When performing a supplier evaluation, there are several key factors to consider to ensure that you choose the right supplier for your business.For example, the percentage of on-time deliveries is quantitative, but testimonials about a supplier’s ability to fill orders with short lead times is qualitative — make sense? Here are five important factors to take into account:

Quality and Reliability

Quality and reliability are crucial factors to consider when performing a supplier evaluation. Here are some key aspects to assess:

1.Product or Service Quality

Evaluate the quality of the supplier’s products or services. Consider factors such as performance, durability, functionality, and adherence to specifications. Look for any certifications, industry standards, or quality management systems the supplier has in place. Assess their ability to consistently meet the required quality levels.

2.Quality Control Processes

Examine the supplier’s quality control processes and procedures. Investigate how they ensure the quality of their products or services throughout the manufacturing or delivery process. Consider their testing methods, inspection procedures, and any quality assurance measures they employ. A supplier with robust quality control processes is more likely to deliver consistent and reliable products.

3.Track Record and References

Research the supplier’s track record and reputation in the industry. Look for customer testimonials, reviews, or case studies that highlight their performance and reliability. Seek references from current or previous customers to gather insights into their experience with the supplier’s quality and reliability.

4.Supply Chain Management

Assess the supplier’s supply chain management practices. Evaluate their ability to source raw materials or components from reliable and reputable sources. Consider their inventory management systems, lead times, and their ability to handle unforeseen disruptions. A well-managed supply chain contributes to consistent product quality and on-time delivery.

5.Warranty and After-Sales Support

Review the supplier’s warranty policies and after-sales support. Evaluate the extent of their commitment to resolving any quality issues that may arise after the purchase. Consider their responsiveness, willingness to provide replacements or repairs, and the availability of technical support. A supplier that stands behind their products and offers comprehensive after-sales support can provide peace of mind.

By thoroughly evaluating these aspects of quality and reliability, you can choose a supplier that consistently delivers high-quality products or services, ensuring the satisfaction of your customers and the success of your business.

Cost and Pricing

Cost and pricing are critical factors to consider when performing a supplier evaluation. Here are key aspects to assess:

1.Competitive Pricing

Compare the supplier’s pricing with other competitors in the market. Request detailed pricing information, including unit costs, bulk discounts, and any additional fees or charges. Ensure that the supplier offers a competitive price for the quality and value they provide.

2.Total Cost of Ownership

Look beyond the initial purchase price and consider the total cost of ownership. Evaluate factors such as shipping costs, taxes, import duties, storage expenses, and any ongoing maintenance or support fees. Calculating the total cost over the entire product lifecycle helps you make a more accurate cost comparison.

3.Volume Discounts and Pricing Flexibility

Inquire about volume discounts or pricing flexibility based on order quantities. Assess the supplier’s willingness to negotiate and offer favorable pricing terms for larger or long-term contracts. This can help optimize costs and increase your purchasing power.

4.Payment Terms and Conditions

Review the supplier’s payment terms and conditions. Evaluate factors such as payment methods, credit terms, and any penalties or discounts associated with early or late payments. Consider the impact these terms may have on your cash flow and financial management.

5.Value for Money

Assess the supplier’s overall value proposition. Consider the balance between price and the quality of products or services provided. Evaluate any added value, such as additional features, warranty terms, customization options, or exceptional customer service. Choosing a supplier that offers the best value for your investment is crucial.

6.Cost Stability and Price Escalation

Evaluate the supplier’s historical pricing stability and their approach to price escalation. Inquire about their ability to maintain consistent pricing over time and any factors that could lead to price increases, such as inflation or raw material costs. Understanding potential cost fluctuations helps you plan and budget effectively.

By carefully evaluating cost and pricing factors, you can ensure that you choose a supplier that offers competitive prices, favorable payment terms, and a solid value proposition, enabling you to optimize your costs while maintaining the desired level of quality and service.

Track Record and References

When performing a supplier evaluation, assessing the track record and references of potential contract cnc machining suppliers is crucial. Here are key aspects to consider:

1.Supplier Experience

Evaluate the supplier’s industry experience and track record. Consider how long they have been in business and their level of expertise in supplying products or services similar to what you require. A supplier with a solid track record is more likely to have a deep understanding of your industry’s needs and be better equipped to meet them.

2.Customer References

Request references from the supplier and reach out to their current or past customers. Inquire about their experience working with the supplier, including aspects like product quality, reliability, on-time delivery, and customer service. Feedback from references provides valuable insights into the supplier’s performance and can help you gauge their suitability for your business.

3.Case Studies and Success Stories

Look for case studies or success stories related to the supplier’s past projects or collaborations. These can provide real-world examples of their capabilities and achievements. Assess how well their previous work aligns with your requirements and evaluate their ability to deliver results.

4.Reputation and Industry Recognition

Research the supplier’s reputation in the industry. Look for industry awards, certifications, or other forms of recognition they have received. A supplier with a positive reputation and industry recognition is more likely to have a proven track record of delivering quality products or services.

5.Supplier Stability

Evaluate the stability of the supplier’s operations. Assess factors such as their financial stability, organizational structure, and capacity to handle your business needs. A stable supplier is more likely to provide consistent service and have the resources to support your requirements over the long term.

6.Online Reviews and Ratings

Check online platforms and business directories for reviews and ratings of the supplier. This can provide additional perspectives from other customers or industry professionals. While online reviews should be considered with some caution, they can offer insights into the supplier’s reputation and customer satisfaction levels.

By considering the supplier’s track record and seeking references, you can gain valuable information about their performance, reliability, and reputation. This helps you make an informed decision and select a supplier that has a proven track record of meeting customer expectations and delivering satisfactory results.

Payment Terms and Conditions

When performing a supplier evaluation, it is important to carefully review and assess the payment terms and conditions offered by potential suppliers. Here are key aspects to consider:

1.Payment Methods

Evaluate the payment methods accepted by the supplier. Assess whether they align with your organization’s preferred payment methods, such as credit cards, bank transfers, or electronic payment systems. Ensure that the supplier offers convenient and secure payment options that suit your financial processes.

2.Credit Terms

Review the credit terms provided by the supplier, especially if you plan to establish a credit relationship. Consider factors such as payment due dates, credit limits, and any associated penalties or discounts. Assess whether the supplier’s credit terms align with your cash flow and financial capabilities.

3.Early Payment Discounts

Inquire about any early payment discounts offered by the supplier. Some suppliers may provide incentives, such as a percentage discount or reduced fees, for early settlement of invoices. Evaluate the potential cost savings associated with early payments and consider whether they are financially beneficial for your organization.

4.Late Payment Penalties

Understand the penalties or fees imposed by the supplier for late payments. Review their policies regarding late payment charges, interest rates, or any other consequences of delayed payments. Ensure that these penalties are reasonable and aligned with industry standards.

5.Payment Frequency and Terms

Assess the frequency and terms of payments expected by the supplier. Some suppliers may require upfront payments, while others may offer installment options or longer payment cycles. Evaluate whether the supplier’s payment frequency and terms are feasible and manageable for your organization’s financial operations.

6.Currency and Exchange Rate Considerations

If you are dealing with international suppliers, consider the currency in which payments will be made. Assess any potential risks or fluctuations in exchange rates that could impact your costs. Evaluate whether the supplier offers flexibility or hedging options to mitigate exchange rate risks.

7.Payment Dispute Resolution

Review the supplier’s policies and procedures for resolving payment disputes. Understand how they handle disagreements or discrepancies related to invoicing, pricing, or other financial matters. Ensure that the supplier has a transparent and efficient process in place to address any payment disputes that may arise.

By carefully evaluating the payment terms and conditions offered by suppliers, you can select a partner that aligns with your organization’s financial capabilities and processes. Clear and mutually beneficial payment terms contribute to a healthy business relationship and facilitate smooth financial transactions.

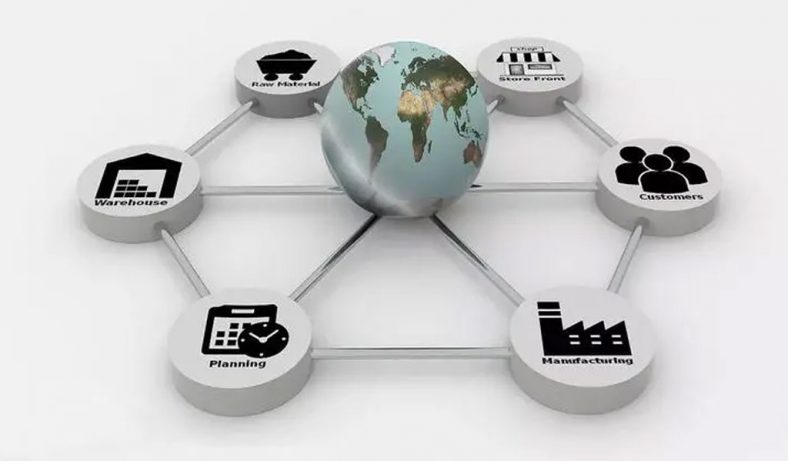

Supply Chain Management

Supply chain management plays a crucial role in supplier evaluation as it directly impacts your business operations and overall efficiency. When assessing potential suppliers, consider the following aspects related to supply chain management:

1.Supplier’s Network and Capabilities

Evaluate the supplier’s network and capabilities within their supply chain. Assess their ability to source raw materials, components, or finished goods efficiently and reliably. Consider their relationships with subcontractors, logistics providers, and other key stakeholders. A well-established and robust supply chain network indicates their capacity to meet your requirements effectively.

2.Inventory Management

Assess the supplier’s inventory management practices. Evaluate their ability to maintain optimal inventory levels, minimize stockouts, and manage demand fluctuations. An efficient inventory management system ensures timely availability of products or materials, reducing disruptions in your own operations.

3.Lead Times and On-Time Delivery

Evaluate the supplier’s lead times and track record of on-time delivery. Consider their historical performance in meeting delivery deadlines and fulfilling orders promptly. Reliable and consistent on-time delivery is critical to maintaining a smooth production or service schedule and meeting customer demands.

4.Risk Management

Assess the supplier’s approach to risk management within their supply chain. Inquire about their strategies for mitigating potential risks such as disruptions, delays, or quality issues. Evaluate their contingency plans, backup suppliers, and disaster recovery procedures. A supplier with robust risk management practices demonstrates their commitment to minimizing potential disruptions to your business.

5.Transparency and Communication

Evaluate the supplier’s transparency and communication practices within their supply chain. Assess their ability to provide timely updates on order status, potential delays, or any other relevant information. Open and transparent communication fosters collaboration and enables you to make informed decisions based on real-time information.

6.Sustainability and Ethical Practices

Consider the supplier’s commitment to sustainability and ethical practices within their supply chain. Assess their compliance with environmental regulations, labor standards, and social responsibilities. Evaluate their policies regarding ethical sourcing, fair trade, responsible manufacturing, and corporate social responsibility initiatives. Choosing a supplier with strong sustainability practices aligns with your values and reduces reputational risks.

7.Continuous Improvement Initiatives

Inquire about the supplier’s efforts for continuous improvement within their supply chain. Assess whether they invest in technology, process optimization, or innovation to enhance their supply chain efficiency and responsiveness. A supplier committed to ongoing improvement can bring added value to your business through increased efficiency and better service.

By evaluating these supply chain management aspects, you can choose a supplier that demonstrates strong capabilities, reliable delivery, effective risk management, and a commitment to sustainability. This ensures a well-functioning supply chain and supports the overall success of your business.

Responsiveness and Communication

Consider the supplier’s responsiveness and communication skills. Assess their ability to address inquiries promptly, provide accurate information, and maintain effective lines of communication. A supplier who is proactive, transparent, and readily available can help avoid potential issues and foster a smooth working relationship.

Ethical and Sustainability Considerations

Examine the supplier’s commitment to ethical practices and sustainability. Evaluate their compliance with environmental regulations, labor standards, and social responsibilities. Assess their policies regarding human rights, fair trade, diversity, and inclusion. Choosing a supplier that aligns with your values and meets your sustainability objectives can enhance your reputation and mitigate any potential risks.

Simplify Supplier Evaluation and Get the Parts You Need

Supplier evaluations are complicated, and there’s more to consider than whether you receive good parts at the lowest price. For example, if you need design for manufacturing (DFM) assistance, will you be able to get it? Be-Cu works with a carefully vetted network of expert manufacturing partners and provides DFM assistance along with our response to your request for a quote. We can also help you go from rapid prototype to production, seamlessly.