Zirconia ceramics are actually not very new. Now they are used more in all walks of life. Zirconia ceramics mainly contain oxygen elements and zirconium elements to form oxides. Zirconia ceramics usually have a certain oxygen content.

Why Test the Oxygen Content

Many friends are asking to measure the oxygen content in zirconia ceramics, why? The amount of oxygen content will determine the use effect of zirconia ceramics, so this part of the composition must be accurately detected. Be-Cu Ceramics specializes in machining and producing various ceramic workpieces and ceramic structural parts. We will briefly introduce why we need to test the oxygen content in zirconia ceramics.

It is impossible to do such high-tech work without some professional skills. For this reason, an oxygen content analyzer has been specially launched, which can quickly and effectively detect zirconia ceramics.

Oxygen content analyzer has become an ideal analysis device for detecting the oxygen content of zirconia ceramics due to its simple structure, good quality, high sensitivity and fast corresponding speed.

It is designed according to the principle of concentration difference electricity in electrochemistry.

Oxygen molecules take electrons from the platinum electrode to become oxygen ions, making the platinum electrode the cathode of the battery. Oxygen ions pass through the zirconia ceramic dielectric to the side with low concentration and lose electrons to the platinum electrode, and become oxygen so that the platinum electrode becomes the anode of the battery, thus forming a concentration battery with zirconia as the electrolyte, and an electromotive force will be generated between the two electrode plates.

When the zirconia ceramic is heated to a certain temperature, the logarithm of the ratio of the oxygen concentration in the measuring gas to the reference gas is proportional to the electromotive force between the two polar plates, so as long as the electromotive force is measured, the oxygen in the measured gas can be known. content.

In addition to analyzing the oxygen purity in zirconia ceramics, this device can also analyze trace oxygen in high-purity hydrogen and high-purity nitrogen. It only needs to adjust the analyzer to the corresponding range according to the content of trace oxygen in the gas. .

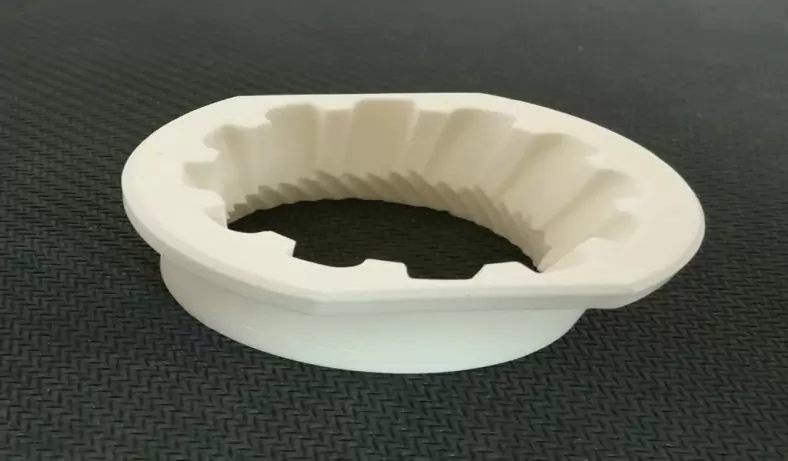

Zirconia ceramics have different properties due to their different oxygen content. It is suitable for oxygen and zirconium elements to reach a certain ratio. The machining and preparation of ceramic materials are actually relatively rare. The zirconia ceramics produced by Be-Cu Ceramics use standard ratios High-concentration zirconia ceramics are processed to obtain various ceramic parts, such as ceramic rods, ceramic plates, ceramic rings, etc.

About China Advanced Ceramic CNC Machining Company - Be-Cu

Manufacturer of precision machined components. Ceramic cnc machining components include high dielectric strength, electrical & corrosion resistance, & non-porous & non-shrinking properties.Manufacturer of high temperature fabricated and machinable ceramics including alumina, glass-ceramic, alumino-silicate, boron nitride and zirconium phosphate. Adhesives, coatings and potting compounds to 3200 degrees F,Air firing services for ceramics up to 1650 degrees C also available. Products include insulators, guides, washers, tubes, blocks, & rods for thermal, electrical, corrosion exposure, structural, wear, & semi-conductor operations. Services include machining to tolerances of +/- .0001, ultrasonic core drilling, centerless grinding, milling, & ID & OD threading.Surface grinding, dicing, OD (outer dia.) grinding, ID (inner dia.) grinding, centerless grinding, hole drilling, jig grinding, lapping, honing & polishing service are also available. Diamond grinding with dimensional tolerances of 5 microns & surface finishes of 0.2 microns (8 micro-in.) can be performed.Blanket orders and AutoCAD files & other 3d files accepted.Contact us for your machining ceramic project!

-

Metal Plating ZrO2 Zirconia Ceramic Parts

-

ZrO2 Structural Ceramic Semiconductor Parts

-

Alumina Ceramic Screw Type Parts

-

Cnc Machining Alumina Ceramic Screw Heating Pipe

-

Brushed Fishing Tackle Alumina Ceramic Accessories

-

Winding Machine Alumina Ceramic Wire Wheel

-

Insulation Device Microcrystalline Ceramic Multi-Slot Ceramic Column

-

99 Alumina Ceramic Spool Insulator Sleeve

-

The Alumina Ceramic Ring Of Textile Machine Thread Passing Wheel

-

Isostatic Pressure Insulation Alumina Ceramic Column