In recent years, with the continuous development of society, it has become better and better.Whether it is in machine tool bearings or aerospace bearings, most of them now use silicon nitride ceramic materials. very good. In order to give you a better understanding of it, Be-Cu Ceramics will introduce to you in detail the excellent properties of silicon nitride ceramic bearings.

Through continuous exploration and accumulation, Be-Cu Ceramics has mastered the qualified ceramic molding process, and has cultivated a group of precision machining backbones. We have a complete production and machining industry chain, which greatly saves the production of products.

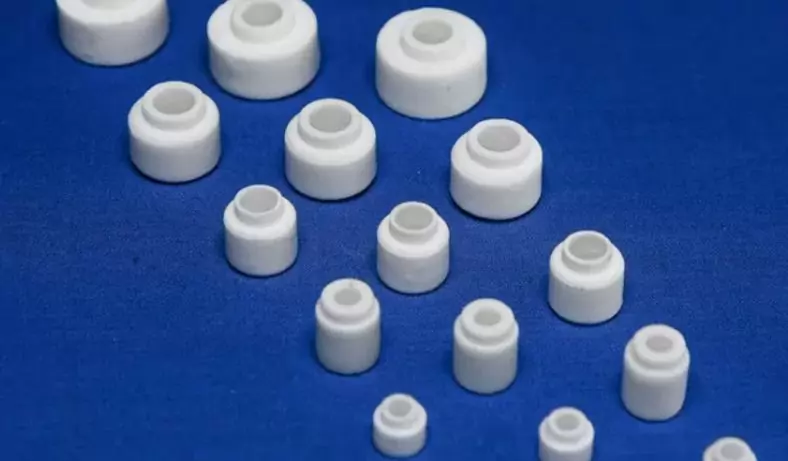

The Excellent Properties Of Silicon Nitride Ceramic Bearings

We keep our original mission in mind and provide better service for everyone. Our professional after-sales team is online 24 hours a day to serve you.

- First of all: The reason why silicon nitride ceramic bearings can work in special environments and situations is due to the characteristics and functions of silicon nitride ceramics. The editor believes that friends who have a certain understanding of silicon nitride ceramics should know that the elastic modulus of silicon nitride ceramics is much higher than that of metals, and the elastic deformation of silicon nitride ceramics after being stressed can be to a certain extent. To reduce the vibration of the machine tool, there are many ultra-fine machine tool spindles and high-precision aerospace bearings that use silicon nitride ceramic materials for machining applications.

- Secondly: the hardness of silicon nitride ceramics is very high, so the bearings made of silicon nitride ceramics have many advantages, and also have excellent wear resistance, high temperature resistance, wear resistance and other superior properties. In addition, the mechanical strength of silicon nitride ceramics is also very high, its tensile strength and flexural strength are similar to those of metal, and its compressive strength is extremely high, especially under the conditions of high temperature and high temperature environment, silicon nitride Ceramic bearings can still maintain high strength and hardness, so compared with bearings of other materials, the service life of silicon nitride ceramic bearings will be longer.

- Finally: the friction coefficient of silicon nitride ceramics is very small, so silicon nitride ceramic bearings have low heat generation performance. Compared with metal materials, silicon nitride ceramics still have poor thermal conductivity, which makes nitrogen Silicon nitride ceramic bearings generate very little heat during operation, so silicon nitride ceramic bearings are favored by many industries.

The excellent properties of silicon nitride ceramic bearings are shared here. It is precisely because the performance characteristics of silicon nitride ceramic materials are very superior, so the bearings made of it have won many industry fields. Widely used, and silicon nitride ceramic bearings and slide bearings cnc machining have become one of the indispensable products in many industries, and may be more popular in the near future.Be-Cu Ceramics insists on meeting customer needs with pragmatic work, exceeding customer expectations with innovative technology, and achieving a win-win situation for both parties with an honest attitude.

Since its establishment, Be-Cu Ceramics has vigorously introduced advanced ceramic zirconia and alumina machining equipment and sophisticated testing equipment, so that the product quality can be controlled in an all-round way, and all performance indicators are at the leading domestic level. At the same time, it has also received more attention from customers. Be-Cu Ceramics hopes to maintain a permanent partnership with you all the time.

About China Advanced Ceramic CNC Machining Company - Be-Cu

Manufacturer of precision machined components. Ceramic cnc machining components include high dielectric strength, electrical & corrosion resistance, & non-porous & non-shrinking properties.Manufacturer of high temperature fabricated and machinable ceramics including alumina, glass-ceramic, alumino-silicate, boron nitride and zirconium phosphate. Adhesives, coatings and potting compounds to 3200 degrees F,Air firing services for ceramics up to 1650 degrees C also available. Products include insulators, guides, washers, tubes, blocks, & rods for thermal, electrical, corrosion exposure, structural, wear, & semi-conductor operations. Services include machining to tolerances of +/- .0001, ultrasonic core drilling, centerless grinding, milling, & ID & OD threading.Surface grinding, dicing, OD (outer dia.) grinding, ID (inner dia.) grinding, centerless grinding, hole drilling, jig grinding, lapping, honing & polishing service are also available. Diamond grinding with dimensional tolerances of 5 microns & surface finishes of 0.2 microns (8 micro-in.) can be performed.Blanket orders and AutoCAD files & other 3d files accepted.Contact us for your machining ceramic project!

-

Metal Plating ZrO2 Zirconia Ceramic Parts

-

ZrO2 Structural Ceramic Semiconductor Parts

-

Alumina Ceramic Screw Type Parts

-

Cnc Machining Alumina Ceramic Screw Heating Pipe

-

Brushed Fishing Tackle Alumina Ceramic Accessories

-

Winding Machine Alumina Ceramic Wire Wheel

-

Insulation Device Microcrystalline Ceramic Multi-Slot Ceramic Column

-

99 Alumina Ceramic Spool Insulator Sleeve

-

The Alumina Ceramic Ring Of Textile Machine Thread Passing Wheel

-

Isostatic Pressure Insulation Alumina Ceramic Column