Cnc Machining Beryllium Copper C17200

Beryllium Copper C17200, also known as Alloy 25, is a high-strength copper alloy that contains a small percentage of beryllium as an alloying element. It belongs to the copper beryllium family of alloys, which are known for their excellent combination of mechanical, electrical, and thermal properties.

The composition of Beryllium Copper C17200 typically consists of approximately 1.8-2.0% beryllium and around 0.2-0.6% cobalt, with the remainder being copper along with small amounts of other elements such as nickel, iron, and lead. The addition of beryllium to copper imparts unique properties to the alloy, including high strength, excellent electrical conductivity, good thermal conductivity, and resistance to corrosion, wear, and fatigue.

Beryllium Copper C17200 Machining

CNC machining Beryllium Copper C17200 is a process of using computer numerical control (CNC) machines to shape and create parts from Beryllium Copper C17200 material. Beryllium Copper C17200, also known as Alloy 25, is a high-strength copper alloy that contains a small amount of beryllium and exhibits excellent electrical and thermal conductivity, high strength, and good corrosion resistance.Beryllium Copper C17200 is a relatively tough material that requires stable and rigid machining setups. Be-Cu Machinist Ensure that the CNC machine and its fixtures are properly aligned and tightened to minimize vibrations and maintain dimensional accuracy.

The Benefit Of Machined C17200

Beryllium Copper C17200 alloy offers excellent wear resistance and fatigue strength, allowing it to withstand repeated mechanical stresses and resist surface damage. This property is advantageous in applications where components are subjected to high wear or cyclic loading.Beryllium Copper C17200 maintains dimensional stability during machining, which is important for achieving tight tolerances and precise parts. It has low coefficients of thermal expansion, reducing the risk of dimensional changes due to temperature variations.

Make Machined C17200 With Be-cu

There are also a wealth of other mechanical and chemical finishing processes, so it’s a good idea to evaluate all of your options when designing a beryllium copper C17200 machined part. Choosing an expert CNC copper machining partner, like Be-cu.com, is critical in ensuring your parts are well machined and delivered on time to your specifications.Be-cu Prototype is a popular name in the beryllium copper machining industry and a leading provider of precision machining services across the globe.

Backed by over 20 years of professional experience, we’ve helped many innovative companies create beryllium copper C17200 components accurately while meeting their surface finish, precision, and tight tolerance requirements. You can learn more about our copper and copper alloy CNC machining capabilities on our site. And if you’ve already got your design, contact us and send drawings today!

The Industries & Applications Of Machining Beryllium C17200

- Electrical Connectors and Contacts: Beryllium Copper C17200 exhibits excellent electrical conductivity, which makes it well-suited for electrical connectors and contacts. It is used in high-current applications such as connectors for power transmission, electrical switches, and circuit breakers.

- Springs and Fasteners: The high strength and good spring properties of Beryllium Copper C17200 make it suitable for springs and fasteners that require resistance to fatigue and corrosion. It is commonly used in industries such as aerospace, automotive, and electronics.

- Conductive Springs and Contacts in Electronics: Beryllium Copper C17200 is widely used in the electronics industry for applications such as spring contacts in connectors, probe needles, and switches. Its combination of high electrical conductivity and mechanical properties allows for reliable electrical connections.

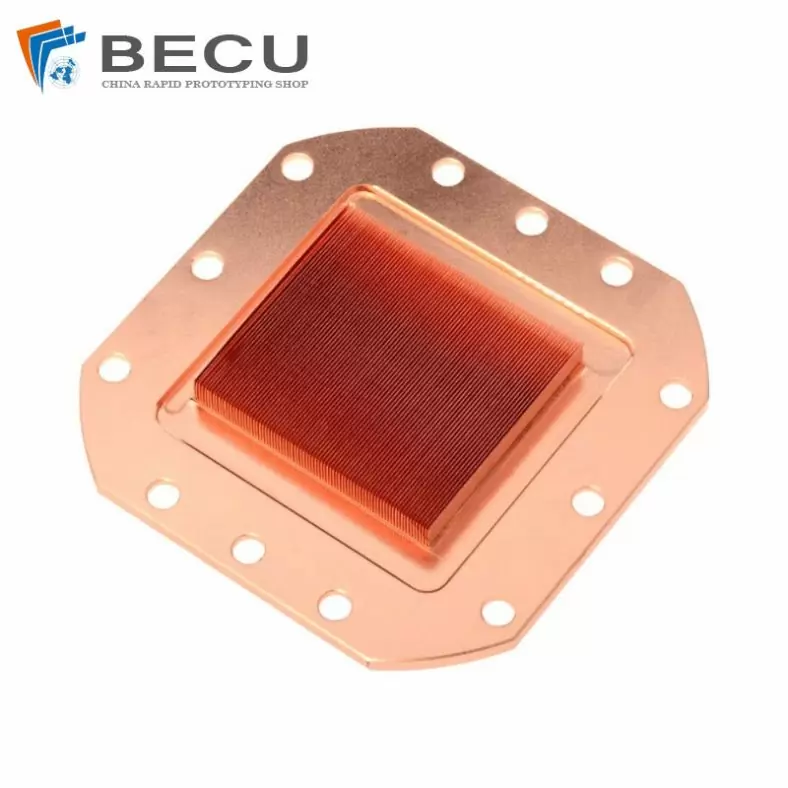

- Heat Sinks: Due to its excellent thermal conductivity, Beryllium Copper C17200 is used in heat sink applications where efficient heat dissipation is required. Heat sinks made from this material are commonly used in electronic devices, power modules, and high-power LED lighting.

- Welding Electrodes and Tips: Beryllium Copper C17200 is used in welding applications where resistance to heat, electrical conductivity, and durability are important. It is commonly used for welding electrode tips, spot welding electrodes, and resistance welding components.

- Bearings and Bushings: Beryllium Copper C17200 offers good wear resistance, high strength, and low friction characteristics, making it suitable for bearing and bushing applications. It is commonly used in industries such as aerospace, automotive, and oil and gas.

- Aerospace Applications: Beryllium Copper C17200 is utilized in various aerospace components, including connectors, electrical contacts, springs, and fasteners. Its combination of high strength, electrical conductivity, and corrosion resistance make it suitable for demanding aerospace environments.

Why Choose Our C17200 Cnc Machining Service?

- Save time and money for your beryllium copper C17200 project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of copper grades and alloy materials can be machined

- Custom complex copper cnc machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Beryllium Copper C17200 Machined Parts & Case Studies

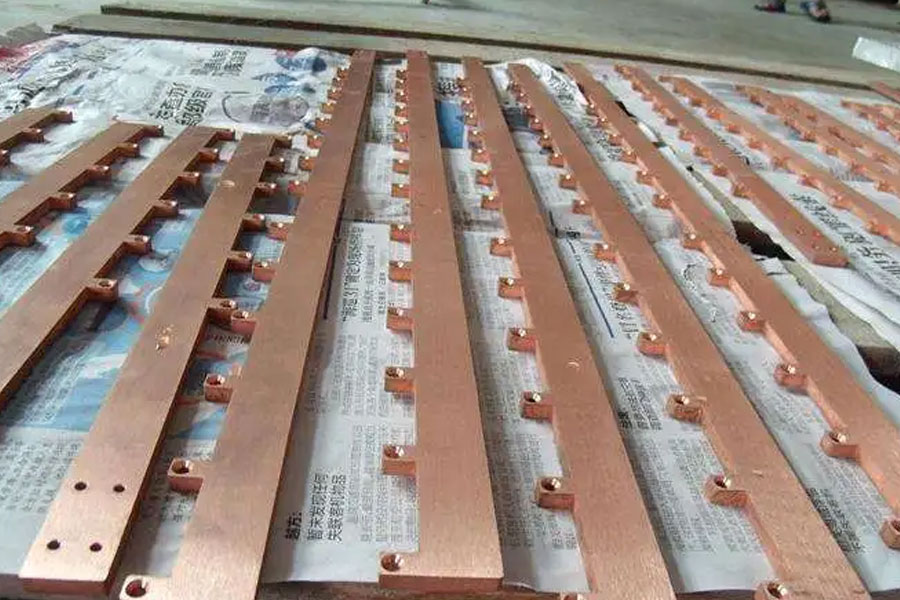

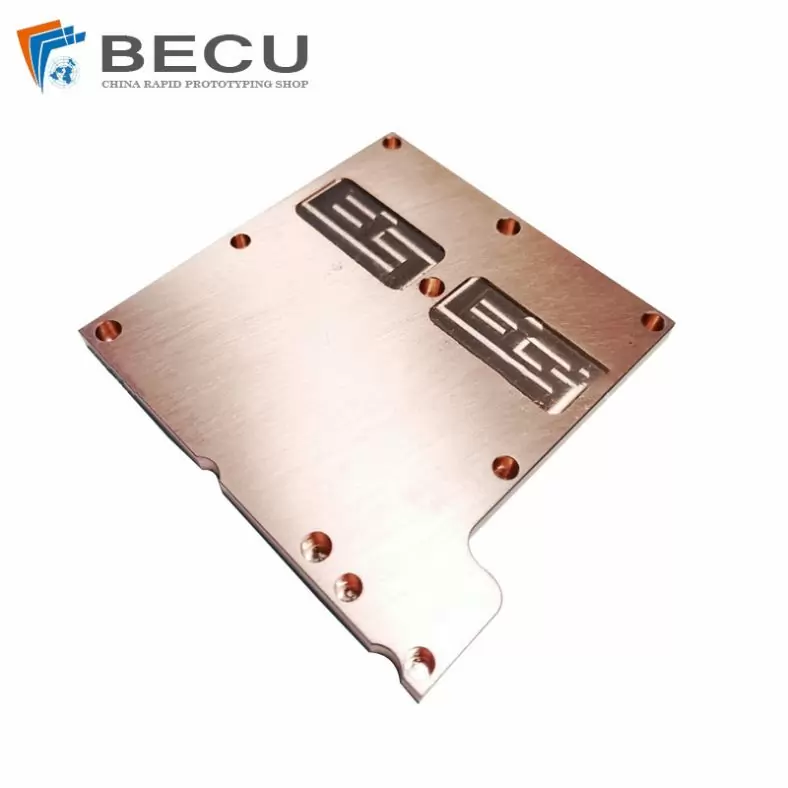

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make beryllium copper C17200 prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes sheet metal manufacturing is the only option. Our company has rich experience making beryllium copper concept models and precise functional components. Understanding the properties of different copper alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on copper alloy. Be-cu prototyping company provides a range of solutions for the machining of copper parts.

-

CNC Turning-Milling Machining Copper Facial Massage Roller

-

Precision Wire Cutting Plastic Injection Mould Core

-

Custom Machining Copper Water Cooling Heat Sink

-

Cnc Carved Machining And Wire Cutting Copper Electrode

-

CNC Milling Automotive Audio Amplifier Base

-

Precision Machining Heatsink Spacer Substrate

-

Precision Turning T3 Copper Machinery Parts By Polishing

-

Precision Milling Machining Chrome-Plated Copper Spare Parts

-

Precision CNC Turning N9 Copper Parts

-

Swiss Turning Gold-Plated T2 Copper Parts

-

Precision Machined Copper Die Casting Parts

-

CNC Turning New Energy Vehicle Copper Connector

Online Cooperate With Beryllium Copper C17200 Machining Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision cnc machining and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.