Laser radium engraving technology has gradually entered people’s daily life, such as mobile phone back shell patterns, light switches, plastic buttons in the central control of automobiles, and the fonts (patterns) in them may be realized by laser radium engraving technology.

Why Is The Effect Of Laser Engraving Uneven?

When laser engraving patterns, processors may often encounter such a question: “Why is the effect of laser engraving uneven?”There are several reasons for the uneven effect:

- The level of the machine table is not adjusted properly, that is, the galvanometer lens or field lens lens is not parallel to the processing table;

- Since the two are not level, the distance between the laser beam and the object to be processed will be inconsistent after passing through the field lens. Finally, the energy of the laser falling on the object to be processed will have inconsistent energy density, which will show the effect on the material uneven.

- The laser output spot is blocked, that is, after the laser beam passes through the galvanometer and the field mirror, the spot is missing and not round enough;

- The laser output head, fixing fixture and galvanometer are not adjusted properly, which causes part of the light spot to be blocked when the laser passes through the galvanometer evenly.

- There is also a situation that the galvanometer deflection lens is damaged, and when the laser beam passes through the damaged area of the lens, it cannot be reflected well. Therefore, the laser energy of the laser beam passing through the damaged area of the lens is inconsistent with that of the non-damaged area of the lens, and the final laser energy acting on the material is also different, so that the marking effect is uneven.

- Use off-focus to mark a certain range of content;

- Because each focusing lens (field lens) has a corresponding focal depth range, and the defocusing method will easily lead to a large-scale marking pattern, the edge is at the focal depth critical point or beyond the focal depth range, so it is easier to causing unevenness in the effect. Therefore, the method of off-focus marking must consider the problem of laser energy.

- Thermal lens phenomenon;When the laser passes through the optical lens (refraction, reflection), it will cause the lens to heat up and cause slight deformation. This deformation will raise the focus of the laser and shorten the focal length. If the machine is fixed and the distance is adjusted to the focal point, after the laser is turned on for a period of time, the laser energy density acting on the material will change due to the thermal lens phenomenon, resulting in uneven marking effect.

- Material reasons, such as inconsistent film thickness on the material surface or changes in physical and chemical properties;

- Materials are sensitive to laser energy. Usually under the same material, the laser energy reaches a certain material damage threshold. When the thickness of the material coating is different, or some other physical and chemical treatment processes are not uniform enough, it will also cause unevenness in the effect of laser marking.

The Solution For Uneven Laser Engraving Effect

Uneven laser engraving effects can be frustrating and may lead to unsatisfactory results in your project. Fortunately, there are several solutions to address this issue and achieve a consistent and even laser engraving effect. Let’s explore some potential causes and their corresponding solutions:

Uneven Material Surface

Cause: If the material being engraved has an uneven surface or is not perfectly flat, the laser beam may not focus evenly across the entire area, resulting in inconsistent engraving depth and quality.

Solution: Ensure that the material is properly positioned and secured during the engraving process. Use fixtures or jigs to hold the material flat and steady to prevent any movement or warping.

Inconsistent Laser Power

Cause: Inconsistent laser power settings can lead to uneven engraving. Variations in power can occur due to factors like power supply fluctuations or improper calibration.

Solution: Calibrate and verify the laser power settings regularly to ensure consistent and accurate engraving results. Use a power meter or engrave a test pattern on a scrap piece of material to confirm the laser power output.

Incorrect Focal Point

Cause: An incorrect focal point can lead to uneven engraving. If the focal point is too high or too low, the laser beam may not have the desired focus, resulting in uneven engraving depth.

Solution: Adjust the focal point to the optimal distance from the material’s surface. Follow the manufacturer’s guidelines for setting the correct focal length based on the material and lens used.

Dirty or Misaligned Lens

Cause: Dust, debris, or misalignment of the laser lens can scatter the laser beam, leading to uneven engraving results.

Solution: Regularly clean the laser lens with appropriate cleaning tools to ensure it is free from any particles that may obstruct the laser beam. Check and align the lens according to the manufacturer’s recommendations.

Inconsistent Engraving Speed

Cause: Variations in the engraving speed can cause uneven results, with areas engraved too quickly or too slowly.

Solution: Maintain a consistent engraving speed throughout the entire project. Adjust the settings to achieve the desired depth and quality while ensuring even and uniform engraving.

Material Compatibility

Cause: Some materials may react differently to laser engraving due to variations in composition or surface properties, leading to uneven results.

Solution: Test the laser engraving settings on a sample piece of the material before proceeding with the actual project. This allows you to determine the optimal parameters and prevent potential issues.

Machine Maintenance:

Cause: A poorly maintained laser engraving machine can result in uneven engraving effects. Dust, debris, or worn components can affect the machine’s performance.

Solution: Regularly clean and maintain the laser engraving machine as per the manufacturer’s guidelines. Replace worn components and ensure that the machine is in good working condition.

By addressing these potential causes and implementing the suggested solutions, you can achieve consistent and even laser engraving effects, resulting in high-quality and visually appealing outcomes for your projects.

The Detail Of BE-CU Laser Cutting Company

BE-CU.COM Laser Cutting provides services to a wide network of industries and markets. BE-CU is uniquely positioned to Laser Cut, Laser Engrave, Precision CNC Machine and Precision Finish Grind parts and components.We use large format industrial laser cutting machines that are extremely precise with up to .001” tolerance. Not only we cut and engrave your project, we are ready to answer any questions you may have about the process and give you expert advice.

So, reach out even if you’re unsure of your specific need or if you think you may require a different type of manufacturing service(as laser cutting medical parts). Laser cutting service by BE-CU makes ordering your parts simple. Just upload your CAD files onto the platform for an instant price and lead time. Our mission is to save engineers’ time for value-adding activities.

-

Etching LED EMC Packaging Bracket

-

Etching Low Resistivity Copper 110 Contact Rings

-

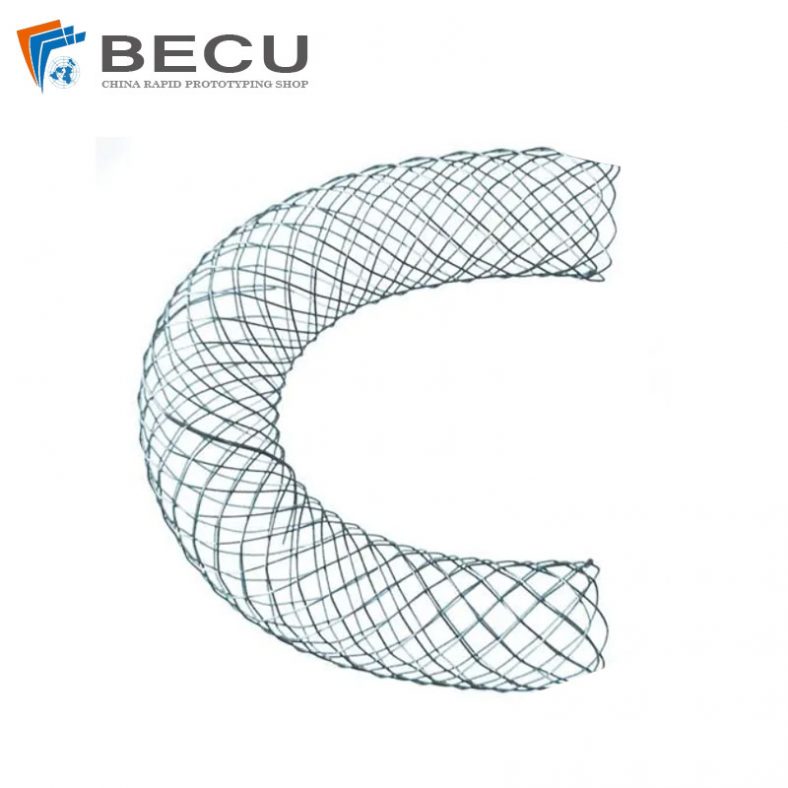

Laser Cut Nitinol Stent For Bile Duct

-

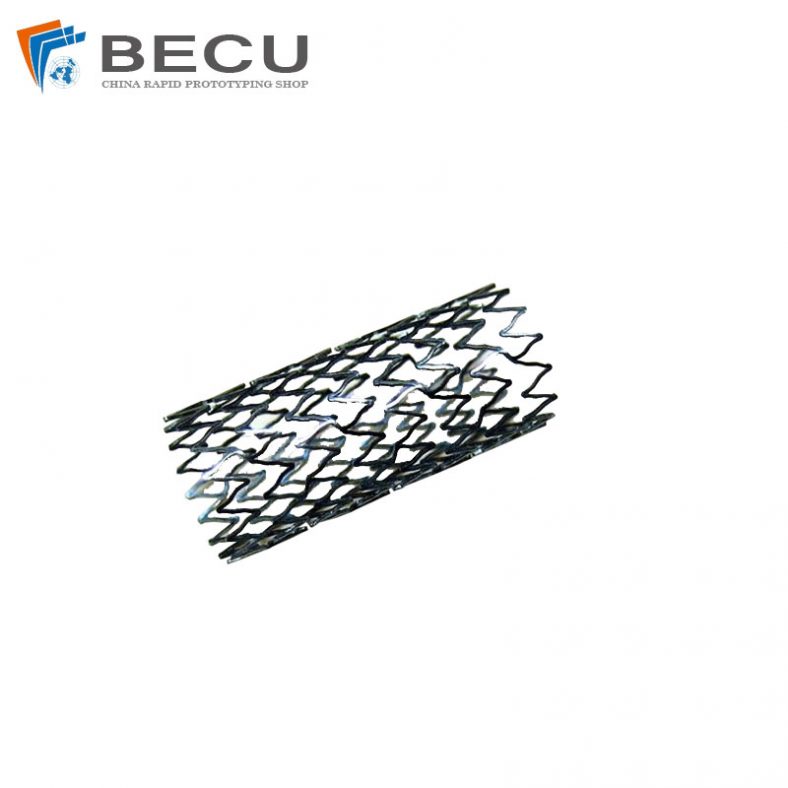

Stents For Carrying Valves And Venous Valve Replacement Devices

-

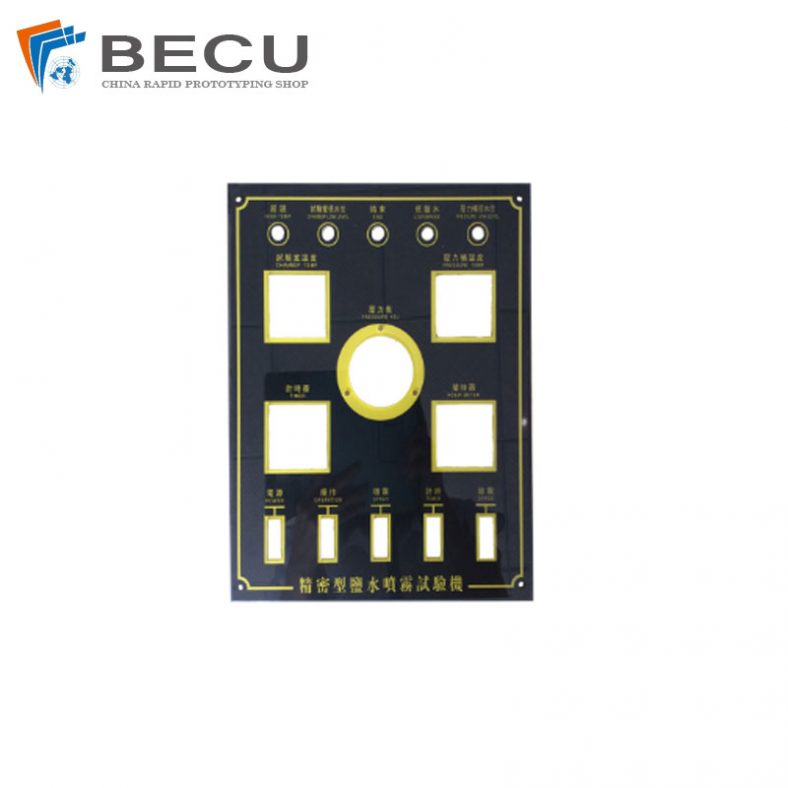

Laser Cutting PC Anti-Static Membrane Switch

-

Precision Engraving Special-Shaped Natural Color PEEK Parts

-

Acrylic Laser Cut Signs

-

Acrylic Laser Cut Earrings