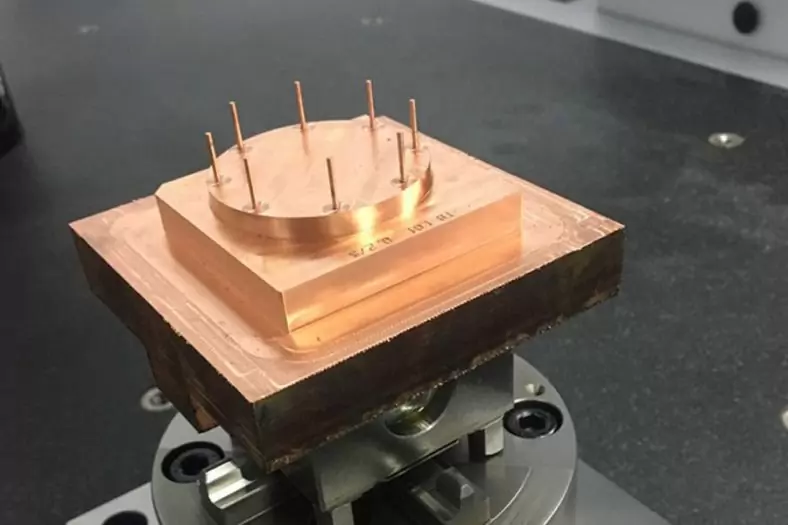

5 Axis Machining Brass Spare Parts

- No.: Brass

- Color: Custom

- Surface Treatment: Oxidation

- Product Material: Brass Alloy

- Proofing Cycle:7 days(100000 pcs/M)

- Application: Precision Cnc Machining

- machining Factory: Be-cu Rapid Prototyping Companies

- Product Category: Machinery

- Production Process: Brass 5 Axis Machining

- Size: According To Customer’s Drawings

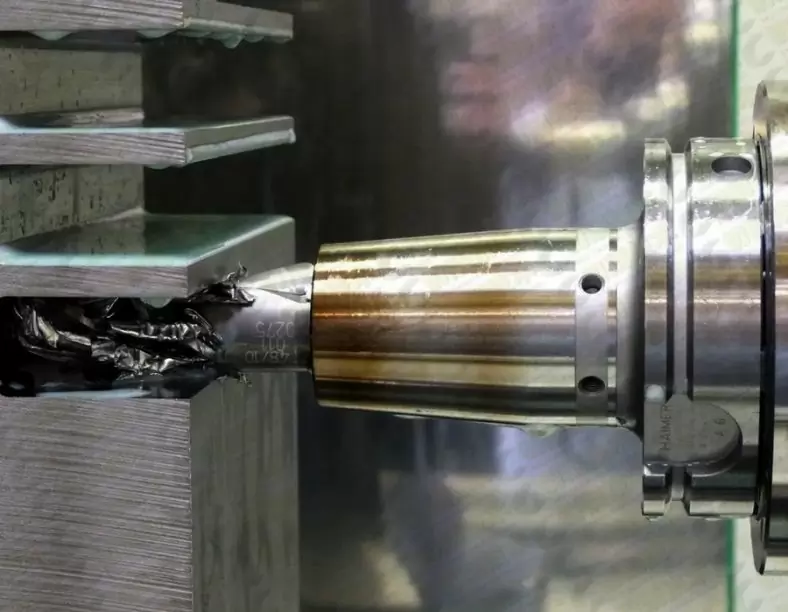

High-Quality 5 Axis Turn-Mill Machining Brass Parts

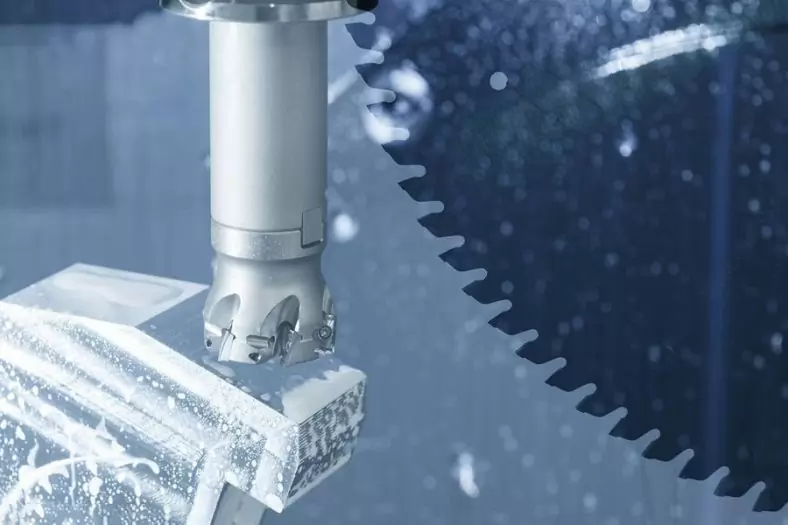

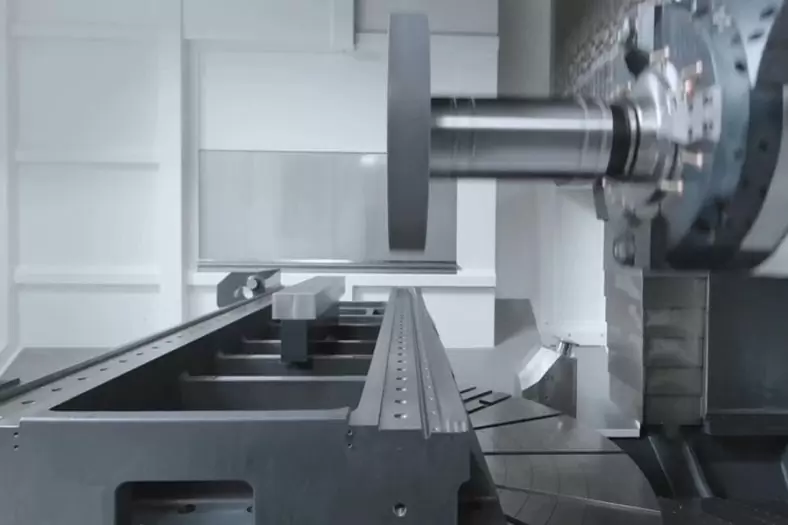

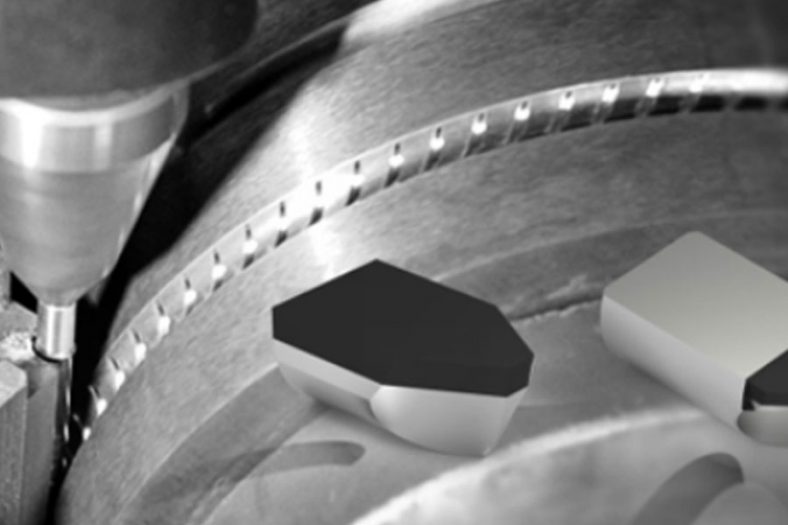

Custom manufacturer of 5 Axis Turn-Mill Machining Brass Parts for aerospace, defense, medical and space industries. Mechanical and electrical assembly, manufacturing, 3, 4 and 5-axis machining, milling, hard turning, bending, kitting, gun drilling, EDM, lapping, forming, welding, grinding heat treating, plating, coating, painting, priming, structural testing, and finishing services are available.

The Advantages Of 5 Axis Turn-Mill Machining Brass Parts

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of 5 Axis Turn-Mill Machining Brass Parts

| Material | Brass |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Milling, Drilling, 5 Axis Cnc Machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Machinery |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Cnc Milling Company

Looking for low cost CNC milling parts with unparalleled quality? BE-CU Prototype is a professional China CNC company provides superior precision CNC milling service with advanced machines including CMC milling center and milling machining centers from the general 3-axis to 5-axis and accomplished machinists. Our experienced operators proficient in CAD (computer-aided design) and CAM (computer-aided manufacturing) programs are always finding the best way to produce the highest quality CNC milled parts & components for clients. With strong capabilities and extensive experiences, we can provide top-grade but cost-effective custom CNC milling services from China including 3-axis CNC milling and 5-axis milling for high-speed CNC manufacturing, rapid prototyping, and precision CNC milling and turning. Our high-quality rapid CNC milling products are involved in the field of automation design, lockset, automobile parts machining, machinery milling, defense industry, medical equipment, lighting parts machining, etc.