For a manufacturing enterprise, improving production capacity often starts with technological transformation in terms of production management, manufacturing technology, production equipment, etc., and these parts of the content influence and restrict each other. In the process of technical transformation, when selecting the updates, maintenance, and procurement of production equipment and CNC machine tools, we must consider the environment in which they will be used, how to manage them, and how to achieve the best economic results.

The selected manufacturing equipment is to serve the manufacturing of certain products. The selected equipment may be used for part of the process processing of product parts, or it may be used for all process processing. The level of manufacturing first depends on the design of the process, which will determine the methods and means used for processing, which also determines the basic requirements for the equipment used, which is also the basis for technical organization and management of production. After the basic requirements for equipment selection are determined, the selection must be based on what technical level of equipment can be provided on the market. For most manufacturing companies with small and medium-sized batches, it is a development trend to choose CNC machine tools to replace old machine tools or enhance production capacity.

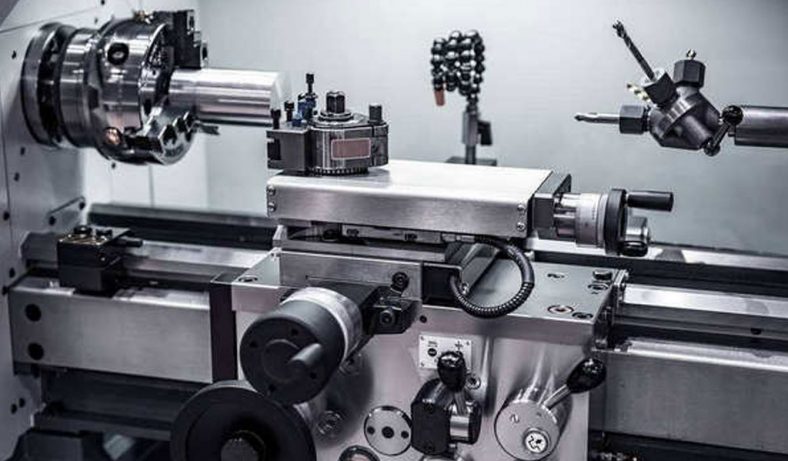

Comparing the performance of ordinary and CNC machine tools, CNC machining china tools have strong ability to process parts with complex shapes and are adaptable to a variety of processing objects (strong flexibility); high processing quality, precision and processing efficiency; adaptable to CAD/CAM networking, and suitable for manufacturing processing information Integrated management; high equipment utilization and low normal operating costs.

Choosing CNC machine tools is a comprehensive technical issue. Nowadays, a variety of equipment can be produced and provided both at home and abroad. After decades of development, CNC machine tools have evolved into a large family group that can complete a variety of processing and manufacturing requirements. How to choose suitable equipment from a wide variety of expensive equipment, how to make these equipment fully play a role in manufacturing and meet the future development of the enterprise, how to correctly and reasonably choose accessories, tools, and software that match the host machine technology, after-sales technical services, etc., so that the purchased equipment can achieve a better investment ratio… These are issues that the majority of purchasers must consider and deal with one by one.

Determine the typical machining workpiece “family”

Determining what kind of parts to process is the first step in selecting equipment. Based on the needs of technological transformation and production development, enterprises determine which parts and processes are to be completed with new processing equipment, and the long-term planning of product development must be taken into consideration. Use grouping technology to group and classify these parts to determine the typical part families that prepare the main processing objects. During classification, we often encounter problems such as part specifications and sizes that vary greatly, part shapes vary greatly, and the processing hours of various parts greatly exceed the full load hours of the equipment. Therefore, it is necessary to further select typical workpiece families that determine the production program and are closer to the requirements. . Typical workpiece families can be divided into diamond-shaped types (box types), plate types, rotary types (discs, sleeves, shafts, flanges) and special-shaped types according to their appearance; according to processing accuracy requirements, they can be divided into ordinary grade and precision grade. wait. The classification of typical parts is clear, and the basic processing equipment is relatively clear.

Process planning design of typical part families

After determining the parts to be processed, new planning and design of the process flow must be carried out from the perspective of CNC machining technology. This includes changing the original process production process, exploring the feasibility of implementing new process methods, and exploring the implementation of modern production management and logistics management. Feasibility, explore the feasibility of using advanced tooling and tooling to greatly improve production efficiency, explore the reasonable preparation process of CNC equipment and other equipment (ordinary, special machines) on the production line, etc., with the purpose of hoping to get the best results from using CNC machine tools Process manufacturing process. The following are reasonable processing techniques for several typical types of parts.

Fixed cycle function

Machining parts with CNC machine tools, some typical processing procedures, such as drilling, boring, deep hole drilling and tapping, etc., the action cycles to be completed are very typical, these typical actions are pre-programmed and stored in memory , use the code to instruct, form the fixed cycle function, the fixed cycle function can greatly simplify the programming.

Compensation function

During machining, due to tool wear or tool replacement. And the lead screw pitch error and backlash in the mechanical threading will make the size of the actually machined parts inconsistent with the size specified in the program, resulting in machining errors. The compensation function of the device is to input the compensation amount of the length or radius of the tool, the pitch error and the one-way gap error into its memory, and the memory will recalculate the path and coordinate size of the tool according to the compensation amount, and process the parts that meet the requirements.

Communication function

The device usually has an interface, and some also have an interface, which can be connected to a variety of input and output devices to realize the input and output storage of programs and parameters. adapt to the requirements.

Man-machine dialogue programming function

Some devices can be programmed directly according to the blueprint. The programmer only needs to input a few simple commands on the drawing, and then all the intersection points, tangent points and center coordinates can be automatically calculated to generate the processing program. Some devices can carry out conversational programming according to the instructions and display of the guide map, and some devices are also equipped with user macro programs.

User macro programs are a set of programming language-macro programming instructions provided by the user according to the device. Some special processing programs written by oneself can be transferred from the main program of the part when used, and can be reused. Operators who have received programming training can use it to program quickly.

At Be-cu.com,we use advanced equipment to offer you Unparalleled precision for producing metal and plastic machining parts

- We combine the latest CNC milling and turning processes with proprietary technology to deliver high quality, on-demand parts.

- Our team of engineers and machinists program the equipment to optimize cutting time, surface finish, and final tolerance to meet your design specifications

- We specialize in cnc precision machining, single part prototyping, short to medium production runs, manufacture parts on time, every time, so you can stay ahead of schedule

- CNC machining can create very similar parts to series parts. It is often more efficient and faster than other rapid prototyping technologies for the manufacture of a quantity of prototypes between 1 and 10 parts . We also recommend CNC machining for parts with large sizes (greater than 600 mm).

Contact Us ([email protected]) Now for your Custom CNC Machining, We are your best online cnc machining and rapid prototyping services choice!