What Is Cast Iron

Cast iron is a type of iron-carbon alloy that is known for its high carbon content and distinctive properties. It is created by melting iron and adding a significant amount of carbon, typically around 2 to 4 percent by weight. This high carbon content gives cast iron its unique characteristics, including its strength, durability, and heat retention capabilities.Cast iron’s properties make it suitable for various applications, ranging from industrial machinery and engine components to cookware and decorative items. However, it’s important to note that cast iron is prone to rust if not properly cared for, as it contains iron which can oxidize in the presence of moisture and oxygen. To prevent rusting, cast iron items are often coated with enamel or seasoning, a layer of oil or fat that helps protect the surface.

Benefits Of Cast Iron Material (CNC Cast Iron Parts)

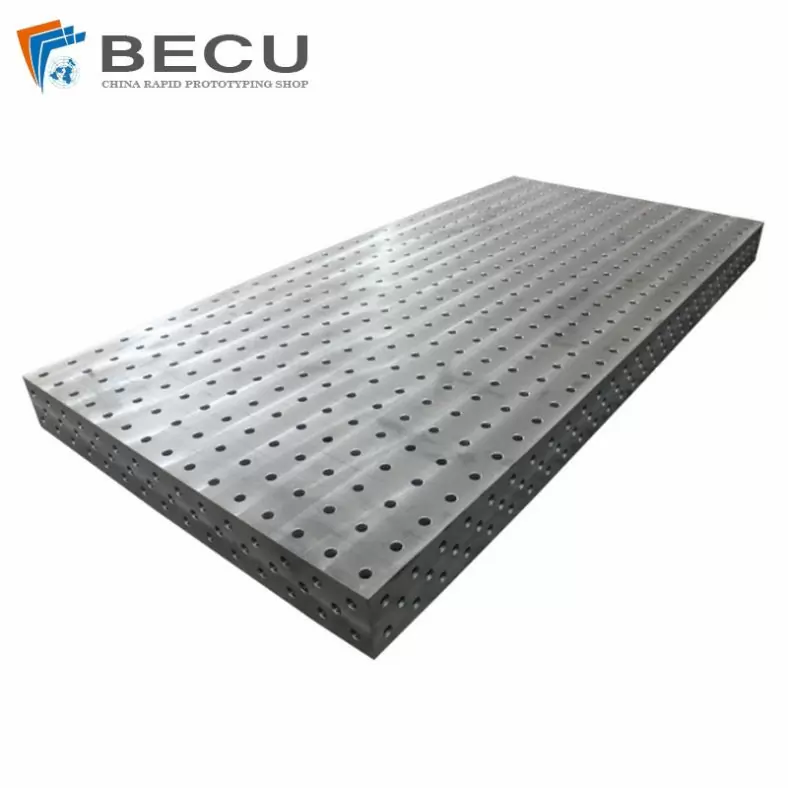

- Strength and Durability: Cast iron is known for its exceptional strength and durability. It can withstand heavy loads, high impact forces, and mechanical stresses, making it suitable for applications that require components with long service lives.

- Wear Resistance: Cast iron exhibits excellent wear resistance due to its hardness and ability to form a protective surface layer. This property is especially beneficial in applications where components experience friction, abrasion, or sliding contact.

- Cost-Effectiveness: Cast iron is often more cost-effective than some other metals with similar properties, making it a practical choice for various applications where strength and durability are essential.

- Vibration Damping: Cast iron has inherent damping properties that help absorb vibrations and reduce noise. This property is valuable in applications where minimizing vibrations is important for precision, such as in machining and industrial equipment.

- Machinability: Despite its hardness, certain types of cast iron are relatively easy to machine, making them suitable for CNC machining processes. With the right tools and techniques, cast iron parts can be accurately shaped and finished to tight tolerances.

- Versatility: Cast iron is used in a wide range of industries and applications. It can be found in automotive components, engine blocks, pump housings, hydraulic components, industrial machinery, cookware, and decorative items.

- Corrosion Resistance: Some cast iron types, particularly those with protective coatings or surface treatments, exhibit good corrosion resistance. This makes them suitable for applications exposed to moisture or corrosive environments.

- Recyclability: Cast iron is a recyclable material, contributing to sustainability efforts by reducing the demand for new raw materials.

- Design Flexibility: Cast iron can be cast into intricate shapes and complex geometries, allowing for creative and efficient designs of components. This design flexibility is valuable for achieving optimized structures and efficient manufacturing processes.

- Heat Retention and Dissipation: Cast iron has a high thermal mass, allowing it to retain and distribute heat effectively. This makes it suitable for applications where temperature stability or heat dissipation is crucial, such as in engine components, cookware, and industrial machinery.

CNC Cast Iron Machining

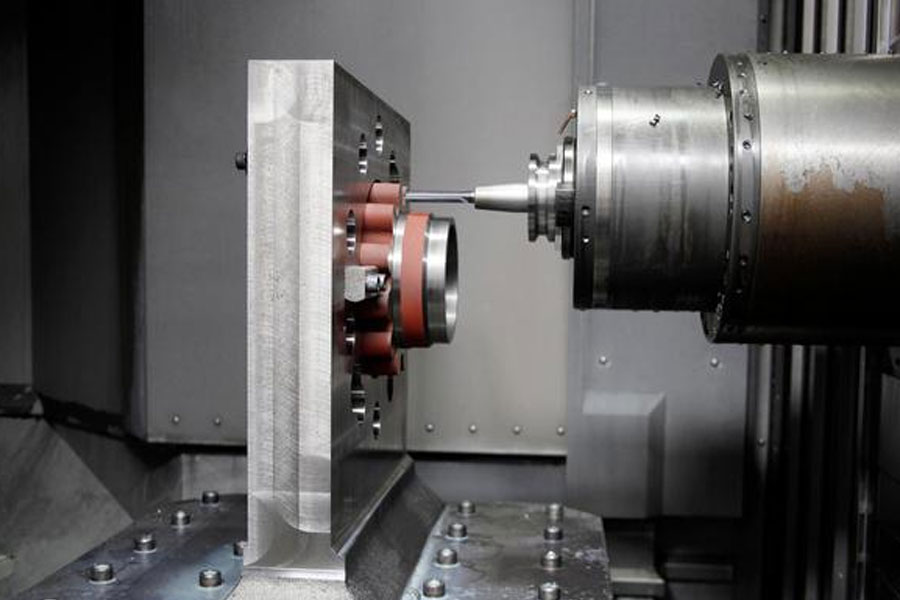

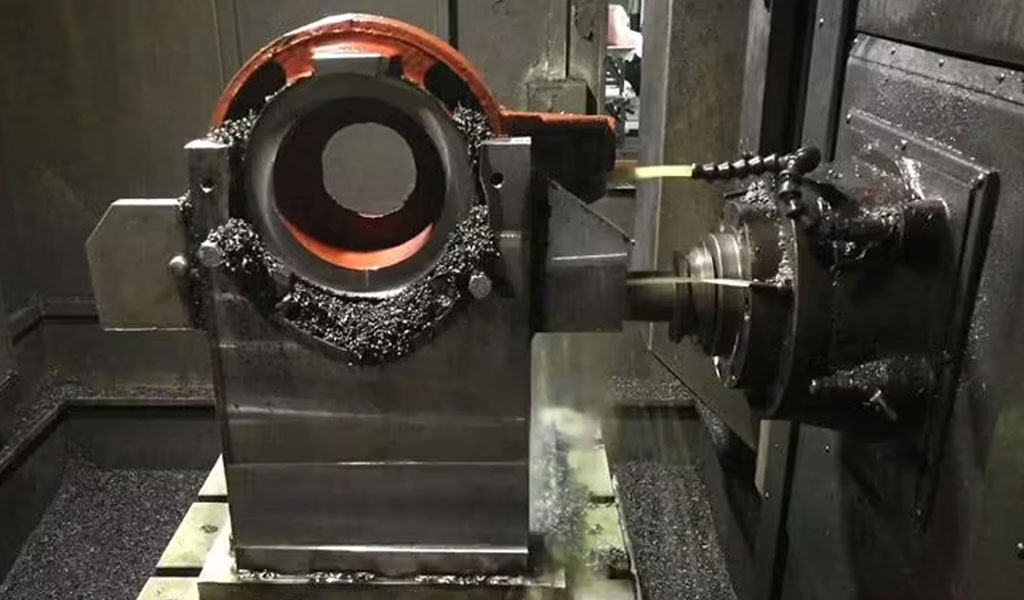

CNC cast iron machining refers to the process of using computer numerical control (CNC) technology to shape, cut, and manipulate cast iron workpieces with precision and accuracy. Cast iron is a challenging material to machine due to its hardness, abrasiveness, and potential for rapid tool wear.

CNC machining provides a solution by utilizing computer-controlled machinery to execute machining operations according to programmed instructions.

Machining Cast Iron – Custom CNC Machining Iron Manufacturer

In the world of modern manufacturing, precision and efficiency are paramount, driving the demand for advanced machining techniques that can handle even the most challenging materials. Cast iron, with its inherent hardness, abrasiveness, and unique characteristics, stands as one such material that requires specialized expertise to be transformed into intricately designed components. This is where our CNC Machining Cast Iron Service comes to the forefront.If you are seeking a professional Large CNC machining supplier to provide high quality precision CNC machined cast iron parts, Be-Cu prototype is one of the most affordable and capable manufacturer, specializing in Cast Iron CNC Machining process on advanced high speed 3-axis and 5 axis CNC machines.

At Be-Cu.com, we understand the intricate art of shaping cast iron into finely crafted components that meet the most stringent quality standards. Our state-of-the-art CNC machining facility, coupled with a team of skilled technicians, brings forth a comprehensive solution that merges cutting-edge technology with the age-old strength of cast iron. From automotive parts to industrial machinery components, our service is tailored to cater to diverse industries seeking precision, reliability, and a superior finish.

In this era of relentless innovation, our CNC Machining Cast Iron Service stands as a testament to the fusion of tradition and advancement. With a deep-rooted understanding of cast iron’s unique properties, we have honed our machining processes to deliver consistent results, regardless of complexity or scale. Our commitment to pushing the boundaries of possibility while adhering to the principles of quality and accuracy positions us as a partner of choice for those who seek not just components, but works of engineering excellence.

Join us in exploring the seamless synergy between cast iron’s inherent strength and the finesse of CNC machining. Whether you’re in need of intricate prototypes or large-scale production runs, Be-Cu is here to redefine possibilities and shape the future of CNC Machining for Cast Iron.

Advantages Of Cast Iron Machining

- Great precision and high tolerance ensure high-quality cast iron parts

- Time and cost-saving, great speed of Machining Cast Iron part

- Allows products ordered to be made precisely to the specifications stated

- Complex cast iron parts for high tech industry can be machined

Why Choose Our Cast Iron Cnc Machining Service?

- Save time and money for your Cast Iron project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of Cast Iron grades and alloy materials can be machined

- Custom complex Cast Iron machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

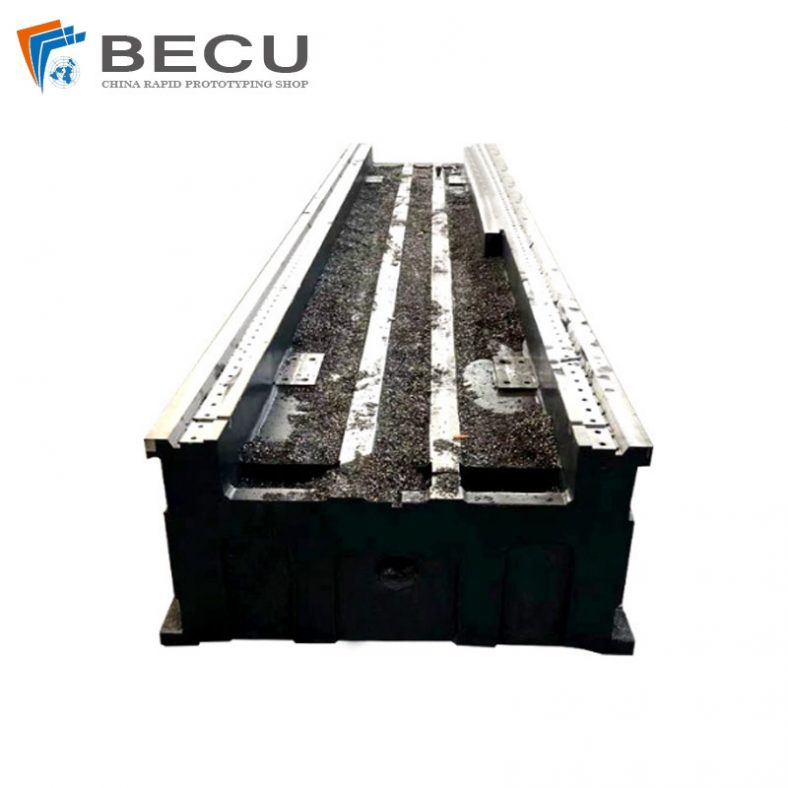

Top Cast Iron Cnc Machining Case Studies

Cnc Machining processes such as cnc milling, turning and Gantry mill machining are today considered the most economic way to make Cast Iron prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes sand casting is the only option. Our company has rich experience making Cast Iron concept models and precise functional components. Understanding the properties of different Cast Iron alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on Cast Iron alloy. Be-cu prototyping company provides a range of solutions for the machining of Cast Iron parts.