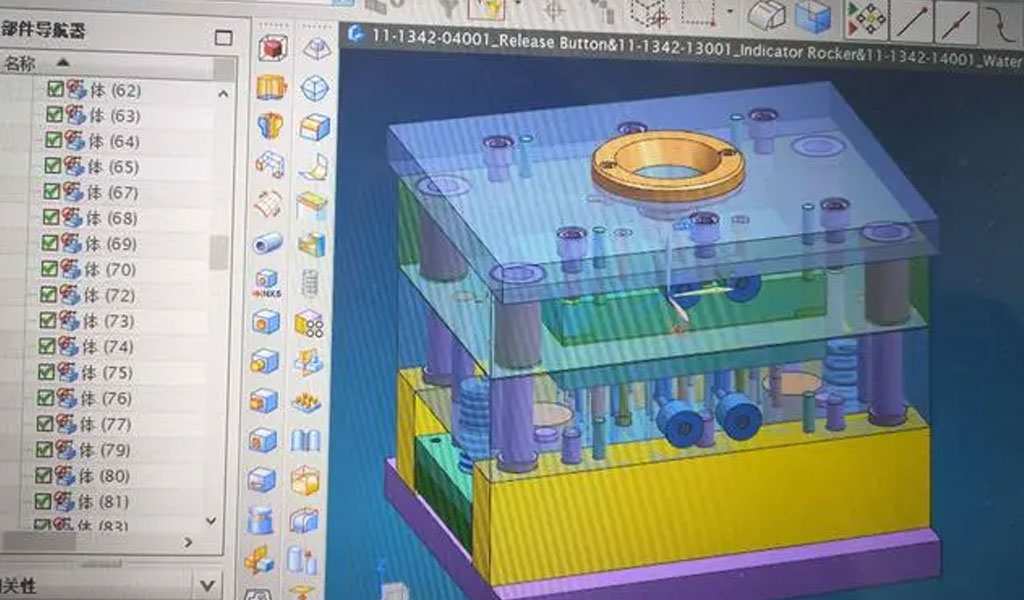

Mastercam, Creo and SolidWorks® are considered powerful CAD packages that can generate 3D models, shop drawings, and G-code for CNC machining. Mastercam, CREO (formerly Pro/ENGINEER), and SolidWorks are three popular computer-aided design (CAD) and computer-aided manufacturing (CAM) software packages used in various industries. Three programs can simulate designs to ensure they can handle the applied loads. While they share some similarities, each software has its own unique features and strengths. Each is available in various tiers of functionality and price with different features. SolidWorks® has more flexible licensing options when compared to Creo, but the baseline Creo package is more powerful than the baseline SolidWorks package. This article explores the differences between these three software products, what features they offer, their useability, system requirements, and applications.

What Is Mastercam?

Mastercam is a leading computer-aided manufacturing (CAM) software developed by CNC Software, Inc. It is primarily used in the manufacturing industry for creating toolpaths and generating instructions for computer numerical control (CNC) machines.

The Features Of Mastercam

Mastercam is a comprehensive computer-aided manufacturing (CAM) software that offers a wide range of features and tools to facilitate efficient and precise machining operations. Here are some key features of Mastercam:

- 2D Machining: Mastercam provides a variety of toolpaths and strategies for 2D machining operations. Users can perform tasks such as contouring, pocketing, drilling, engraving, and thread milling.

- 3D Machining: Mastercam offers advanced capabilities for 3D machining, including surface-based toolpaths, roughing, finishing, and rest machining. It supports complex geometries, multi spindle machining, and high-speed machining.

- Multi-Axis Machining: Mastercam supports multi-axis machining, allowing users to generate toolpaths for machines with multiple axes of movement. It includes features for indexing, simultaneous 4-axis and 5-axis machining, and tool axis control.

- Mill-Turn Machining: Mastercam provides tools for programming mill-turn machines, which combine milling and turning operations. Users can define toolpaths for both milling and turning processes, including C-axis and Y-axis milling.

- Lathe Programming: Mastercam includes features specifically designed for lathe programming. Users can create toolpaths for turning, grooving, threading, and other lathe operations. It supports live tooling and sub-spindle operations.

- Solid Modeling and CAD Integration: Mastercam allows users to import 3D models from various CAD software formats or create their own solid models. It provides tools for model preparation, feature recognition, and geometry editing.

- Toolpath Verification: Mastercam offers simulation and verification capabilities to visualize and verify toolpaths before actual machining. Users can detect potential collisions, check for toolpath errors, and analyze material removal.

- Customization and Automation: Mastercam provides customization options, allowing users to create their own tool libraries, machining templates, and macros. It also supports automation through APIs (Application Programming Interfaces) for custom programming and integration with other software.

- Post-Processing: Mastercam generates machine-specific code (G-code) to control CNC machines. It includes post-processors for a wide range of machine controllers and offers customization options for generating optimized toolpath output.

- Add-On Modules: Mastercam offers additional modules and add-ons to enhance functionality in specific areas, such as for advanced milling strategies, specialized machining operations, toolpath optimization, and robotics integration.

These features make Mastercam a powerful and versatile CAM software, suitable for various industries and machining applications. It enables efficient programming of CNC machines, optimization of toolpaths, and precise control over the manufacturing process.

The Sample Of The Mastercam

As of my last knowledge update in September 2021, here are some sample products that are part of the Mastercam software suite, as described on their website:

- Mastercam Mill: Mastercam Mill is a product within the Mastercam suite that focuses on 2D and 3D milling operations. It offers a range of toolpaths and strategies for efficient machining, including contouring, pocketing, drilling, and high-speed machining.

- Mastercam Lathe: Mastercam Lathe is specifically designed for programming CNC lathes and turning machines. It provides tools for turning operations, grooving, threading, and multi-axis milling on the lathe.

- Mastercam Router: Mastercam Router is tailored for programming CNC routers and similar woodworking machines. It offers specialized features for routing operations, such as cutting out parts, creating profiles, and carving.

- Mastercam Wire: Mastercam Wire focuses on programming CNC wire EDM (Electrical Discharge Machining) machines. It enables users to create toolpaths for cutting intricate shapes and contours using wire EDM technology.

- Mastercam Swiss: Mastercam Swiss is designed for programming Swiss-type CNC machines, which are commonly used in the watchmaking and medical industries. It supports the complex machining requirements of Swiss-type turning and milling operations.

- Mastercam Art: Mastercam Art is a module that allows users to create intricate 3D relief models and sculptural designs. It offers tools for surface modeling, texture creation, and artistic effects, suitable for applications such as jewelry design and ornamental work.

- Mastercam for SOLIDWORKS: Mastercam for SOLIDWORKS is an integration that combines the capabilities of Mastercam with the 3D CAD tools of SOLIDWORKS. It allows users to directly transfer models from SOLIDWORKS to Mastercam for CAM programming.

For the most up-to-date and comprehensive information regarding the Mastercam software suite and its product lineup, it is advisable to refer to the official Mastercam website or contact the Mastercam sales team.

What Is Creo?

CREO, now officially known as PTC CREO, is a suite of computer-aided design (CAD) software developed by PTC (Parametric Technology Corporation). It is a powerful and comprehensive 3D CAD software that enables engineers and designers to create, analyze, and visualize product designs in a digital environment.

The Features Of CREO

CREO offers a wide range of tools and capabilities for various aspects of product design and development. Some key features of CREO include:

- Parametric Modeling: CREO uses parametric modeling, which allows designers to create 3D models using parameters and constraints. This enables easy modification and updating of designs by changing the parameters.

- Assembly Design: With CREO, users can create complex assemblies by adding individual components and defining their relationships, such as constraints and connections. It provides tools for managing and visualizing assembly structures.

- Surface Modeling: CREO includes robust tools for creating complex surface geometries and freeform shapes. This is particularly useful for designing aesthetic and ergonomic products.

- Sheet Metal Design: The software offers specialized features for creating sheet metal components and designing folded and unfolded sheet metal parts.

- Simulation and Analysis: CREO includes simulation capabilities that enable engineers to perform structural, thermal, and motion analyses on their designs. This helps validate and optimize the product performance before physical prototyping.

- Manufacturing and CAM: CREO integrates computer-aided manufacturing (CAM) capabilities, allowing users to generate toolpaths for machining operations. It enables the creation of NC (Numerical Control) programs for CNC machines.

- Collaboration and PLM: CREO supports collaboration and data management through integration with Product Lifecycle Management (PLM) systems. It allows teams to work collaboratively, manage design iterations, and track changes.

CREO is widely used in industries such as automotive, aerospace, consumer products, industrial machinery, and more. Its versatility, extensive toolset, and integration capabilities make it a popular choice for product design and development.

It’s worth noting that while the software was previously known as Pro/ENGINEER or Pro-E, it was rebranded as CREO by PTC to encompass a broader set of product development tools and capabilities beyond traditional engineering.

The Sample Of The PTC CREO

As of my last knowledge update in September 2021, here are some sample products that are part of the PTC Creo suite, as described on their website:

- Creo Parametric: Creo Parametric is the flagship product of the Creo suite and offers powerful 3D CAD capabilities for product design and development. It includes features such as parametric modeling, assembly design, surface modeling, sheet metal design, and simulation.

- Creo Simulate: Creo Simulate is a simulation and analysis tool that integrates directly into Creo Parametric. It enables engineers to perform structural, thermal, and modal analyses to validate and optimize designs for performance and reliability.

- Creo Direct: Creo Direct provides a flexible and intuitive approach to 3D CAD modeling. It allows users to quickly create and modify designs using direct modeling techniques, which are particularly useful for concept design and design changes.

- Creo Illustrate: Creo Illustrate enables the creation of technical illustrations, 2D and 3D animations, and interactive service instructions directly from the 3D CAD data. It helps communicate complex product information and procedures effectively.

- Creo Schematics: Creo Schematics is a comprehensive 2D diagramming solution for creating electrical, hydraulic, and process control schematics. It provides a library of symbols, automatic report generation, and integration with other Creo products.

- Creo Additive Manufacturing: Creo Additive Manufacturing provides tools for designing and optimizing parts for additive manufacturing processes such as 3D printing. It offers features for lattice structures, build orientation optimization, and support generation.

- Creo View: Creo View allows users to visualize and collaborate on 3D CAD models, assemblies, and drawings without requiring a full CAD license. It supports markups, measurements, and multi-CAD data viewing, facilitating cross-functional collaboration.

For the most up-to-date and comprehensive information regarding the PTC Creo suite and its product lineup, it is advisable to refer to the official PTC Creo website or contact the PTC sales team.

What Is SolidWorks?

SolidWorks is a popular computer-aided design (CAD) software developed by Dassault Systèmes. It is widely used in various industries for 3D modeling, product design, simulation, and documentation. SolidWorks offers a comprehensive set of tools and features that aid in the entire product development process.

The Features Of SolidWorks

SolidWorks is a feature-rich computer-aided design (CAD) software that provides a wide range of tools and capabilities for 3D modeling, design validation, documentation, and collaboration. Here are some key features of SolidWorks:

- 3D Modeling: SolidWorks offers powerful tools for creating and editing 3D models. It supports parametric modeling, allowing users to define relationships and constraints between different parts of the design. This facilitates easy modification and updating of the model.

- Assembly Design: SolidWorks enables the creation and management of complex assemblies. Users can define relationships between components, such as mates and constraints, and visualize the assembly structure. It includes features for collision detection, interference checking, and motion simulation of assemblies.

- Sheet Metal Design: SolidWorks provides specialized tools for designing sheet metal components. Users can create and unfold sheet metal parts, define bends, flanges, and tabs, and generate flat patterns for manufacturing.

- Simulation and Analysis: SolidWorks offers integrated simulation capabilities for validating and optimizing designs. Users can perform structural analysis, thermal analysis, motion analysis, and fluid flow simulation to evaluate product performance and behavior under real-world conditions.

- Drawing and Documentation: SolidWorks allows the creation of detailed engineering drawings and documentation. Users can generate 2D drawings with annotations, dimensions, and bill of materials (BOM) directly from the 3D model. It supports automatic updates of drawings when the 3D model changes.

- Rendering and Visualization: SolidWorks provides visualization tools to create realistic renderings and presentations of designs. Users can apply materials, textures, lighting, and camera views to enhance the visual representation of their products.

- Electrical and PCB Design: SolidWorks offers solutions for electrical and printed circuit board (PCB) design. It includes tools for schematic design, wiring diagram creation, and PCB layout, enabling seamless integration between mechanical and electrical design.

- Data Management and Collaboration: SolidWorks supports data management and collaboration through its Product Data Management (PDM) solutions. It allows users to manage and control design files, track revisions, and facilitate collaboration among team members.

- Integration with Other Systems: SolidWorks integrates with other engineering software and systems, such as finite element analysis (FEA) tools, manufacturing systems, and product lifecycle management (PLM) solutions. This facilitates a streamlined workflow and data exchange between different stages of product development.

It enables efficient product design, analysis, and documentation, fostering innovation and collaboration among design teams.

The Sample Of The SolidWorks

Based on the information available up until my knowledge cutoff in September 2021, here are some sample products that are part of the SOLIDWORKS ecosystem, as described on their website:

- SOLIDWORKS 3D CAD: This is the flagship product of the SOLIDWORKS suite, offering powerful 3D modeling and design capabilities for creating complex parts, assemblies, and drawings. It includes features like parametric modeling, assembly design, sheet metal design, and simulation.

- SOLIDWORKS Simulation: This product provides integrated simulation tools for performing structural, thermal, and motion analysis on SOLIDWORKS models. It helps engineers validate and optimize their designs before prototyping, reducing costs and time to market.

- SOLIDWORKS Electrical: SOLIDWORKS Electrical enables the creation of electrical schematics, wiring diagrams, and documentation for electrical systems. It offers a library of electrical symbols, automated reports, and real-time collaboration between electrical and mechanical design teams.

- SOLIDWORKS CAM: SOLIDWORKS CAM integrates computer-aided manufacturing (CAM) capabilities directly into SOLIDWORKS, allowing users to generate toolpaths for CNC machining. It offers features for automatic feature recognition, toolpath generation, and post-processing.

- SOLIDWORKS Visualize: This product provides tools for creating high-quality visual renderings, animations, and virtual reality experiences of SOLIDWORKS models. It helps users present and communicate their designs effectively to stakeholders and customers.

- SOLIDWORKS PDM (Product Data Management): SOLIDWORKS PDM is a data management solution that helps manage and control design files, documents, and product information. It facilitates collaboration, revision control, and version management within engineering teams.

- SOLIDWORKS MBD (Model-Based Definition): SOLIDWORKS MBD enables the creation of product manufacturing information (PMI) directly in 3D models. It eliminates the need for traditional 2D drawings by including annotations, dimensions, and tolerances within the 3D CAD model.

It is advisable to refer to the official SOLIDWORKS website or contact the SOLIDWORKS sales team for the most up-to-date and comprehensive information regarding their product lineup.

Creo vs Mastercam vs. SolidWorks: Pricing Plans

The pricing plans for Creo, Mastercam, and SolidWorks can vary based on factors such as the specific edition or version, licensing options, additional modules or features, and any applicable maintenance or support contracts. It’s important to note that the pricing information provided here is a general overview, and actual pricing may vary depending on your location and specific requirements. It is recommended to contact the respective vendors or authorized resellers for accurate and up-to-date pricing details.

- Creo Pricing: Creo offers different pricing tiers or editions to cater to various needs and budgets. The pricing for Creo typically involves an upfront software license fee, with options for perpetual licenses or subscription-based licensing models. The cost can vary based on the specific modules and capabilities required, such as Creo Parametric, Creo Simulate, or Creo Additive Manufacturing. Additionally, maintenance and support fees may apply for ongoing software updates and technical assistance.

- Mastercam Pricing: Mastercam follows a modular pricing structure, allowing users to choose the specific modules and functionality they need. The cost of Mastercam depends on factors like the edition (Mill, Lathe, Router, etc.), the level of functionality required (2D, 3D, multi-axis, etc.), and the number of seats or users. Mastercam offers both perpetual licenses and subscription-based models. Additional costs may include maintenance and support fees for software updates and technical support.

- SolidWorks Pricing: SolidWorks offers different editions, each with its own set of features and pricing options. The pricing for SolidWorks typically involves an upfront license fee, which can vary based on factors such as the edition (Standard, Professional, Premium) and the desired duration of the license (perpetual or annual subscription). SolidWorks also offers additional modules and add-ons for specialized functionality, which may involve extra costs. Maintenance and support fees may apply for ongoing software updates and technical assistance.

The pricing of these software packages can be influenced by various factors such as region, market competition, customer requirements, and any promotional offers or discounts available at the time of purchase. Therefore, it’s advisable to directly contact the vendors or authorized resellers for accurate pricing information and to discuss your specific needs to get a customized quote.

Creo vs Mastercam vs. SolidWorks: Support

When it comes to support services, there are differences in the way Creo, Mastercam, and SolidWorks handle customer assistance. Here’s an overview of the support offered by each software:

1.Creo Support

- PTC Technical Support: Creo users have access to PTC Technical Support, which provides assistance through phone, email, and online support portals. PTC offers different support levels, including standard support, enhanced support, and premium support, with varying response times and service levels.

- Knowledge Base and Online Resources: PTC provides an extensive knowledge base, documentation, forums, and user communities where users can find answers to common questions, access tutorials, and participate in discussions.

- Software Updates: PTC regularly releases software updates, service packs, and new versions of Creo to address issues, introduce new features, and enhance functionality. These updates are typically available to users with active maintenance and support contracts.

2.Mastercam Support

- Mastercam Resellers: Mastercam is primarily supported through a network of authorized resellers who provide technical assistance, training, and support services. Users can reach out to their local Mastercam reseller for support, whether it’s through phone, email, or in-person interactions.

- Online Resources: Mastercam offers an online knowledge base, tutorials, documentation, and user forums to help users find answers to their questions, learn new techniques, and connect with the Mastercam community.

3.SolidWorks Support

- SolidWorks Subscription Service: SolidWorks users with an active subscription service have access to technical support provided by Dassault Systèmes, the company behind SolidWorks. Support is available through phone, email, and an online customer portal.

- SolidWorks Knowledge Base: Dassault Systèmes offers an extensive knowledge base with online help resources, tutorials, videos, and forums, allowing users to find answers to common issues, access learning materials, and participate in discussions.

- Software Updates and Service Packs: SolidWorks releases regular updates, service packs, and major versions to address software bugs, introduce new features, and improve performance. These updates are typically available to users with an active subscription service.

It’s important to note that the quality and responsiveness of support can vary based on factors such as the specific support plan, the expertise of the support team, and the availability of community resources. It’s advisable to review the support offerings, including the scope of technical assistance, response times, and the availability of resources, provided by the respective vendors or authorized resellers.

Mastercam vs Creo vs. SolidWorks: File Formats

Mastercam, Creo, and SolidWorks are all widely used in the field of computer-aided design and manufacturing (CAD/CAM), and they support various 3D file formats for compatibility with other software and data exchange. Here’s an overview of the file formats commonly associated with each software:

Mastercam File Formats:

Mastercam File Format (MCX): Mastercam has its own proprietary file format, MCX, which is used for saving Mastercam-specific data, including part files, toolpaths, and configurations.

Common CAD File Formats: Mastercam can import and work with a range of commonly used CAD file formats, including:

- IGES (.igs, .iges): Initial Graphics Exchange Specification

- STEP (.stp, .step): Standard for the Exchange of Product model data

- Parasolid (.x_t, .x_b): Native file format used by Parasolid-based CAD systems

- SAT (.sat): ACIS solid modeling file format

- SolidWorks (.sldprt, .sldasm): Native file format of SolidWorks

Creo File Formats:

Creo File Format (PRT): Creo uses its own proprietary file format, PRT, for saving Creo part files. PRT files store both the geometry and feature history of the model.

Common CAD File Formats: Creo supports several standard CAD file formats for import and export, including:

- IGES (.igs, .iges)

- STEP (.stp, .step)

- Parasolid (.x_t, .x_b)

- ACIS (.sat)

- SolidWorks (.sldprt, .sldasm)

- CATIA V4/V5 (.CATPart, .CATProduct)

- Siemens NX (.prt)

- AutoCAD (.dwg, .dxf)

- Inventor (.ipt, .iam)

SolidWorks File Formats:

SolidWorks File Format (SLDPRT, SLDASM): SolidWorks uses its proprietary file format, SLDPRT (part) and SLDASM (assembly), to save SolidWorks models. These files store both the geometry and the feature history of the model.

Common CAD File Formats: SolidWorks supports various standard CAD file formats for import and export, including:

- IGES (.igs, .iges)

- STEP (.stp, .step)

- Parasolid (.x_t, .x_b)

- ACIS (.sat)

- Creo (.prt)

- CATIA V5 (.CATPart, .CATProduct)

- Siemens NX (.prt)

- AutoCAD (.dwg, .dxf)

Additionally, all three software packages provide options to export files to neutral file formats like STL (for 3D printing) and PDF (for documentation and collaboration).

It’s important to note that the compatibility and functionality may vary between different versions and configurations of each software package. It’s always recommended to check the specific capabilities and version compatibility of the software in use when working with different file formats.

Mastercam vs Creo vs. SolidWorks: Learning Curve & Usability

Mastercam, Creo, and SolidWorks are powerful software packages used in the field of computer-aided design and manufacturing (CAD/CAM). Each software has its own learning curve and usability characteristics. Here’s an overview:

Learning Curve:

- Mastercam: Mastercam has a moderate to steep learning curve, particularly for users who are new to CAD/CAM software. Proficiency in machining concepts and a solid understanding of machining operations are beneficial. Training resources, including tutorials and classes, are available to help users learn and master the software.

- Creo: Creo has a moderate learning curve. It offers a wide range of powerful features, which can take time to fully explore and understand. The parametric modeling approach may require users to become familiar with defining relationships and constraints. PTC provides learning resources, training courses, and documentation to support users in their learning journey.

- SolidWorks: SolidWorks has a relatively gentle learning curve compared to some other CAD software. It is known for its user-friendly interface and intuitive design tools. SolidWorks employs a parametric modeling approach and offers various resources, including tutorials, forums, and training courses, to help users get up to speed quickly.

Usability

- Mastercam: Mastercam is designed specifically for manufacturing and machining processes. It offers a focused and streamlined workflow for generating toolpaths and CNC programs. Once users become familiar with the software, it is known for its efficiency and usability in the machining domain.

- Creo: Creo provides a comprehensive set of tools for product design and development. It offers a wide range of functionalities, making it suitable for complex designs. However, some users may find the interface and feature organization slightly more complex compared to other CAD software.

- SolidWorks: SolidWorks is highly regarded for its user-friendly interface and ease of use. It emphasizes ease of navigation, intuitive modeling tools, and a logical workflow. SolidWorks aims to provide a smooth and efficient design experience for users, regardless of their skill level.

That the learning curve and usability can also be influenced by factors such as prior experience with CAD software, familiarity with similar tools, and the specific requirements of the user’s industry or application.

Ultimately, the choice of software often depends on individual preferences, specific project requirements, industry standards, and the available support and training resources. Evaluating trial versions, attending training courses, and seeking user reviews can provide valuable insights when considering the learning curve and usability of these software packages.

Mastercam vs Creo vs. SolidWorks: Applications

Mastercam, Creo, and SolidWorks are all widely used in the field of computer-aided design and manufacturing (CAD/CAM) but are often preferred in different applications due to their specific strengths and capabilities. Here’s an overview of the typical applications for each software:

1.Mastercam Applications

Mastercam is primarily known for its robust capabilities in the field of machining and manufacturing. It excels in applications related to CNC (Computer Numerical Control) programming and toolpath generation. Mastercam is commonly used in industries such as:

- Moldmaking: Creating toolpaths for molds used in plastic injection molding.

- Aerospace: Programming CNC machines for aircraft components and tooling.

- Automotive: Generating toolpaths for machining automotive parts and components.

- General Manufacturing: Creating toolpaths for a wide range of manufacturing processes, including milling, turning, and wire EDM (Electrical Discharge Machining).

- Woodworking: Programming CNC routers and mills for woodworking applications.

2.Creo Applications

Creo is a comprehensive software suite that covers various aspects of product design and development. It is widely used in industries such as:

- Product Design: Creating 3D models and assemblies for a wide range of consumer products, industrial equipment, and machinery.

- Automotive and Transportation: Designing automotive components, vehicles, and transportation systems.

- Aerospace and Defense: Developing complex aerospace and defense systems, including aircraft and military equipment.

- Manufacturing and Engineering Services: Assisting in the design and engineering of custom products and providing services to other industries.

- Consumer Products: Designing consumer electronics, appliances, and other consumer goods.

3.SolidWorks Applications

SolidWorks is known for its user-friendly interface and versatility in product design and development. It is widely used in industries such as:

- Mechanical Engineering: Designing and modeling mechanical components, machinery, and industrial equipment.

- Consumer Products: Creating 3D models and assemblies for various consumer goods, including appliances, furniture, and electronics.

- Aerospace and Defense: Developing aerospace components, aircraft structures, and defense systems.

- Automotive: Designing automotive parts, vehicles, and assemblies.

- Medical Devices: Designing medical equipment, devices, and implants.

While these software packages can be used in overlapping applications, each has its own strengths and may be more preferred or commonly used in specific industries or sectors. It’s important to consider the specific needs and requirements of your industry or application when selecting the appropriate software.

The Comparison Chart Of Mastercam, CREO and SolidWorks®

Here’s a comparison table chart of Mastercam, Creo, and SolidWorks, highlighting some key aspects of each software:

| Aspect | Mastercam | Creo | SolidWorks |

|---|---|---|---|

| Primary Use | CNC programming and machining | Product design and development | Product design and development |

| Industry Focus | Manufacturing, Moldmaking, Aerospace, Automotive | Various industries including Automotive, Aerospace, Consumer Products | Various industries including Mechanical Engineering, Consumer Products, Aerospace |

| CAD Capabilities | Limited compared to Creo and SolidWorks | Extensive, robust 3D modeling tools | Extensive, robust 3D modeling tools |

| CAM Capabilities | Extensive, specialized for machining operations | Limited compared to Mastercam and SolidWorks | Limited compared to Mastercam and Creo |

| Simulation and Analysis | Basic simulation capabilities | Robust simulation and analysis features | Robust simulation and analysis features |

| File Formats | Supports various CAD file formats | Supports various CAD file formats | Supports various CAD file formats |

| Learning Curve | Moderate to steep | Moderate | Relatively gentle |

| Usability | Focused on machining operations, efficient | Comprehensive with wide range of functionalities | User-friendly and intuitive |

| Support and Resources | Technical support, training, online resources | Technical support, training, online resources | Technical support, training, online resources |

Be-Cu — Your Custom Manufacturing Partner

Be-Cu is your operating system for custom manufacturing, whether you’re injection molding, CNC machining, 3D printing, or urethane casting — our in-house of manufacturing partners has some of the most skilled operators in the world.

Plus, our design for manufacturing (DFM) feedback will help refine your CAD models to ensure success — no matter how complex your designs are, and whether you made them using Creo, Mastercam,Solidworks or another program altogether!