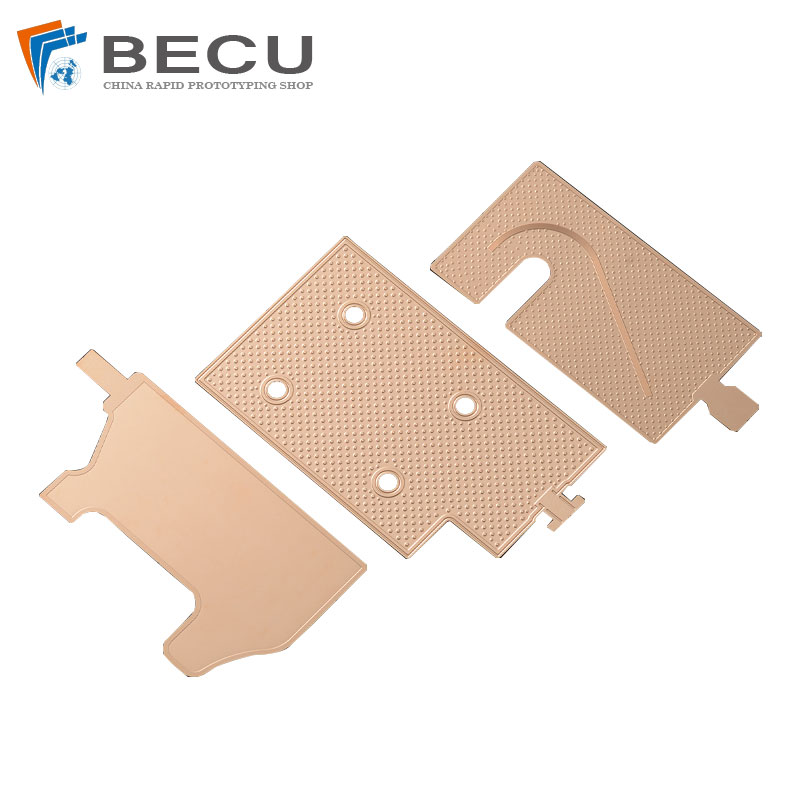

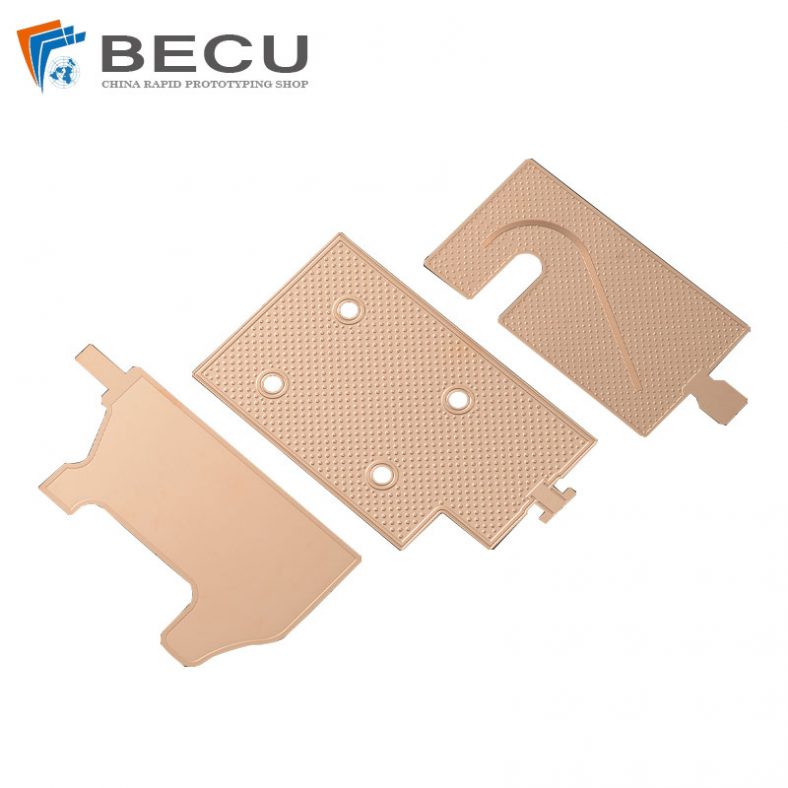

VC Cooling Plate

- Material: Copper

- Thickness: 0.01mm

- Project Offer:Within 3 hours

- Process: Precision Etching

- Custom Cycle:Involving Mold Opening, – monthly sample delivery

- Production Capacity:5000-10000PCS/day

- Application: Electronic

- Add Process:Stamping, Self-Owned Hardware Mold Room, Electroplating, Electrophoresis, PVD Vacuum Plating

- Type: Copper Etching

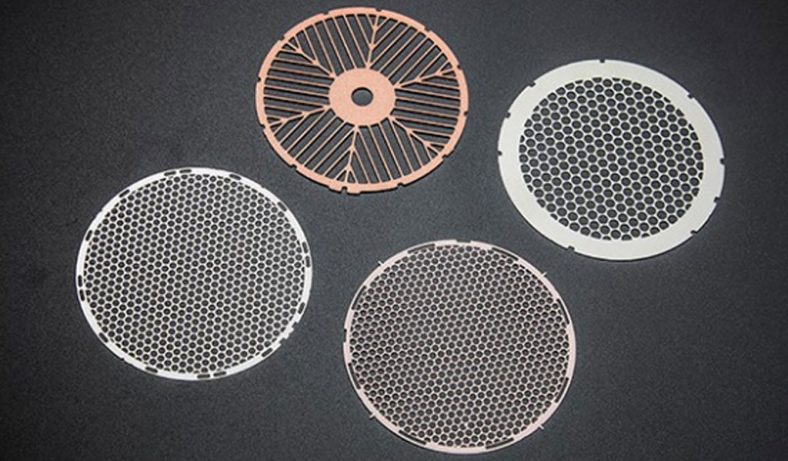

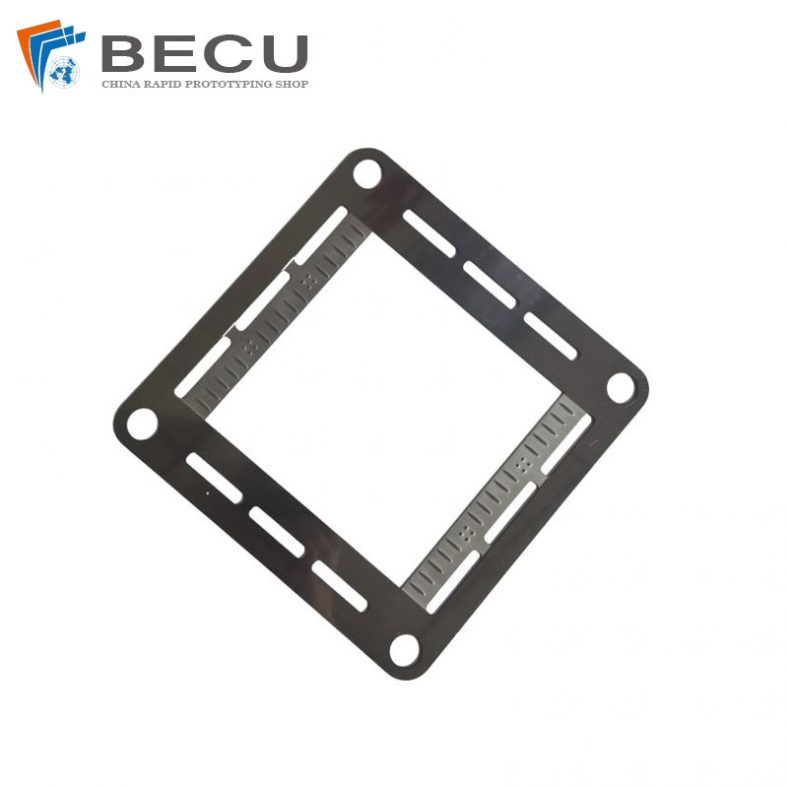

High-Quality Etched VC Uniform Temperature Cooling Plate

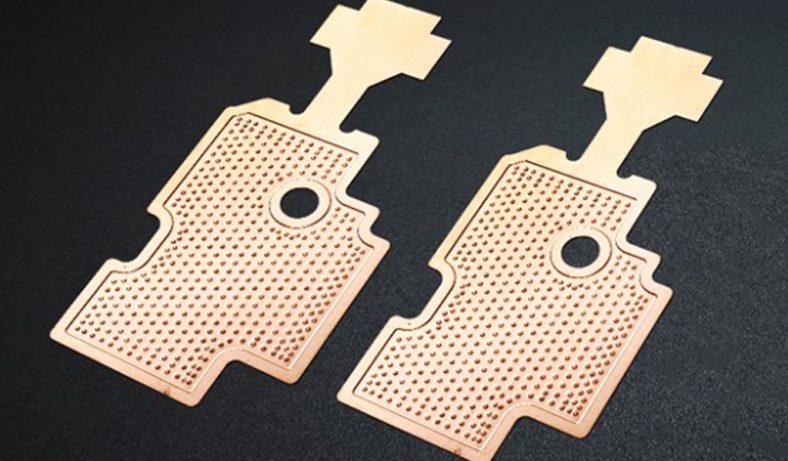

Metal etching is a subtractive manufacturing process used to create intricate designs, patterns, or markings on metal surfaces. It involves selectively removing material through chemical, mechanical, or electrochemical processes. Precision is crucial in metal etching, as even minor deviations can result in defects or inaccuracies in the final product.

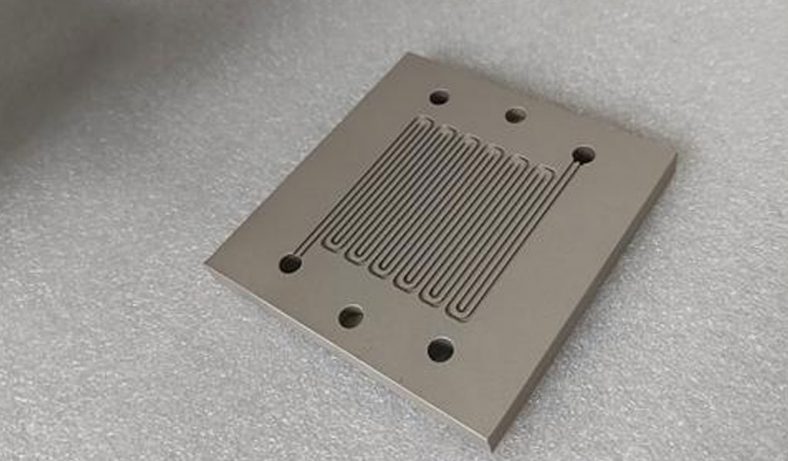

VC (Variable Conductance) uniform temperature cooling plates represent a significant advancement in temperature control technology for metal etching. Unlike conventional cooling plates that operate at fixed temperatures, VC cooling plates dynamically adjust their cooling capacity based on real-time temperature fluctuations. This adaptive feature allows them to maintain precise and uniform temperatures across the entire metal surface during the etching process.

As technology continues to advance, the role of VC uniform temperature cooling plates in metal etching is poised to expand further. Ongoing research and development efforts aim to enhance their capabilities, such as integrating smart sensors for real-time monitoring and implementing predictive maintenance algorithms to optimize performance and reliability

Why Choose Our Etched VC Uniform Temperature Cooling Plate Service?

- Etching processing technology is adopted, with high precision, up to ±0.008mm (different thickness of different materials). 15 years of professional precision etching processing factory, the quality is trustworthy.

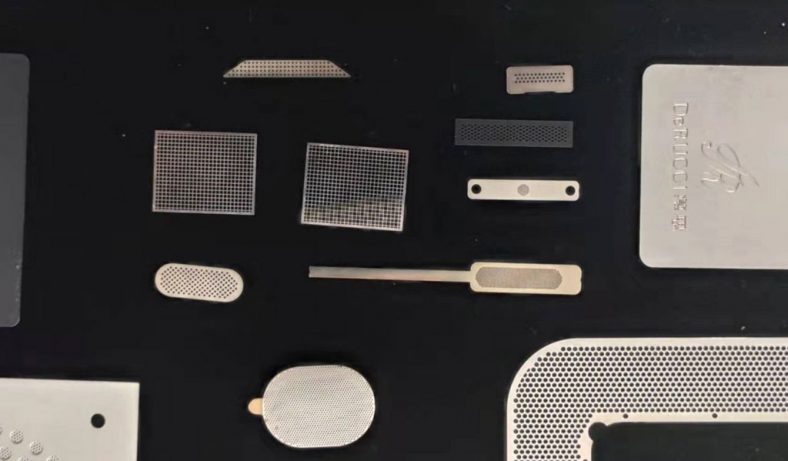

- The etching process of Be-cu has no restrictions on complex patterns and arbitrary geometric figures. No matter how complicated the hole shape or pattern is, it can be formed in one process without increasing the production cost.

- Be-cu chemical etching is a double-sided simultaneous processing technology. The surface of the product (front and back) is smooth, no bumps, no pits, no burrs, no warping, the mesh is flat and no deformation, no need to polish , Polishing, self-care process after flattening.

- The size of etching process is fine (aperture ≥ 0.1mm, thickness 0.03-2.0mm), and the positioning is accurate (minimum precision ± 0.008) uniform.

- The production cycle is short, the response is fast, and the design is easy to modify. The Be-cu professional etching technology engineering team has a total of 17 people and has senior technicians who have been in the industry for 15+ years.

- Be-cu samples are produced quickly, and samples can be produced within 1-2 working days (determined according to product requirements).

- Be-cu etching has 16 automatic etching production lines, with high etching processing output, which can meet your production orders for batch processing and etching customized microporous mesh.

- Be-cu provides auxiliary services such as stamping, welding, oil spraying, painting, electrophoresis, electroplating, electrolysis, passivation, polishing, stretching, wire drawing, silk screen LOGO, injection molding, etc., to meet the needs of different products and realize convenient and fast — One-stop processing service.

- Be-cu has passed the factory inspections of many well-known companies such as Gree, Joyoung, Xinbao, Xiaomi, Lake and American and German customers. The quality and delivery time are stable, and the customer satisfaction and employee satisfaction are high.

Contact Be Cu Now for your Custom Metal Etching, We are your best online Etching services choice!

Specifications of Etched VC Uniform Temperature Cooling Plate

| Material Type | Aluminium/Brass/Copper/Nitinol/Stainless steel/Titanium |

| Size | Customized |

| Min. Hole Dia. | Dia.≥1.2xT |

| Min. Pitch | D≥1.0xT |

| Tolerance | 0.003mm |

| Material Thickness | T≥0.03mm |

| Process | Etching/Plating/Stamping/Bending/Laser cuting |

| Surface Finish | PVD/Coating/Painting |

| Inspection | IPQC/AQL |

| Packing | Plastic Tray or Customized |

Metal Etching Material

The Detail Of BE-CU Metal Etching Company

BE-CU Etch has specialized in high precision etchingindustry for over 10 years and supporting globalleading metal etching service in electronics, semiconductor-re-lated, car, new energy sources, and other industrieswith reliable technology and service. Our productsinclude lead frame,IGBT, metal bipolar plate for bat-tery, speaker mesh/interior parts for cars,5G heatsink(VC etching) and high precision metal accesso-ries for notebooks/computer/hardware, etc.

BE-CU precision etching company has passed the certifications of ISO9001/14001,IATF16949,QCO80000, IEC27001.We provide one-stop solutionwith chemical etching, stamping and surface finish, which make us could offer high quality productwith excellent competitive price to our customers and help customers reduce the cost and pressure of supply chain management.