Magnetic field heat treatment has attracted much attention in the field of materials research because it can effectively improve the structure, mechanics and magnetic properties of metal materials.Chinese et al. found that suitable magnetic field heat treatment can greatly improve the coercivity and remanence ratio of Nd2Fe14B/Fe3B nano-exchange coupling magnets.

The study by S.Y.Li et al. showed that the magnetostriction of Terfenol-D2-2 composite material was increased from 860×10-6 before treatment to 1530×10-6 by magnetic field heat treatment. However, there is currently no finished magnetic heat treatment equipment in the domestic market, so there are complicated processes and unsatisfactory magnetic fields or temperature when performing magnetic heat treatment on experimental samples.

The high-vacuum magnetic field heat treatment device in this article can easily vacuum the furnace cavity. During the design process, it not only ensures the magnetic field and temperature requirements in the furnace cavity, but also controls the overall size of the magnetic field heat treatment device as much as possible. In order to more accurately reflect the temperature in the furnace cavity, this device uses two independent temperature measurement and control instruments.

Equipment composition and main technical performance parameters

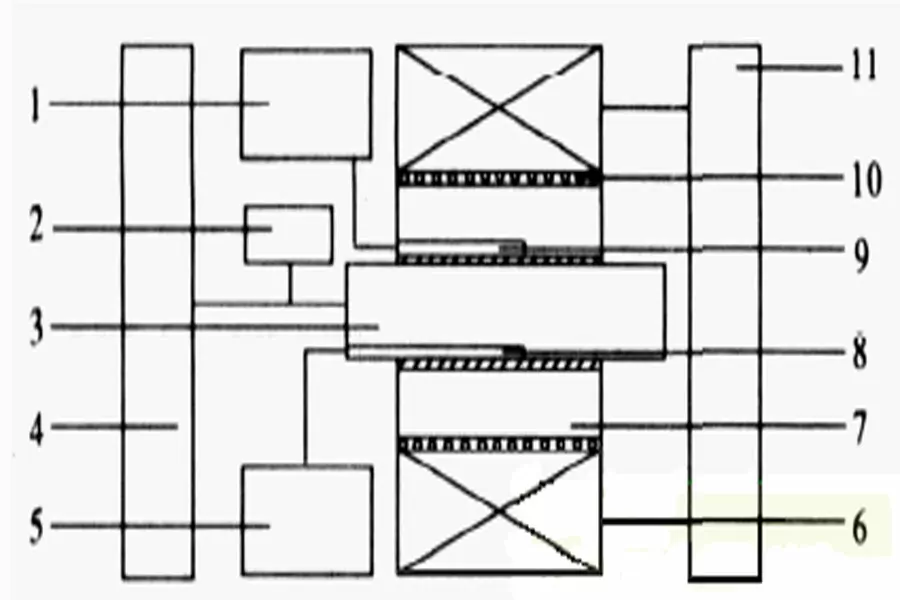

Figure 1 shows the schematic diagram of the magnetic field heat treatment device. The device is mainly composed of a DC magnetic field generator, a vacuum system and a heat treatment furnace. The related technical performance parameters are listed in Table 1.

- Tubular furnace thermostat

- Vacuum instrument

- Vacuum furnace chamber

- Diffusion pump

- Vacuum furnace chamber thermostat

- DC magnetic field generator

- Heat treatment furnace

- Thermocouple Ⅰ

- Thermocouple Ⅱ

- Water cooling pipe

- DC magnetic field power supply

If you are looking for dependable volume manufacturing metal parts supplier with High pressure die casting service who offers you competitive price, good service and quality for aluminium die casting, zinc, or magnesium die casting, then BE-CU Prototype are surely a partner you are looking for to fulfill all your die casting needs. With quality service and state of art technology, BE-CU indeed claim in providing quality pressure die casting including aluminum/zamak/magnesium alloy castings to our customers all over the world. To work with us,be-cu don’t just stop at taking your order and delivering your die casting products. be-cu are there for you at every step right from your preferred selection of aluminum die casting, Zamak die casting (Zamak 2, Zamak 3, Zamak 5, Zamak 8) or magnesium die casting products and services to post-order phase. In brief, once you become our customer, be-cu are with you every step on the way. The Detail Of BE-CU Die Casting Company

CNC Machining Gas Stove Bottom Joint

Gravity Die Casting Custom Street Light Heat Sink

Die Casting LED Canopy Lights Heatsink For Gas Station

Zinc Die Casting PA10 Transformer Connector Terminal

Die Casting Aluminium Cookware Chassis

Die Casting Wheels With Aluminum Alloy 5 Axis CNC Machining

Precision Machined Copper Die Casting Parts

Professional Small Baler Aluminum Alloy Die-casting Mold Production

China Die Casting Factory Manufactures Surface Sprayed Aluminum Valve Body

Extrusion Die-casting Polyurethane-Coated Aluminum Alloy Profiles

Custom Precision Aluminum Die Cast Brackets and Finishes

Extrusion Die-casting Magnesium Alloy Heat Sink Shell