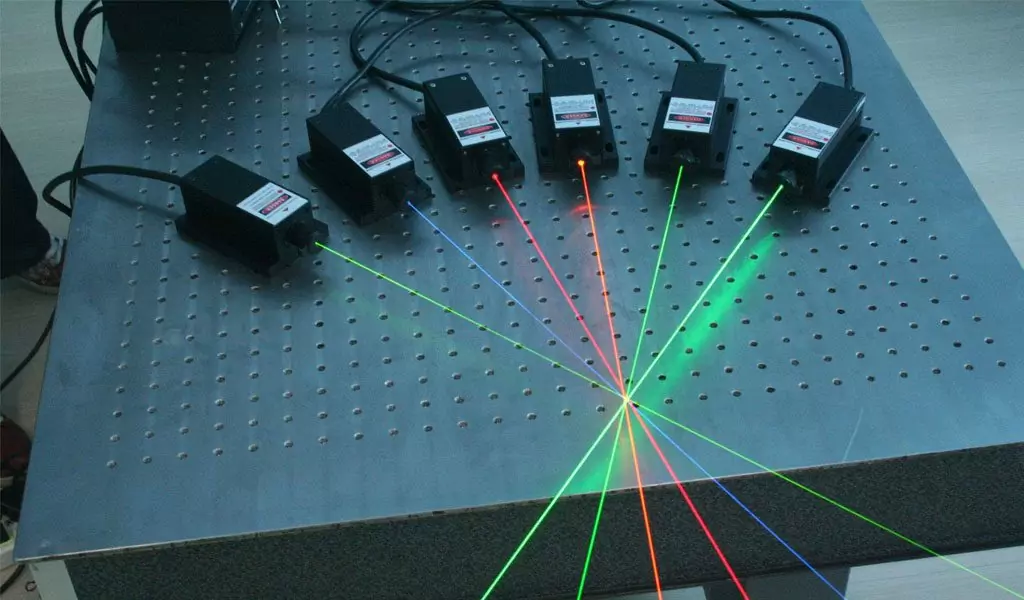

The term “laser” stands for Light Amplification by Stimulated Emission of Radiation. A laser produces a narrow, highly concentrated beam of light that is both monochromatic (single color or wavelength) and coherent (all the light waves are in phase with each other).

1.2 Basic Principles of Laser Operation

Lasers operate based on the principles of stimulated emission and population inversion. In a laser, atoms or molecules are excited to higher energy states by an external energy source. When these excited particles return to their lower energy states, they emit photons. Under the right conditions, these photons stimulate the emission of more photons from other excited particles, leading to a chain reaction that amplifies the light.

1.3 Historical Development

The concept of lasers was first theorized by Albert Einstein in 1917 through his work on stimulated emission. The first functional laser was developed by Theodore H. Maiman in 1960, using a ruby crystal. Since then, laser technology has evolved significantly, leading to the development of various types of lasers used in different applications, including metal etching and laser cutting.

Working Substances

The working substance is the material basis for laser generation, the core part of the laser, and the material system used to achieve particle number inversion and generate stimulated radiation. There are usually two ways to classify the working substances: one is based on the existence form of the working substances, and the other substances can be divided into gases, homogenous bodies, liquids and semiconductors, etc.; the other is to analyze the metal laser cutting process of generating laser light according to the rate equation theory. The applicable energy level structure can be divided into three-level system, four-level system and so on.

The particles that generate the laser light in a gas laser are gas molecules or atoms. In solid-state lasers, crystals or glass doped with a small amount of transition metal ions or rare earth ions are used as working substances, and doped ions are used as working particles. and glass as the matrix material. The working substance of a liquid laser is a liquid, and the common one is a dye laser. The working substance is a solution composed of a dye dissolved in a solvent, the dye molecules are working particles, and the solvent is equivalent to the matrix.The working material of semiconductor lasers is semiconductors. Although the semiconductors are solids, the formation mechanism of the population inversion of semiconductor lasers is essentially different from that of ordinary solid-state lasers, so the two are generally not classified into one category.

Types of Lasers Used in Laser Cutters

2.1 CO2 Lasers

CO2 lasers are among the most common types of lasers used in laser cutters. They operate at a wavelength of around 10.6 micrometers and are particularly effective for cutting, engraving, and boring non-metallic materials like wood, acrylic, and textiles.

2.2 Fiber Lasers

Fiber lasers are known for their efficiency and high power output. They utilize optical fibers doped with rare earth elements like erbium, ytterbium, or neodymium. Fiber lasers are typically used for cutting metals due to their high power density and precise control.

2.3 Nd:YAG Lasers

Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) lasers operate at a wavelength of 1.064 micrometers. They are versatile and can cut a variety of materials, including metals,plastic and mica sheet laser cutting. They are particularly useful in applications requiring deep penetration and high precision.

2.4 Diode Lasers

Diode lasers are compact, efficient, and versatile. They are commonly used in lower-power laser cutting applications and are suitable for cutting thin materials or performing intricate engraving work.

Pump Source

A pump source (excitation source) is a device that provides energy for population inversion. According to the energy form used in excitation, the pumping methods include discharge excitation, optical excitation, thermal energy excitation, chemical energy excitation and nuclear energy excitation.

Gas discharge excitation is a commonly used excitation method for gas lasers. Its excitation mechanism is to use the ionization and conduction of gas molecules under high voltage. After the electron energy transitions to a high energy level, a population inversion is formed; in addition, the high-speed electrons generated by the electron gun can also be used to pump the working substance to make the transition to a high energy level, which is called electron beam excitation; semiconductor laser clamps the current Achieving pumping is called injection pumping.

Photoexcitation is the use of light to irradiate a working substance, and the working substance absorbs light energy to generate a population inversion. The light source of light excitation can be a high-efficiency, high-intensity light-emitting lamp, and solar energy can be turned into a laser. Solid lasers and liquid lasers commonly use optical excitation methods.

Thermal excitation is to use high temperature heating to increase the number of gas particles on the high energy level, and then suddenly reduce the gas temperature, because the thermal relaxation time of high and low energy levels is different, the relaxation time of low energy levels is short, and the relaxation time of high energy levels is long, so as to achieve high and low energy levels. Population inversion between energy levels.

The chemical energy incentive utilizes the chemical energy released during the chemical reaction to pump the particles to the upper energy level, establishing a population inversion. Unlike the above-mentioned discharge excitation, optical excitation and thermal excitation, chemical excitation requires external energy, so in some special places where there is no power supply, chemical lasers use their specialties.

Optical Resonator

Optical resonator (referred to as optical cavity) is the external condition for laser generation and is an important part of laser. The simplest optical resonator consists of two mirrors coated with a highly reflective material appropriately placed at both ends of the active medium. The characteristics of high directivity, high monochromaticity, high coherence and high brightness of lasers are inseparable from optical resonators.

Optical resonators have dual functions of positive feedback and mode selection. The so-called positive feedback, that is, the initial light intensity is called round-trip propagation in the mirror, which is equivalent to increasing the length of the active medium, and finally a certain light intensity can be guaranteed. The so-called mode selection is to control the characteristics of the oscillating beam in the cavity, so that the oscillation established in the cavity is confined to a few eigenmodes determined by the cavity, thereby increasing the number of photons in a single mode, and obtaining good monochromaticity and directivity. Good strong coherent light.

Components of a Laser Cutter

3.1 Laser Source

The laser source is the core component that generates the laser beam. Depending on the type of laser cutter, the source could be a CO2 tube, a fiber laser module, an Nd:YAG crystal, or a diode array.

3.2 Optical Components

3.2.1 Mirrors

Mirrors are used to direct the laser beam from the source to the cutting head. They are usually made from highly reflective materials to minimize energy loss.

3.2.2 Lenses

Lenses focus the laser beam onto the material to be cut. The focal length and quality of the lens are crucial for achieving precise cuts.

3.3 Motion System

The motion system controls the movement of the laser cutting head. It typically includes motors, belts, and guides that ensure the cutting head moves accurately according to the design specifications.

3.4 Control System

The control system is the brain of the laser cutter. It interprets the design files and controls the laser power, cutting speed, and motion system to execute the cutting process.

3.5 Cooling System

Lasers generate a significant amount of heat, requiring an efficient cooling system to maintain optimal operating temperatures. Cooling systems can be air-based or liquid-based, depending on the laser power and application.

3.6 Exhaust System

An exhaust system removes fumes and particles generated during the cutting process, ensuring a clean working environment and preventing damage to the laser optics.

Laser-Material Interaction

The basic composition of lasers in laser cutters is a blend of advanced science and precise engineering, enabling these powerful tools to perform a wide range of tasks with unmatched accuracy and efficiency. As technology continues to advance, the capabilities of laser cutters will only expand, opening new possibilities in various industries and applications.

4.1 Absorption

The effectiveness of a laser in cutting a material depends on the material’s ability to absorb the laser energy. Different materials have different absorption characteristics based on the laser wavelength.

4.2 Heat Affected Zone

The heat affected zone (HAZ) is the area of the material that is affected by the heat of the laser. Minimizing the HAZ is crucial for maintaining the integrity and quality of the cut.

4.3 Reflectivity

Materials with high reflectivity, such as aluminum and copper, can pose challenges for laser cutting. Specialized lasers or techniques are required to cut these materials effectively.