What Is Chemical Etching

Chemical etching is the technique of removing material using chemical reaction or physical impact. This method makes full use of advanced computer-aided technology to make the graphics required by customers into film, and then re-engraves the film graphics onto the surface of the metal plate through photochemical reactions, forming protected metal parts graphics on the surface of the metal material, and then through etching. The unprotected metal material is etched away, thereby producing the metal part.Compared with the traditional stamping process, the chemical etching process is extremely cost-effective, which is entirely due to the use of film, which is different from the stamping process that requires an additional mold fee, which not only increases the manufacturing cost but also increases the time cost. The cost of a film is about 5-60 US dollars, and it can be provided within 1 hour! Time is efficiency, especially for production and processing enterprises, so chemical etching is more and more used in many industries!

Chemical Etching Service – China Chemical Etching Company

We offer Chemical Etching services for any type of Custom Chemical Etching parts, whether aluminum,stainless steel,brass,copper or titanium and more, simple or complex. Our precision Chemical Etching machines, combined with other advanced capabilities and our experienced team, can provide high-quality Chemical Etched parts and fast delivery.

We guarantee your Chemical Etching projects will be handled smoothly by our in-house Chemical Etching department and supplier network. As a result, you can focus on bringing your product to market. If you need a reliable Chemical Etching company, Be-cu.com will never let you down!

When looking for a quality Chemical Etching service, it is important to consider Be-cu’s capabilities. Be-cu has the latest technology and equipment to provide the highest quality services possible. Additionally, Be-cu offers a wide range of etch options to fit your specific needs. Below are some of the benefits of using Be-cu for your Chemical Etching needs:

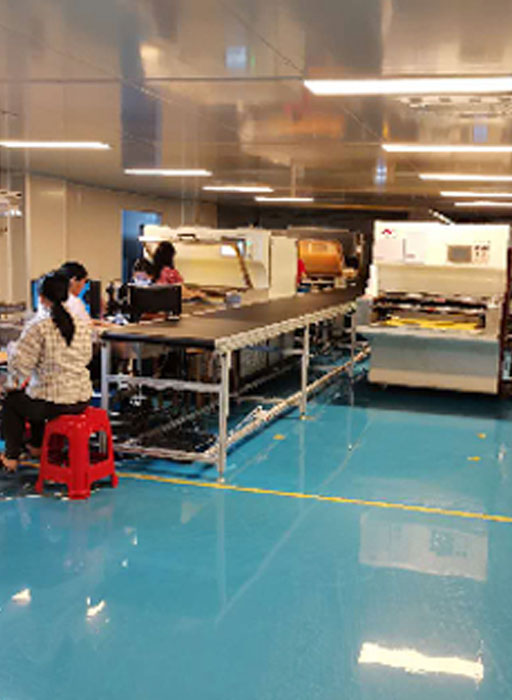

- Be-cu Prototype with 16 total automatic etching lines (10 horizontal and 6 vertical etching lines) which can deal with massive demand that request 700K piece per day as well as your individual customized small size requesting proceed by half automatic etching line.

- We have ful set of automatic production lines for cleaning, coating, development, etching and stripping etc with strong.

- Smallest line width 0.015mm, aperture 0.03mm with smallest tolerance as t 0.01mm can be fulfilled to meet your requirements

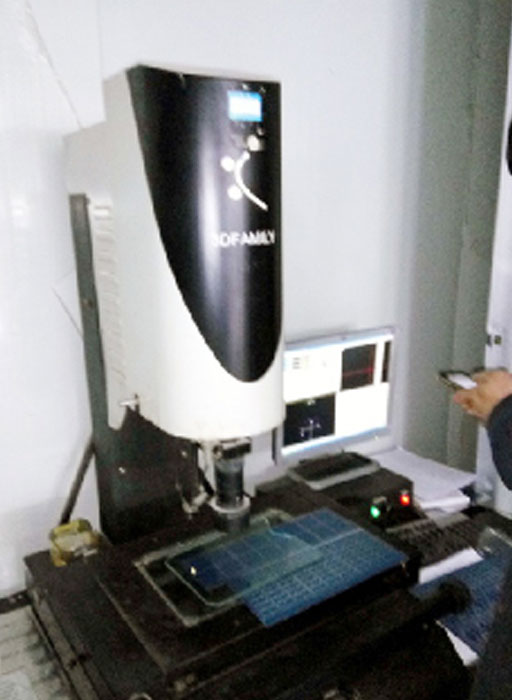

- Be-cu uses state-of-the-art digital imaging machines to precisely map designs onto the metal sheets and eliminate variations so production remains consistent – as do we.

With an ISO 9001:2015 certificated manufacturing factory, we provide material and full dimensional inspection reports as your request. You can always rest assured the parts you get from Be-cu.com will exceed your expectations.To use our online metal etching service, submit your design file for metal etching services and get instant metal etching quotes.

It has a factory building covering an area of 10,000 square meters, equipped with a 100,000-level dust-free workshop, 16 etching production lines, and more than 120 employees, which can greatly meet the production needs of customers.

Chemical Etching Process In BE-CU Prototype

Surface Finishing Options for Chemical Etching

Parts made using photo etching usually feature excellent finishes. At Be-cu.com, we offer various custom finishing options that boost the produced part’s functionality, appearance, and durability.

- BLACKENING SERVICES

- ELECTROPOLISHING

- PAINTING

- PASSIVATING

- REAMING

- TUMBLING

- CUSTOM PACKAGING

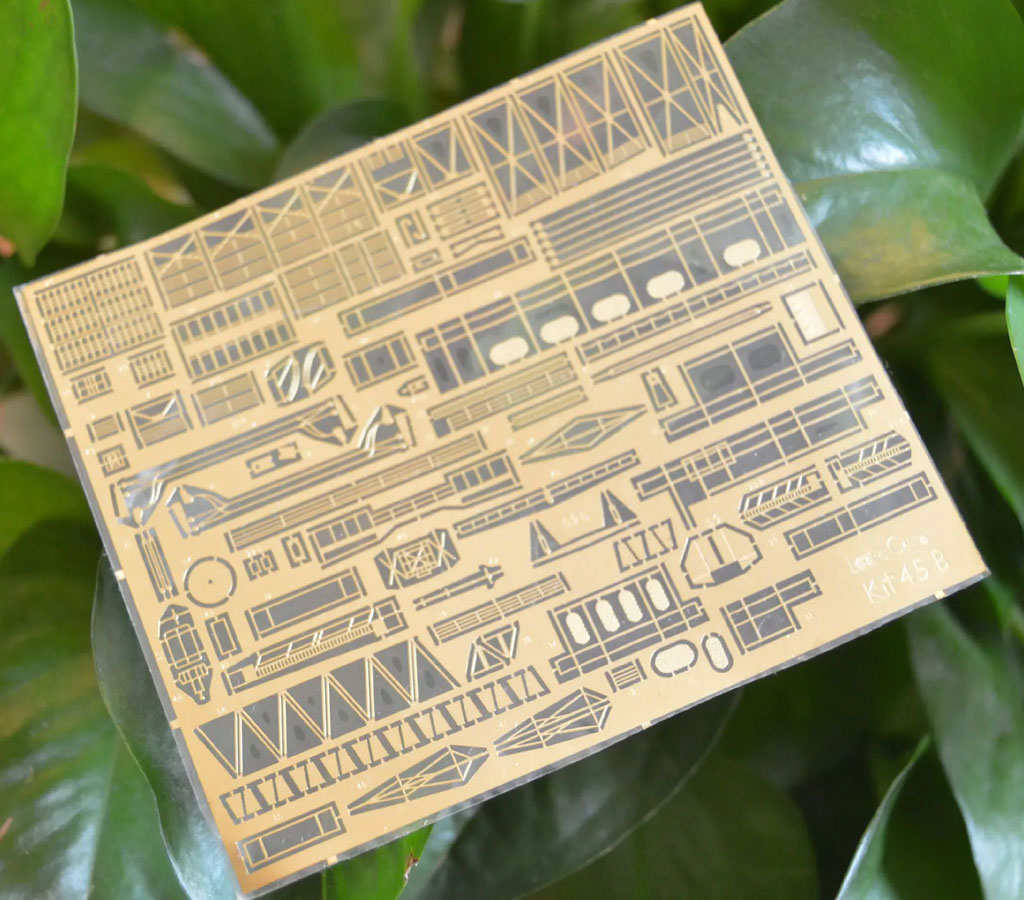

Precision Chemical Etching Parts & Case Studies In China

Because Be-cu is so specialized in metal manufacturing, we are the China Chemical Etching of choice. Be-cu.com has over 95,000 square feet of manufacturing space in three locations. Our unparalleled level of automation and our deep dedication to quality support our proud tradition of outstanding customer service. All Be-cu Chemical Etching facilities offer a wide variety of unique services and capabilities that allow us to produce the highest caliber of custom metal etching in both large and small quantities – quickly and competitively.Be-cu.com will make the difference in your project. Contact Be-cu at [email protected] or request a quote with our easy-to-use online form.

-

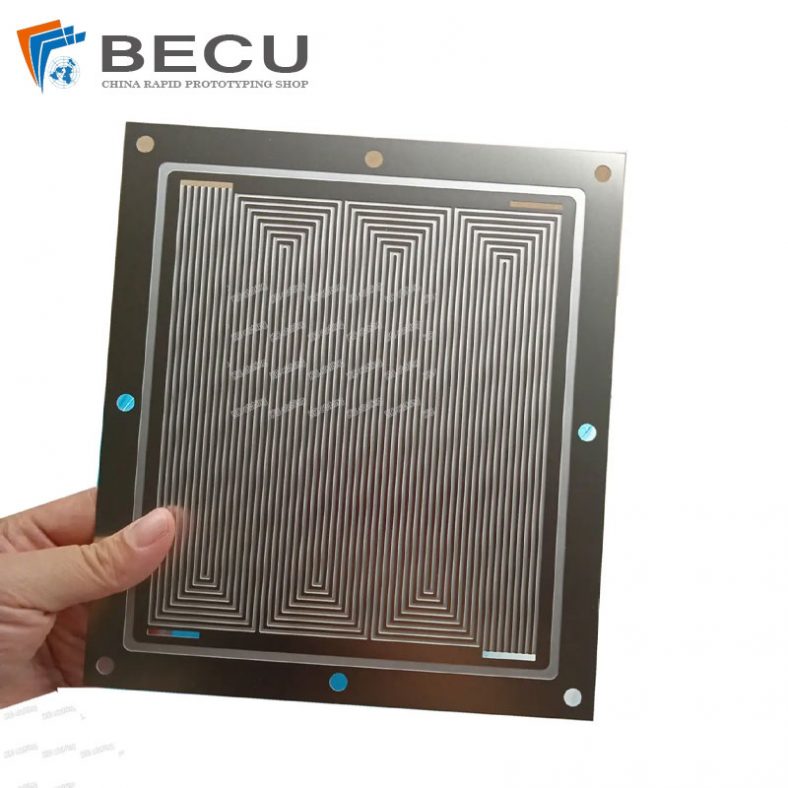

Metal Etched Hydrogen Fuel Cell Metal Bipolar Plates

-

Precise Etching Stainless Steel 316 High-Speed Hair Dryer Networks

-

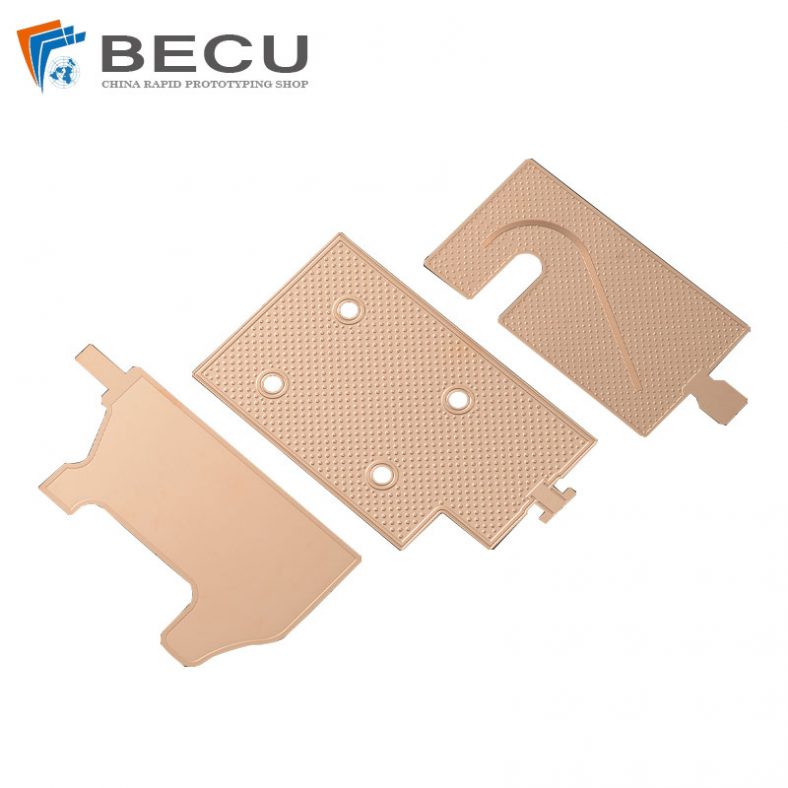

Etched VC Uniform Temperature Cooling Plate

-

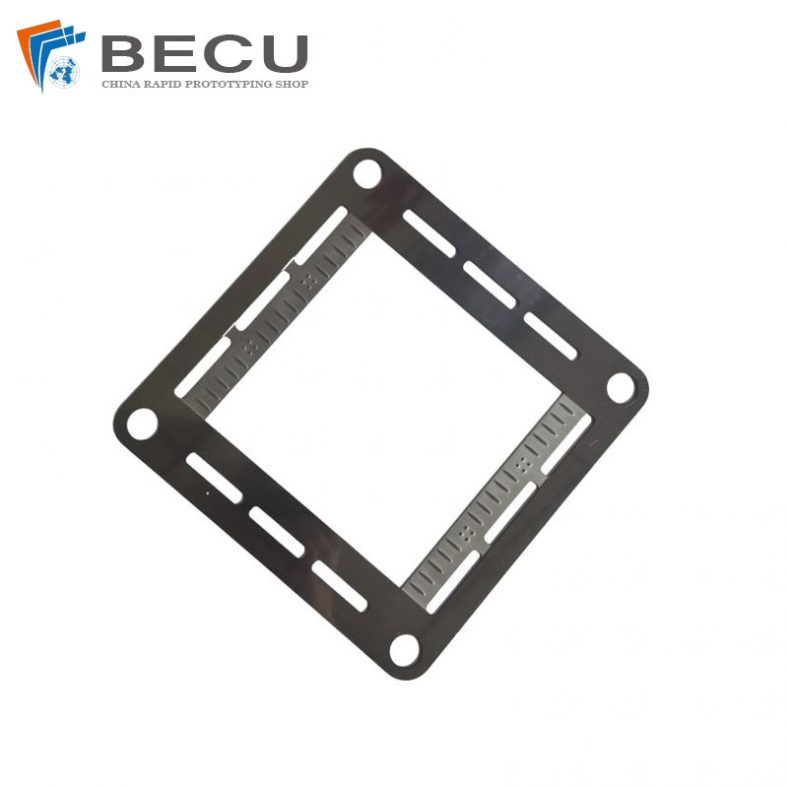

Etching LED EMC Packaging Bracket

-

Planar Etched Molybdenum Alloy Micro-Air Mesh

-

Chemical Etching Stainless Steel 316 Bipolar Flow Plates

-

Etching Low Resistivity Copper 110 Contact Rings

-

Hollow Laser Cutting Brass 360 Jewelry

-

Laser Cut And Etching 303 Jewelry Pendant

-

Precision Etching FeCrAl Resistor Sheet For Electronics Products

-

Photo Chemical Etching Microporous Dust Filter For Automotive Speaker

-

Precision Etching Automotive Audio Grille

Chemical Etching for Industrial Applications

Chemical Etching affords both machinists and industries extensive benefits—little wonder why it has become the go-to process for metal fabrication.Chemical Etching facilitates the high-precision production of prototypes and thin parts regardless of volume. Here are the industrial applications of Chemical Etching parts according to industries.

Be-cu’s etching services meet these needs by providing faster product turnaround without compromising quality so your products can reach consumers and their homes faster than your competition. Whether your needs include mass-produced samples or not, we’re up to the challenge. With Be-cu we can usually produce a prototype within 24 hours.

- 3C Products

- Medical Device Parts

- Pilotless Aircraft Parts

- Vehicle Parts

- Intelligent Component

- DIY Toys

- RF/Microwave

- Electronics (In the electronics industry, etching is used to produce a wide variety of products such as printed circuit boards, step templates, EMI/RF shielding, foil strain gauges)

- Signs, labels and nameplates (such as industrial nameplates and labels, souvenirs, hotel signs, elevator doors, trophies and trophies, wayfinding signs)