Cnc Machining Grey Cast Iron Services In China

As a leading name in precision manufacturing and Grey Cast Iron exceptional CNC machining services, we take pride in delivering cutting-edge solutions that meet the diverse needs of our clients across industries.

In today’s competitive landscape, the demand for high-quality, efficiently produced components has never been greater. It is with this understanding that we have invested significantly in state-of-the-art CNC machining capabilities, combined with our expertise in working with Grey Cast Iron. Our CNC machining services are geared towards achieving unparalleled precision in the manufacturing process. The controlled environment, automated tools, and computer-guided operations ensure that each component meets exact specifications down to the micron level. Grey Cast Iron, with its favorable machining characteristics, further complements our commitment to precision, enabling us to produce intricate parts with utmost accuracy.

At Be-Cu prototype, we understand that each project is unique. Our Grey Cast Iron CNC machining services offer a high degree of versatility, allowing us to cater to various industries and applications. Whether you require components for automotive, aerospace, machinery, or any other sector, our team of skilled engineers can customize solutions to fit your precise requirements.

Time-to-market is crucial in today’s fast-paced business environment. Our CNC machining processes are optimized for efficiency, ensuring that your projects move seamlessly from design to finished product. The inherent machinability of Grey Cast Iron allows us to reduce setup times and minimize lead times, without compromising on quality.

Grey Cast Iron – Machinability

Gray cast iron is known for its excellent machinability due to its unique microstructure and composition. The graphite flakes in gray cast iron act as built-in solid lubricants, providing natural chip-breaking properties and reducing tool wear. Here are chart about the machinability of gray cast iron:

| Property | GG10 | GG20 | GG25 | GG30 | GG35 | GG40 |

|---|---|---|---|---|---|---|

| Density | 6.9 – 7.1 | 6.9 – 7.1 | 6.9 – 7.2 | 6.9 – 7.2 | 6.9 – 7.2 | 6.9 – 7.3 |

| Young’s Modulus | 100 – 120 | 100 – 120 | 110 – 130 | 120 – 140 | 130 – 150 | 140 – 170 |

| Tensile Strength | 100 – 150 | 150 – 200 | 180 – 230 | 200 – 250 | 220 – 270 | 250 – 300 |

| Compressive Strength | 300 – 400 | 400 – 500 | 450 – 550 | 500 – 600 | 550 – 650 | 600 – 700 |

| Shear Strength | 60 – 70 | 70 – 80 | 80 – 90 | 90 – 100 | 100 – 110 | 110 – 120 |

| Hardness (Brinell) | 90 – 110 | 110 – 130 | 130 – 150 | 150 – 170 | 170 – 190 | 190 – 210 |

| Thermal Conductivity | 45 – 55 | 45 – 55 | 50 – 60 | 55 – 65 | 60 – 70 | 65 – 75 |

| Coefficient of Thermal Expansion | 10 – 12 | 10 – 12 | 10 – 12 | 10 – 12 | 10 – 12 | 10 – 12 |

| Melting Point | 1140 – 1250 | 1140 – 1250 | 1140 – 1250 | 1140 – 1250 | 1140 – 1250 | 1140 – 1250 |

| Poisson’s Ratio | 0.25 – 0.28 | 0.25 – 0.28 | 0.25 – 0.28 | 0.25 – 0.28 | 0.25 – 0.28 | 0.25 – 0.28 |

Why Choose Our Grey Cast Iron Cnc Machining Service?

- Save time and money for your Grey Cast Iron project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of Grey Cast Iron materials can be machined

- Custom complex Cast Iron cnc machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

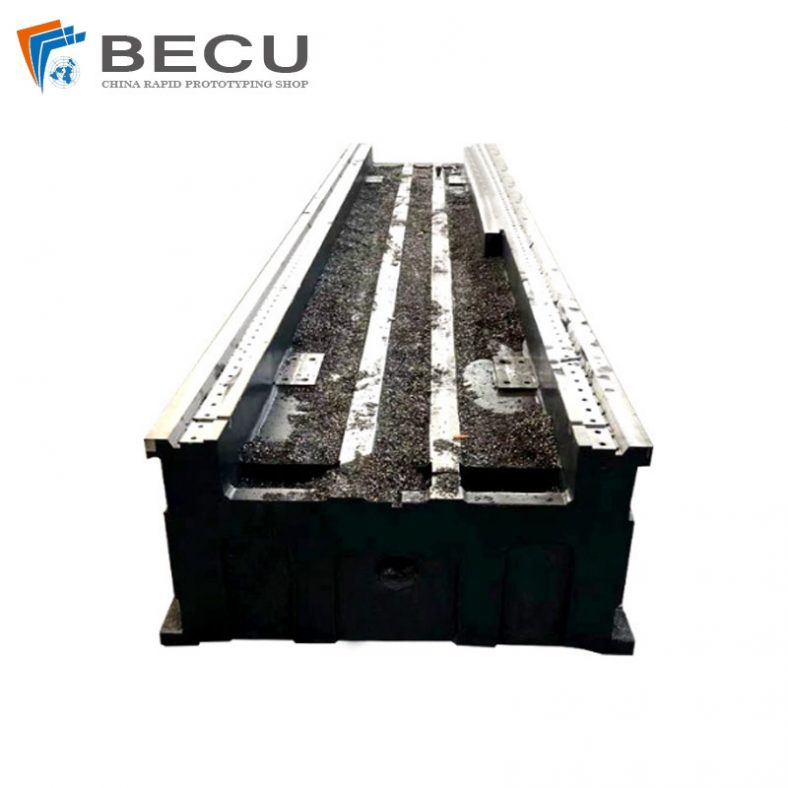

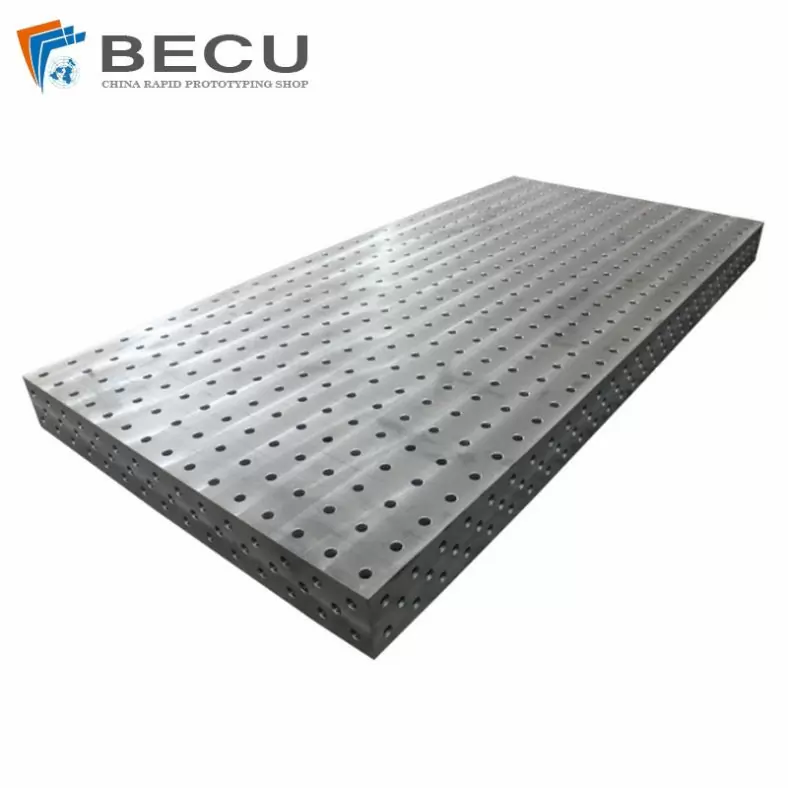

Top Grey Cast Iron Machined Parts & Case Studies

Cnc Machining processes such as cnc milling, turning and Gantry mill machining are today considered the most economic way to make Cast Iron prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes sand casting is the only option. Our company has rich experience making Cast Iron concept models and precise functional components. Understanding the properties of different Cast Iron alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on Cast Iron alloy. Be-cu prototyping company provides a range of solutions for the machining of Cast Iron parts.