The ceramic dispensing valve of the dispensing machine is composed of a cylinder, a valve body and a glue outlet. The valve body and the cylinder should be separated by a diaphragm. The purpose is to prevent the glue from invading the air cavity. The valve in the glue outlet must be fixed at On the piston rod, the purpose of using the valve is to open and close the glue.

The Correct Way To Use The Graphite Engraving And Milling Machine?

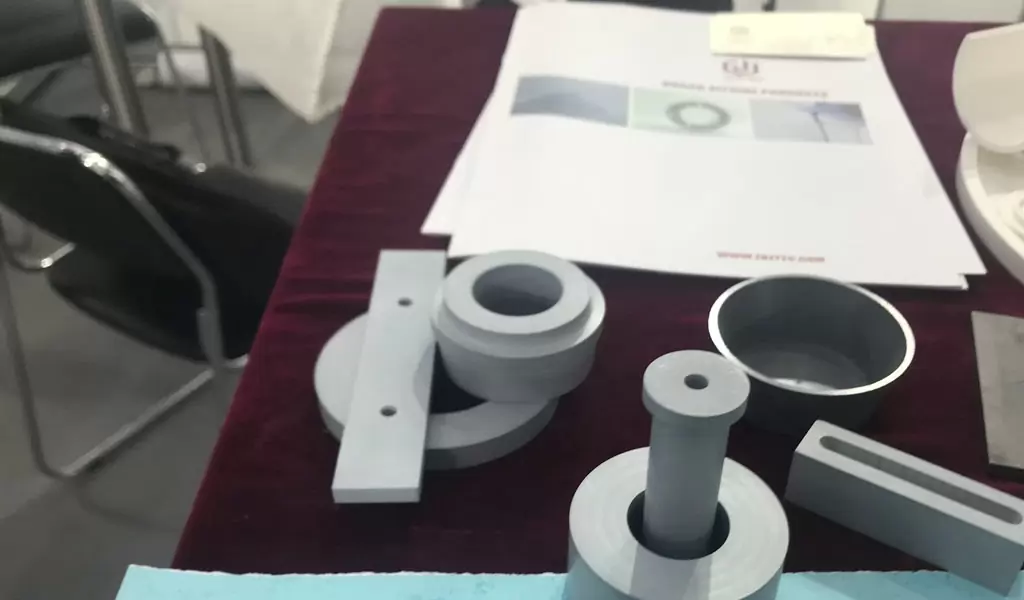

Be-Cu Ceramics has a strong development and production capacity, applies advanced production equipment and reasonable and innovative production technology, and is a professional manufacturer of ceramic machining. Our products are of good quality, and the products we provide can definitely reassure users. The professional ability of Be-Cu ceramics, the practice of abiding by contracts and keeping promises are unanimously recognized in the industry. The technicians from Be-Cu Ceramics’ rich experience share with you why the dispensing machine uses a ceramic dispensing valve.

Why Use Zirconia Ceramics

The working principle of the dispensing valve: it means that the compressed air is fed into the glue bottle, and the glue is pressed into the same feed pipe as the piston chamber. If the piston is in a stroke, the piston chamber is filled with glue. When the dispensing needle is advanced, the glue is pressed out of the needle nozzle. The amount of glue dripped is mainly determined by the distance of the plunger, which can be adjusted manually or controlled in the software.

- Leakage of the rubber valve: It is very common for the traditional dispensing valve to leak from the rubber valve. These situations are mainly caused by the small diameter of the needle used. Metal dispensing valve is not resistant to high temperature, it is extremely easy to paste colloidal liquid, and it will affect the action of air bubble removal. However, the ceramic dispensing valve can solve the leakage phenomenon of the glue valve very well, and the back pressure generated is very small, and the liquid flow is also very smooth.

- Liquid dries up in the valve: Mainly due to excess moisture or reused instant glue. The metal dispensing valve will cause the valve body temperature to become cold due to the working environment. However, the ceramic dispensing valve can ensure that it is in a constant temperature state, and the liquid will not dry up during the process of flowing through the valve body, ensuring normal circulation.

- Inconsistent glue size: This phenomenon is mainly caused by the instability of the pressure cylinder or air pressure that stores the fluid. The intake pressure regulator is set 10 to 15 psi below the lowest pressure in the job site. The pressure used by the pressure cylinder should be above the pressure in the middle of the pressure regulator, and it is necessary to prevent the pressure from being in the low pressure part of the pressure gauge. However, the minimum control pressure of the ceramic dispensing valve is more than 60psi, which can effectively ensure stable glue discharge, and has high temperature resistance and corrosion resistance, and will not cause the phenomenon of glue liquid flow blockage.

- The flow rate of the dispensing valve is too slow: it is also caused by the material of the metal dispensing valve itself. The metal temperature is too high, and the liquid will coagulate when it flows through. Size is inconsistent. The ceramic dispensing valve made of zirconia ceramics can solve this problem very well, because zirconia ceramics itself has the performance of high temperature resistance and wear resistance, even at a high temperature of 1400°C, it can ensure the normal flow of liquid.

The correct way to use the graphite engraving and milling machine is shared here by Be-Cu Ceramics. Why to use a ceramic dispensing valve It is a good solution to these problems, which is the main reason why the dispenser uses a ceramic dispensing valve. Be-Cu Ceramics has a strong development and production capacity, applies advanced production equipment and reasonable and innovative production technology, and is specialized in precision ceramics machining. Our products are of good quality, and the products we provide can definitely reassure users.

About China Advanced Ceramic CNC Machining Company - Be-Cu

Manufacturer of precision machined components. Ceramic cnc machining components include high dielectric strength, electrical & corrosion resistance, & non-porous & non-shrinking properties.Manufacturer of high temperature fabricated and machinable ceramics including alumina, glass-ceramic, alumino-silicate, boron nitride and zirconium phosphate. Adhesives, coatings and potting compounds to 3200 degrees F,Air firing services for ceramics up to 1650 degrees C also available. Products include insulators, guides, washers, tubes, blocks, & rods for thermal, electrical, corrosion exposure, structural, wear, & semi-conductor operations. Services include machining to tolerances of +/- .0001, ultrasonic core drilling, centerless grinding, milling, & ID & OD threading.Surface grinding, dicing, OD (outer dia.) grinding, ID (inner dia.) grinding, centerless grinding, hole drilling, jig grinding, lapping, honing & polishing service are also available. Diamond grinding with dimensional tolerances of 5 microns & surface finishes of 0.2 microns (8 micro-in.) can be performed.Blanket orders and AutoCAD files & other 3d files accepted.Contact us for your machining ceramic project!

-

Metal Plating ZrO2 Zirconia Ceramic Parts

-

ZrO2 Structural Ceramic Semiconductor Parts

-

Alumina Ceramic Screw Type Parts

-

Cnc Machining Alumina Ceramic Screw Heating Pipe

-

Brushed Fishing Tackle Alumina Ceramic Accessories

-

Winding Machine Alumina Ceramic Wire Wheel

-

Insulation Device Microcrystalline Ceramic Multi-Slot Ceramic Column

-

99 Alumina Ceramic Spool Insulator Sleeve

-

The Alumina Ceramic Ring Of Textile Machine Thread Passing Wheel

-

Isostatic Pressure Insulation Alumina Ceramic Column