CNC (Computer Numerical Control) machine tools can have different types of drive devices for their vertical and horizontal movements. These drive devices are responsible for translating the programmed instructions into precise motion, enabling the CNC machine to cut, shape, and machine various materials. Let’s explore the common types of drive devices for both vertical and horizontal movements in CNC machine tools:

Vertical Drive Devices

- Ball Screw Drive: Ball screws are a widely used drive mechanism in CNC machines for vertical movement. They consist of a threaded shaft (screw) and a nut with recirculating ball bearings. As the motor rotates the ball screw, the nut moves linearly, providing precise vertical motion. Ball screws offer high efficiency, low friction, and high positioning accuracy.

- Rack and Pinion Drive: In some CNC machines, particularly in CNC routers and plasma cutters, a rack and pinion drive system is used for vertical movement. The vertical axis is moved using a rack (a flat, toothed bar) and a pinion (a small gear). When the pinion rotates, it engages with the rack, causing the vertical movement. This system is simple, cost-effective, and provides fast vertical motion.

- Linear Guideway Drive: CNC machines equipped with linear guideways may use linear motors or servo motors to drive the vertical axis. Linear guideways provide smooth and precise linear motion. Linear motors are directly coupled to the axis and eliminate the need for intermediate components like ball screws or gears, reducing mechanical backlash and improving response times.

Horizontal Drive Devices

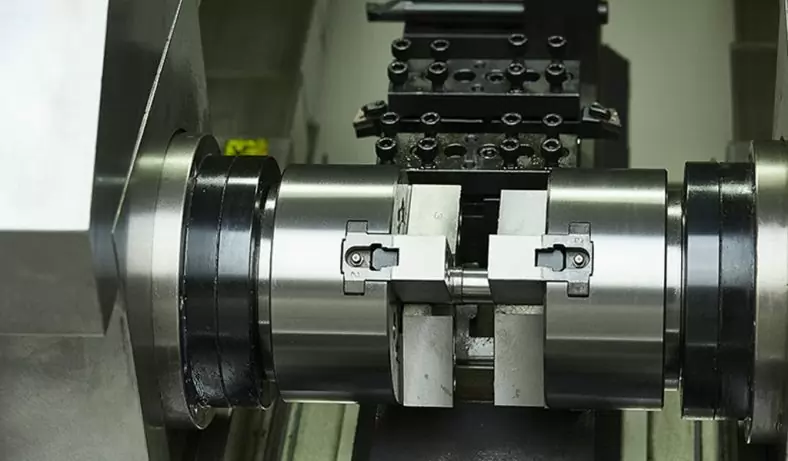

- Ball Screw Drive: Ball screws are also commonly used for the horizontal movement in CNC machines. Similar to the vertical axis, the ball screw provides precise linear motion for the horizontal axis. The horizontal table or spindle moves along the ball screw, driven by a motor, to execute the programmed toolpath.

- Rack and Pinion Drive: CNC machines with a gantry structure or large horizontal travel may employ a rack and pinion system for the horizontal movement. This system offers rapid and smooth motion for the horizontal axis.

- Linear Guideway Drive: For CNC machines with linear guideways, the horizontal axis can be driven by linear motors or servo motors, similar to the vertical axis. This configuration ensures precise and high-speed horizontal motion.

The final dimensional accuracy and contour accuracy of the workpiece are directly affected by the transmission accuracy, sensitivity and stability of the feed movement. For this reason, the feed transmission system of the CNC machine tool should have the characteristics of low friction, high transmission accuracy and cutting degree, and can eliminate the transmission gap and reduce the inertia of the moving parts.The feeding system of the CKA6150 CNC horizontal lathe is realized by the servo system through the ball screw transmission to the slide plate and the tool rest.The vertical and horizontal driving devices are all driven by the white servo system through the synchronous toothed belt to drive the ball screw and nut pair. Realize longitudinal and transverse infeed movements.

The Characteristics Of CNC machine Ball Screw Pair Transmission

- High transmission efficiency and low friction loss: The transmission efficiency of the ball screw is as high as 92%~969e, and the power consumption is equivalent to 1/4 to 1/3 of the ordinary screw transmission. At the same time, due to the low heat generation, high-speed movement can be achieved.

- The transmission is stable, and it is not easy to crawl. Due to the rolling friction of CNC machine tools, the difference between the dynamic and static friction coefficients is extremely small. Therefore, the low-speed and high-speed transmission of CNC machine tools are very stable.

- High positioning accuracy and high transmission rigidity. Numerical control machine tools can eliminate the axial clearance of the screw nut by various methods, so that there is no empty stroke in the reverse direction, and the positioning accuracy is high. After proper preloading, the axial rigidity can also be improved.

- It cannot be self-locking and is reversible. CNC machine tools can convert both rotary motion into linear motion and linear motion into rotary motion. Therefore, when the lead screw is used in a vertical state, a braking device should be added.

- The manufacturing cost is high. The machining accuracy and surface roughness of components such as ball screws and nuts of CNC machine tools are high, the manufacturing process is complex, and the cost is high.

Choose the appropriate drive device based on the specific requirements of the CNC machine, including its size, load capacity, cutting speed, and accuracy demands. Each drive device has its advantages and limitations, and the selection depends on factors like application, budget, and desired performance. Regular maintenance and calibration are crucial to ensuring the proper functioning and accuracy of the CNC machine’s drive devices.

At Be-cu.com,we use advanced equipment to offer you Unparalleled precision for producing metal and plastic machining parts

- We combine the latest CNC milling and turning processes with proprietary technology to deliver high quality, on-demand parts.

- Our team of engineers and machinists program the equipment to optimize cutting time, surface finish, and final tolerance to meet your design specifications

- We specialize in cnc precision machining, single part prototyping, short to medium production runs, manufacture parts on time, every time, so you can stay ahead of schedule

- CNC machining can create very similar parts to series parts. It is often more efficient and faster than other rapid prototyping technologies for the manufacture of a quantity of prototypes between 1 and 10 parts . We also recommend CNC machining for parts with large sizes (greater than 600 mm).

Contact Us ([email protected]) Now for your Custom CNC Machining, We are your best online cnc machining and rapid prototyping services choice!