In the vast and diverse landscape of science, engineering, manufacturing, and everyday life, precise measurement holds the key to progress and innovation. The science that deals with the principles, methods, and applications of accurate measurement is known as metrology. Metrology is a fundamental discipline that underpins various industries, research fields, and technological advancements. In this comprehensive post, we will embark on a journey into the captivating world of metrology, exploring its historical roots, fundamental principles, methods, cutting-edge techniques, and the profound impact it has on society.

The Define Of Metrology?

Metrology is the science and art of precise measurement. It encompasses the principles, methods, and techniques used to measure various physical attributes with a high degree of accuracy and precision. The ultimate goal of metrology is to ensure that measurements are reliable, consistent, and traceable to internationally recognized standards.In everyday life, we encounter measurements in various forms, such as time, length, temperature, weight, volume, and more. These measurements are essential for a wide range of applications, from manufacturing and engineering to scientific research, healthcare, and environmental monitoring.

These measurements are essential for a wide range of applications, from cnc machining service and engineering to scientific research, healthcare, and environmental monitoring.

Key Concepts in Metrology:

- Accuracy: Accuracy refers to the closeness of a measured value to the true or accepted value. It indicates how well a measurement represents the actual quantity being measured.

- Precision: Precision relates to the consistency or repeatability of a measurement. It refers to how closely repeated measurements of the same quantity match one another.

- Measurement Units and Standards: To ensure uniformity and standardization in measurements, metrology relies on agreed-upon units and standards. The International System of Units (SI) is the globally recognized system of measurement used as a basis for most measurements.

- Traceability: Traceability is the ability to link a measurement result to a known standard through an unbroken chain of comparisons. It ensures that measurements can be trusted and verified by a higher authority.

- Calibration: Calibration is the process of comparing the measurement instrument with a known standard to determine any deviations or errors. It allows for adjustments to be made to maintain the accuracy of the instrument.

- Industrial Metrology: Industrial metrology involves applying precise measurement techniques to ensure product quality, process control, and compliance with industry standards.

- Scientific Metrology: Scientific metrology focuses on improving measurement accuracy for research and experimentation, particularly in scientific fields like physics, chemistry, and biology.

- Advanced Metrology Techniques: Over the years, metrology has evolved to include advanced techniques such as interferometry, scanning probe microscopy, and X-ray metrology, enabling nanoscale measurements and non-destructive material analysis.

Metrology is a foundational discipline that enables progress and innovation across multiple domains. Its continuous refinement and application contribute to the growth of science, industry, and technology, propelling society forward into an era of precision and accuracy.

The Historical Evolution of Metrology

Metrology, the science of measurement, has a long and fascinating historical evolution that dates back thousands of years. Throughout history, the need for accurate and standardized measurements has been essential for trade, commerce, construction, and scientific endeavors. Here is a brief overview of the historical evolution of metrology:

Ancient Times

The origins of metrology can be traced back to ancient civilizations such as the Egyptians, Mesopotamians, and the Indus Valley Civilization. These early societies developed basic measurement systems for length, weight, and volume, often based on natural reference points like body parts or locally available materials.

Egyptian Metrology

Ancient Egypt is particularly known for its advanced measurement techniques used in architecture and construction. The Egyptian cubit, a standardized length based on the forearm’s length, was used for various building projects, including the construction of the pyramids.

Mesopotamian Metrology

The ancient Mesopotamians developed the shekel, a standardized weight measurement used for trade and economic activities. They also utilized other units of measurement for length, area, and volume.

Greek Metrology

The Greeks made significant contributions to metrology, with individuals like Hipparchus and Eratosthenes measuring the Earth’s circumference and developing the first map of the world. The Greek mathematician Archimedes is also known for his work on determining the density of objects, which played a crucial role in developing measurement techniques for volume.

Roman Metrology

The Romans further refined and standardized measurements, especially for length and weight. The Roman mile, derived from the Latin “mille passus” (a thousand paces), became a common unit of length.

Medieval and Renaissance Period

During the medieval and Renaissance periods, various European regions had their local measurement systems, leading to inconsistencies in trade and commerce. Efforts were made to standardize measurements, culminating in the development of the metric system.

Development of the Metric System

The French Revolution of the late 18th century provided an opportunity for radical reforms, including the creation of a unified measurement system. In 1791, the French Academy of Sciences established the metric system based on the decimal system, with the meter as the unit of length. The system was gradually adopted worldwide, and it remains the predominant international system of measurement today.

Modern Metrology

In the 19th and 20th centuries, metrology evolved further with the development of precise instruments and standards for measuring various physical quantities. The establishment of international organizations such as the International Bureau of Weights and Measures (BIPM) in 1875 helped promote global standardization of measurements.

Contemporary Metrology

In modern times, metrology has expanded to encompass various fields, including industrial, scientific, and technological applications. With advancements in technology, metrologists now utilize highly sophisticated instruments and methodologies to ensure accurate and reliable measurements across different domains.

The historical evolution of metrology reflects the constant quest for accuracy, precision, and standardization in measurement practices, shaping the world of science, engineering, and trade as we know it today.

Fundamentals of Metrology

The fundamentals of metrology encompass the basic principles and concepts that underpin the science of measurement. These principles are crucial to ensure accuracy, consistency, and reliability in all measurement processes. Here are some key fundamentals of metrology:

Measurement Traceability:

Measurement traceability is the ability to trace the result of a measurement back to a recognized and documented reference standard. It ensures that the measurement process is reliable and that the measurement can be compared to established standards to confirm its accuracy.

Standardization:

Standardization involves the establishment of universally accepted and consistent units of measurement. Standardization ensures that measurements are understood and recognized across different regions and industries, facilitating international trade and scientific collaboration.

Units of Measurement:

Units of measurement provide a standard reference for quantifying various physical quantities. The International System of Units (SI) is the most widely used and recognized system, encompassing seven base units (e.g., meter, kilogram, second) and various derived units (e.g., Newton, Watt, Pascal).

Calibration:

Calibration is the process of comparing a measuring instrument or system to a known standard to determine its accuracy and correct any deviations. Regular calibration is essential to maintain the reliability and accuracy of measurement instruments.

Uncertainty:

Uncertainty is an inherent part of any measurement. It represents the range of possible values within which the true value of the measured quantity lies. Metrologists calculate and report uncertainty to provide a measure of the measurement’s reliability.

Measurement Error:

Measurement error refers to the difference between the measured value and the true value of the quantity being measured. Errors can be due to various factors, such as instrument inaccuracies, environmental conditions, and operator mistakes.

Metrology Infrastructure:

A well-established metrology infrastructure includes accredited laboratories, national metrology institutes, and international organizations, such as the International Bureau of Weights and Measures (BIPM). These organizations maintain and disseminate measurement standards, ensuring global consistency.

Metrology in Science and Industry:

Metrology is essential in various fields, including science, engineering, manufacturing, healthcare, and environmental monitoring. Accurate measurements are crucial for research, quality control, and regulatory compliance.

Legal Metrology:

Legal metrology involves regulations and standards governing measurements used in trade, commerce, and public safety. It ensures fair transactions and consumer protection by enforcing accuracy requirements for measuring instruments used in commercial activities.

Metrology Software and Data Analysis:

In modern metrology, sophisticated software tools are used to analyze measurement data, assess uncertainties, and optimize measurement processes. These tools help metrologists achieve higher accuracy and efficiency.

Understanding and applying these fundamentals of metrology is essential to ensure that measurements are reliable, consistent, and fit for their intended purpose, contributing to the advancement of science, technology, and society as a whole.

Metrology in Practice

Metrology in practice involves the application of measurement principles and techniques to obtain accurate and reliable measurements in various fields. It plays a crucial role in a wide range of industries and scientific disciplines. Here are some key areas where metrology is applied in practice:

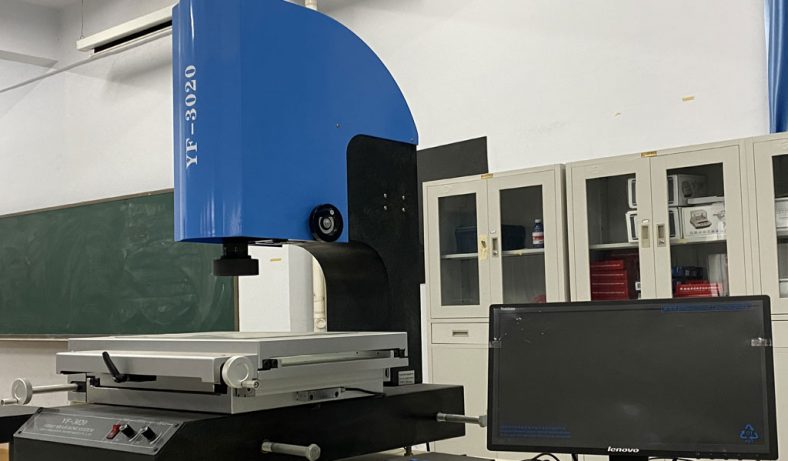

- Manufacturing and Quality Control:In manufacturing industries, metrology is essential for ensuring the quality and consistency of products. It involves measuring and inspecting various components and finished goods to verify their compliance with design specifications. Metrology tools, such as coordinate measuring machines (CMMs), optical scanners, and gauges, are used to assess dimensional accuracy and surface quality.

- Aerospace and Defense:In aerospace and defense, precision is paramount. Metrology is used in the design, production, and maintenance of aircraft and military equipment. It ensures that critical components meet strict tolerances and adhere to safety standards.

- Automotive Industry:Metrology plays a significant role in the automotive industry. It is used to assess engine components, body parts, and other vehicle elements to ensure proper fit, functionality, and safety.

- Healthcare:In the healthcare sector, metrology is vital for medical devices, diagnostics, and pharmaceuticals. Accurate measurements are essential for patient diagnosis, treatment, and safety.

- Nanotechnology and Semiconductor Manufacturing:In nanotechnology and semiconductor manufacturing, metrology is used to measure and control structures and features at the nanoscale. It ensures the precise fabrication of microchips and other nanoscale devices.

- Environmental Monitoring:Metrology is employed in environmental monitoring to measure various parameters, such as air quality, water quality, and climate data. Accurate measurements are crucial for understanding and addressing environmental issues.

- Research and Scientific Studies:Metrology is a fundamental aspect of scientific research. It is used to measure physical constants, study fundamental properties of matter, and verify the results of experiments.

- Calibration Services:Metrology laboratories provide calibration services to ensure the accuracy of measurement instruments. Calibration involves comparing a device’s measurements to traceable standards, adjusting if necessary, and issuing calibration certificates.

- Legal Metrology and Trade:Legal metrology ensures fair trade and consumer protection. It involves regulations for measuring instruments used in commercial transactions, such as weighing scales and fuel dispensers.

- Space Exploration:Metrology is essential for space missions, where precision is critical. Accurate measurements are required for navigation, space probes, and other space-related activities.

Overall, metrology is a fundamental aspect of modern society, impacting numerous industries and scientific disciplines. Accurate measurements provided by metrology are essential for product quality, safety, scientific advancement, and global trade.

Advanced Metrology Techniques

Interferometry

The interferometry of visible light is the first developed and most widely used category of interferometry. Early practical applications such as the measurement of the angular diameter of stars by the Michelson star interferometer, but how to obtain a stable coherent light source is always a limitation One of the important reasons for the development of optical measurement. Until the 1960s, optical interferometry technology developed rapidly, thanks to the invention of laser, a high-intensity coherent light source, the ability of computers and other digital integrated circuits to acquire and process the data obtained by interferometers was greatly improved, and The application of single-mode fiber increases the effective optical path in the experiment and still keeps the noise very low [25]. The development of electronic technology makes people no longer need to observe the interference fringes produced by the interferometer, but can directly measure the phase difference of coherent light.

Scanning Probe Microscopy

Scanning Probe Microscopy (SPM) is a powerful tool for examining surfaces at the nanoscale, enabling researchers to visualize and manipulate individual atoms and molecules.

Scanning probe microscopes include atomic force microscopes (AFM), magnetic force microscopes (MFM), electrostatic force microscopes (EFM), scanning near-field optical microscopes (SNOM) and a series of microscopic devices with similar working principles.

X-ray Metrology

X-ray measurement method is a kind of non-destructive testing method. Its basis is that ray testing is mainly divided into: photographic testing, real-time imaging testing and tomographic imaging.

X-ray inspection equipment can be used to detect defects in casting and welding processes, and can also be used for quality inspection in industries such as industry and electronics, or for safety inspection in the field of public safety, and research on dynamic processes such as ballistics, explosions, and casting technology.

Metrology and Society

The future of metrology is expected to be shaped by various technological advancements and evolving needs in different industries. Here are some key trends and possibilities for the future of metrology:

Advancements in Measurement Technology:

Metrology instruments and techniques will continue to evolve with the rapid progress of technology. High-precision sensors, 3D scanners, non-contact measurement methods, and portable metrology solutions will become more widespread, allowing for faster and more accurate measurements.

Industry 4.0 and Smart Manufacturing:

Metrology will play a central role in Industry 4.0, the fourth industrial revolution characterized by smart manufacturing and automation. Integrating metrology with manufacturing processes will enable real-time quality assurance and process optimization, leading to increased productivity and reduced waste.

Artificial Intelligence (AI) and Data Analytics:

AI and data analytics will be integrated into metrology systems, allowing for automated data analysis, pattern recognition, and anomaly detection. This will streamline decision-making processes and improve the efficiency of metrology operations.

Internet of Things (IoT) and Metrology:

IoT will enable the interconnectivity of metrology instruments, creating a network of sensors and devices for continuous monitoring and control. This will facilitate predictive maintenance and real-time data sharing across the supply chain.

Quantum Metrology:

Quantum metrology is a cutting-edge field that explores the use of quantum phenomena, such as entanglement and superposition, to enhance measurement precision beyond classical limits. Quantum sensors may revolutionize high-precision measurements in the future.

Metrology for Nanotechnology and Microelectronics:

As advancements in nanotechnology and microelectronics continue, metrology will be crucial for characterizing and fabricating nano-scale devices and structures with unprecedented precision.

Metrology in Space Exploration:

Metrology will remain essential for space missions and planetary exploration. Precise measurements will be crucial for navigation, landing, and conducting scientific experiments in space.

Metrology for Sustainable Development:

As the world focuses on sustainable development and environmental protection, metrology will play a vital role in monitoring and measuring environmental parameters, such as air and water quality, to support sustainable practices.

Quantum Computing and Metrology:

The emergence of quantum computing could revolutionize how metrologists analyze complex data and perform simulations, opening up new possibilities for advancing measurement science.

Global Standardization and Collaboration:

International collaboration and standardization efforts will continue to promote uniformity in measurements, ensuring global compatibility and facilitating international trade.

The future of metrology holds exciting prospects for improved accuracy, efficiency, and applicability across various industries and scientific disciplines. As technologies continue to advance, metrologists will be at the forefront of driving innovation and ensuring the reliability of measurements that underpin our modern world.

Sourcing Simplified – Start Your Next Project With Be-Cu

Metrology, as the science of precise measurement, has a profound and far-reaching impact on the way we understand the world and make progress in various fields. From its ancient origins to the forefront of quantum technologies, metrology continues to be a driving force behind innovation, quality, and safety. As we venture into a future filled with unprecedented technological advancements, metrology will remain an indispensable tool, unlocking the precision required for humanity to thrive and navigate uncharted territories.

If you’re looking for a partner to provide you with accurate measurement results and manufacture your products to your exact requirements every time — regardless of tight tolerances or part complexity — then look no further. Be-Cu has what you need.