What Is Multi Spindle Machining

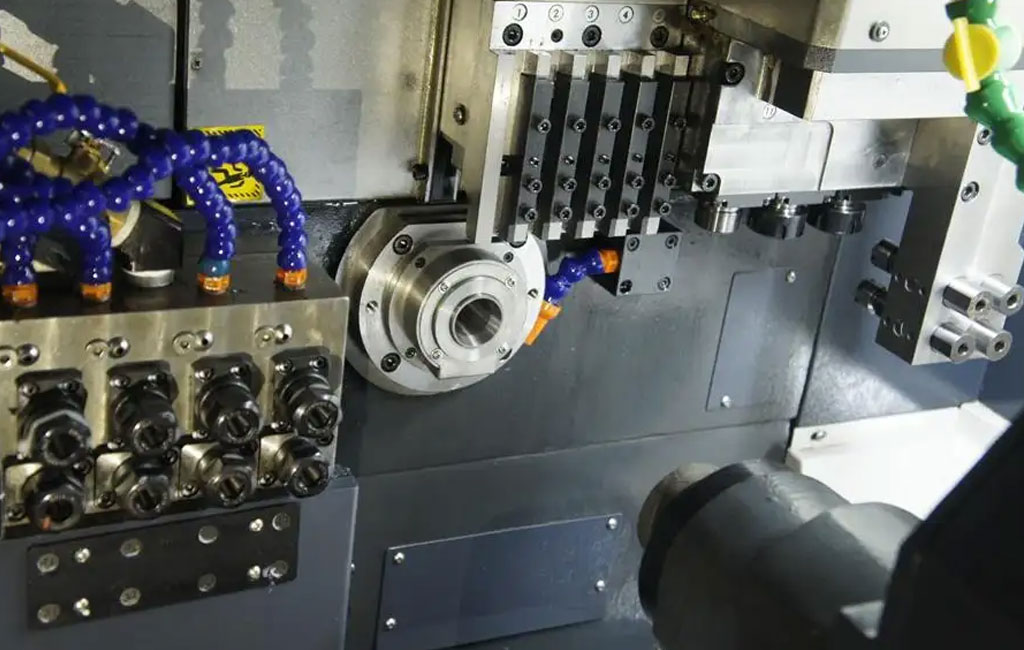

The Multi Spindle CNC Screw Machine can be used to complete all or most of the machining processes in a single setup, thus greatly reducing the manufacturing process chain. The shortened manufacturing process chain and the reduction of equipment required for the product, as well as the reduction in the number of fixtures, shop floor space and equipment maintenance costs, can effectively reduce the overall investment in fixed assets, production operations and management costs. The reduction in the number of cycles avoids the accumulation of errors due to the transformation of the positioning reference.

At the same time, Multi Spindle CNC Screw Machine is mostly equipped with in-line inspection function, which can realize in-situ inspection and precision control of key data in the manufacturing process, thus improving the machining accuracy of products. Compared with previous models, the new product adopts centralized heat source oil cooling module. After years of experience, we have analyzed the causes that affect the thermal deformation of the machine tool and cause the change of the cold and hot accuracy of the machine tool, and adopted the centralized oil cooling control heat source solution with better cooling effect in the new product for the thermal deformation problem. Effectively, the heat source points of the multi Spindle CNC screw machine and the key points that affect the stability of the machine accuracy are cooled by the oil circulation.

The Advantage Of Multi Spindle Machining

The overall structure is designed with the Multi Spindle CNC Screw Machining tool arrangement, which is particularly simple, fast in changing tools during the machining process, fast and safe in operation, and reliable and stable in the machining process. In the process of machining, any different machining tasks can be done with high precision, and the overall construction efficiency can be improved while reducing the number of feeds, and the machining tasks can be completed in a short period of time.

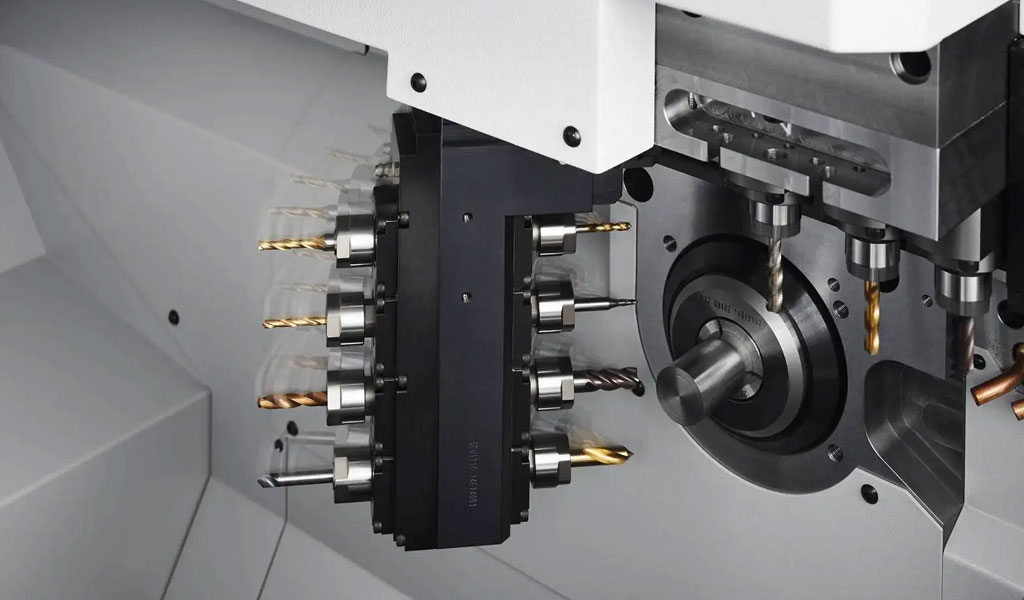

Secondly, the Multi Spindle CNC Screw Machining can reduce the waste of labor cost to a large extent, allowing the staff to complete the machining of precision parts more easily, for a variety of different high-precision parts, can easily be processed in large quantities, with high-speed synchronous guide bush, can complete the experience of machining parts in large quantities, so that high-quality parts can be High-speed cutting can naturally meet the precision requirements of various industries for parts, and can naturally complete machining with high quality.

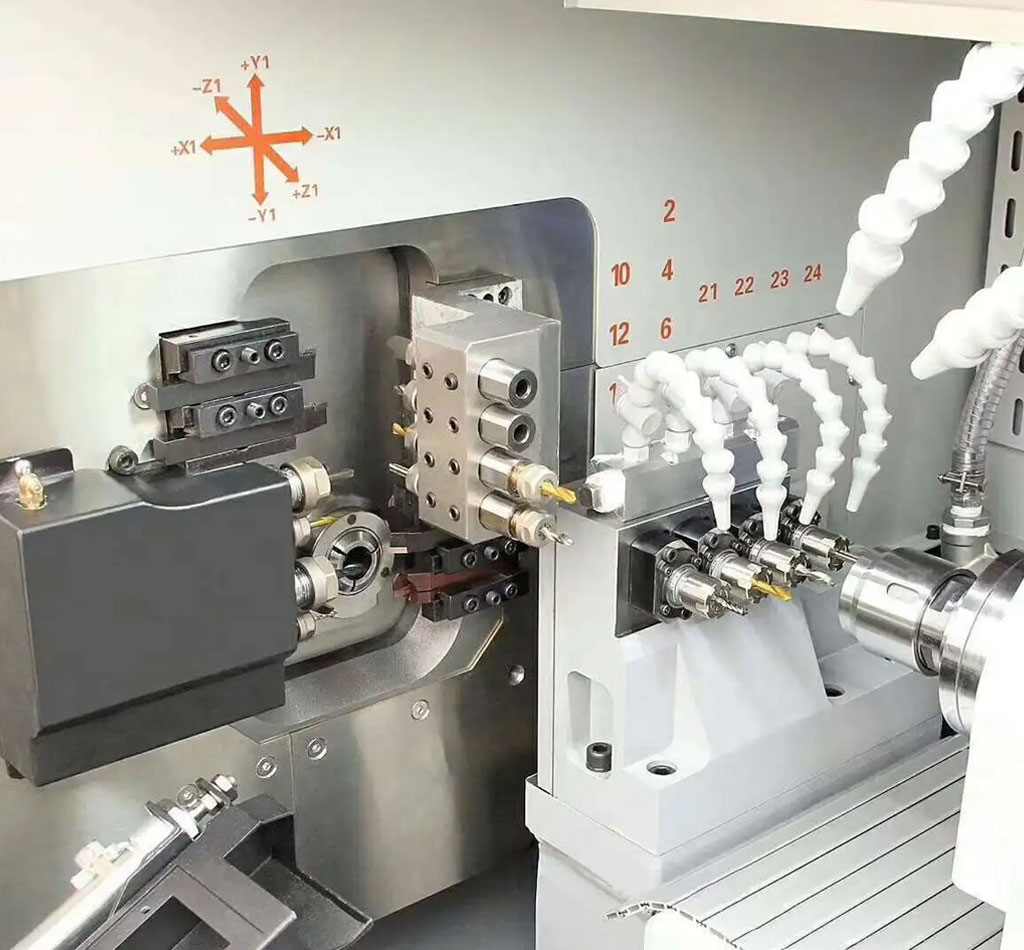

Moreover, the overall technical input level of Multi Spindle CNC Screw Machining is very high, and the design of the opposed dual spindle structure can complete all the machining sequences at once, which means that the time wastage caused by the second clamping of a part can be reduced, and on the basis of improving the rate, the machining performance and actual quality of the parts can be avoided, and the cost wastage can be controlled to a greater extent. The key is to improve machining efficiency at the same time and to complete machining tasks quickly and in a short time.

Multi Spindle CNC Screw Machining is applicable to the machining of many high-precision small parts, from iron to aluminum components to meet the requirements of the household appliance industry, optical communication industry, automatic office equipment industry and IT-related industry equipment, the main application areas are: automation components, medical equipment, digital cameras, optical communication and automotive parts, etc.

- Multi Spindle Machining without guide bush, fixed guide bush free choice, save material and high yield.

- Sub-axis optional boring tool shank, interchangeable power head all-in-one machine easily realized.

- After the parts are formed, the sub-axis out of the material, the conveyor belt automatically passed out.

- Multi Spindle Machining adopts linear rolling guide, driven by value servo motor, linear tool row structure has the characteristics of fast tool change, CNC system is well-functioning and easy to control.

- According to the parts machining needs, the side power head can be optional to realize the compound machining of drilling and milling. Equipped with automatic feeder, it can realize automatic production.

- Multi Spindle Machining integrates the functions of turning, milling, drilling, boring, tapping and so on with one equipment, can carry out end and side milling, drilling, tapping and other composite machining, especially suitable for some complex shape, high precision requirements of the machining of the rotary parts, can be completed in one clamping all or most of the processes, that is, to ensure accuracy, but also to improve the rate, reduce costs.

- The Multi Spindle Machining is designed with flexible spindle clamping auxiliary mechanism, which improves the rigidity of parts machining. The direct tool change system saves the complicated steps of tool change procedure and shortens the tool change idle time, which saves the cost of machining for users.

Multi Spindle Machining Services – Multi-Spindle CNC Screw Machining

Product Accuracy Is Our Attitude,We offer Multi-Spindle CNC Screw Machining services and multi axis cnc machining services for precision parts. Meet your requirement on price and quality.Where We Build Your precision visions

Those in the medical manufacturing industry and innovators alike choose Be-cu.com(Pintejin Group) when they need to source CNC Swiss services, create prototypes, or simply cut costs while improving product quality.

Multi Spindle Machining requirements involves precision and meticulous care throughout the entire process. Whether it’s shaft,sleeve, or complex internal components for medical equipment, Be-cu.com focuses on delivering the best precision machining available.

Be-cu.com’s ultra-precise (under .003”) Multi Spindle Machining for many industry ensures we can meet those extreme tolerances required. When it comes to machining for special applications there can be no room for inaccuracies or error.

Stainless steel, Aluminum, brass, bronze, ceramic, copper, Inconel, and many types of plastic are commonly found in Multi Spindle Machining. Other specialized materials not found in many other industries such as Kovar, gold and titanium are also regularly used.

Our Case Studies Gallery Of Multi Spindle Machining Services Parts

We are in the business of creating products that save you time and money. In addition to our Multi Spindle Machining services, we provide laser cutting, sheet metal manufacturing, die casting, and 3d printing. All customers’ orders are inspected by our team to ensure they ship complete with hardware, finish, silk-screening, electronic component assembly, and testing.

Don’t see what you are looking for? Reach out to us and learn how we can work together to create what you need.

-

Swiss Machining And Bending 304 Hand Sewing Needle For Textile Machinery

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

CNC Turning-Milling Machining Copper Facial Massage Roller

-

Swiss Turning Stainless Steel 17-4 PH Positioning Bushing

-

Precision Swiss Turning Titanium Alloy Medical Shaft

-

Swiss Turning 304 Stainless Steel Medical Threaded Rod

-

Screw CNC Machining Non-Standard Mandrel Tube Shaft

-

Swiss CNC Machining And Turning Brass 360 Shaft

-

Deep Hole CNC Turning Titanium Alloy Dispensing Needle

-

Precision Turning TC4 Alloy Medical Ultrasound Bead Needle

-

Swiss Machining Stainless Steel Alloy Medical Disposable Trocar

-

Swiss Turning Gold-Plated T2 Copper Parts

-

Swiss Machining Stainless Steel Pin Cylindrical Discharge Needle

-

Precision Swiss Machining Tooth Drive Screw Rod

-

Cnc Swiss Machining Stainless Steel 304 Taper Needle

-

Precision Swiss Machining Aluminum 3D Printer Motor Shaft