Cnc Machining Monel K500

Monel K500 is a high-performance nickel-copper alloy known for its exceptional mechanical properties, including high strength, corrosion resistance, and durability.

Monel k500 alloy is a member of the Monel family of alloys, which were first developed in the early 20th century. Monel alloys, including K500, are widely used in demanding applications where traditional materials fail to perform.

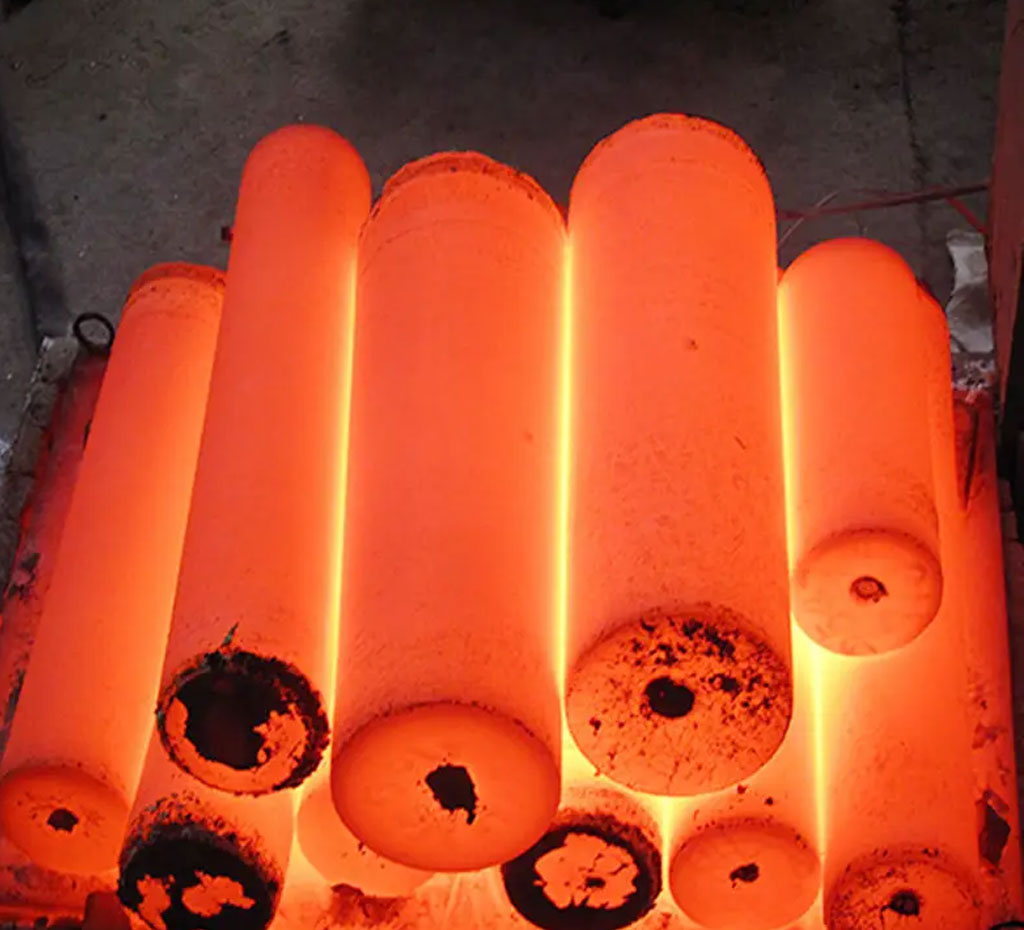

High Temperature Compression Test Of K500

Monel K-500 alloy is a material known for its exceptional corrosion resistance and high-temperature performance, making it widely used in aerospace, aviation, petroleum, and chemical industries.

To better understand the thermal deformation behavior and microstructure evolution of Monel K-500 alloy, researchers conducted aging treatment on Monel K-500 alloy samples to precipitate a significant amount of carbides. The samples were then subjected to high-temperature compression tests using the Gleeble-3800 thermal simulation machine.

During the tests, the deformation temperatures were set at 850℃ and 1050℃, and the strain rate was set at 0.01 s⁻¹. Optical microscopy was used to analyze the microstructure of the compressed samples, determining the “safe zone” and “instability zone” for alloy compression deformation. The test results showed that at a deformation temperature of 850℃ and a strain rate of 0.1 s⁻¹, dynamic recrystallization of the alloy began, and the thermal deformation activation energy of the alloy was 375.32611 kJ/mol.

Based on the test data, the thermal compression constitutive equation of Monel K-500 alloy and the thermal processing map for a true strain of 0.8 were established. By analyzing the thermal processing map, the reasonable thermal processing parameters were found to be a strain rate of 0.1-0.5 s⁻¹ and a deformation temperature of 1000℃-1050℃. At this time, the dissipation power was around 40%, recrystallization was sufficient, and the microstructure was fine and uniform.

Monel K-500 alloy exhibits good thermal deformation behavior and microstructural properties under appropriate thermal processing parameters. In practical production, optimizing thermal processing parameters can improve the microstructure and mechanical properties of Monel K-500 alloy, providing theoretical basis and technical support for its further widespread application.

Composition and Properties of Monel K500

- Chemical Composition : Monel K500 is primarily composed of nickel (63-70%) and copper (27-33%), with significant amounts of aluminum (2.3-3.15%) and titanium (0.35-0.85%). The alloy also contains small quantities of iron, manganese, silicon, and carbon. This unique combination of elements imparts Monel K500 with its exceptional mechanical properties and corrosion resistance.

- Mechanical Properties : Monel K500 exhibits high tensile strength, typically ranging from 900 MPa to 1100 MPa. It has excellent toughness and maintains its mechanical properties over a wide temperature range. The alloy’s yield strength is also notable, making it suitable for high-stress applications.

- Corrosion Resistance : One of the standout features of Monel K500 is its superior corrosion resistance. The alloy is highly resistant to seawater and steam at high temperatures, as well as to salt and caustic solutions. This makes it an ideal choice for marine and chemical processing applications.

Computer Numerical Control (CNC) machining is a precise and automated manufacturing process used to create complex parts from various materials, including metals, plastics, and composites. CNC machining has revolutionized the manufacturing industry by providing high accuracy, repeatability, and efficiency.

CNC machining Monel K500 presents unique challenges due to the material’s toughness and work-hardening characteristics. However, with the appropriate tools, techniques, and parameters, it is possible to achieve high-quality machined parts that meet stringent industry standards.

Machining Monel K500 – CNC K500 Machining Company

BE-CU has years of experience CNC machining monel K500 components. Our monel experience leads to the machining of larger sized workpieces. We have the capability to machine large monel ring (up to 26” diameter) and monel shafts(main usd for oil and gas industries).

Monel K500 is a difficult metal to machine using traditional cold forming techniques due to rapid work hardening. After the first machining pass, work hardening tends to plastically deform either the workpiece or the tool on subsequent passes. For this reason, our skilled technicians machine age-hardened monel K500 using an aggressive but slow cut with a hard tool, minimizing the number of passes required.

Backed by over 30 years of professional experience, we’ve helped many innovative companies create Monel K500 components accurately while meeting their surface finish, precision, and tight tolerance requirements. You can learn more about our super alloys and monel alloy CNC machining capabilities on our site. And if you’ve already got your design, contact us and send drawings today!

Why Choose Our K500 Cnc Machining Service?

- Save time and money for your Monel K500 project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of monel grades and alloy materials can be machined

- Custom complex monel cnc machined parts at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Monel K500 Machined Parts & Case Studies

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make Monel K500 prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making Monel K500 concept models and precise functional components. Understanding the properties of different supper alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on monel alloy. Be-cu prototyping company provides a range of solutions for the machining of Monel K500 parts.

The Industries & Applications Of Machining Monel K500

Monel K500 is a nickel-copper alloy known for its excellent combination of high strength, toughness, and resistance to corrosion and erosion. These properties make it highly suitable for a wide range of industries and applications. Below is an in-depth exploration of the various industries where Monel K500 is utilized and the specific applications within these industries.

CNC Machining Monel K500 For Marine Industry

- Propeller Shafts and Pump Shafts:Monel K500 is extensively used for propeller shafts and pump shafts in marine environments due to its excellent resistance to seawater corrosion and high mechanical strength.

- Seawater Valves and Fittings:The alloy’s ability to withstand the corrosive effects of seawater makes it ideal for valves, fittings, and other components that come into direct contact with seawater.

- Marine Fasteners and Hardware:Monel K500 is used to manufacture bolts, screws, nuts, and other hardware that need to maintain integrity in harsh marine environments.

- Fish Netting and Trawling Equipment:The corrosion resistance and durability of Monel K500 make it suitable for fishing netting, trawling equipment, and other maritime gear that is frequently exposed to seawater.

CNC Machining Monel K500 For Aerospace Industry

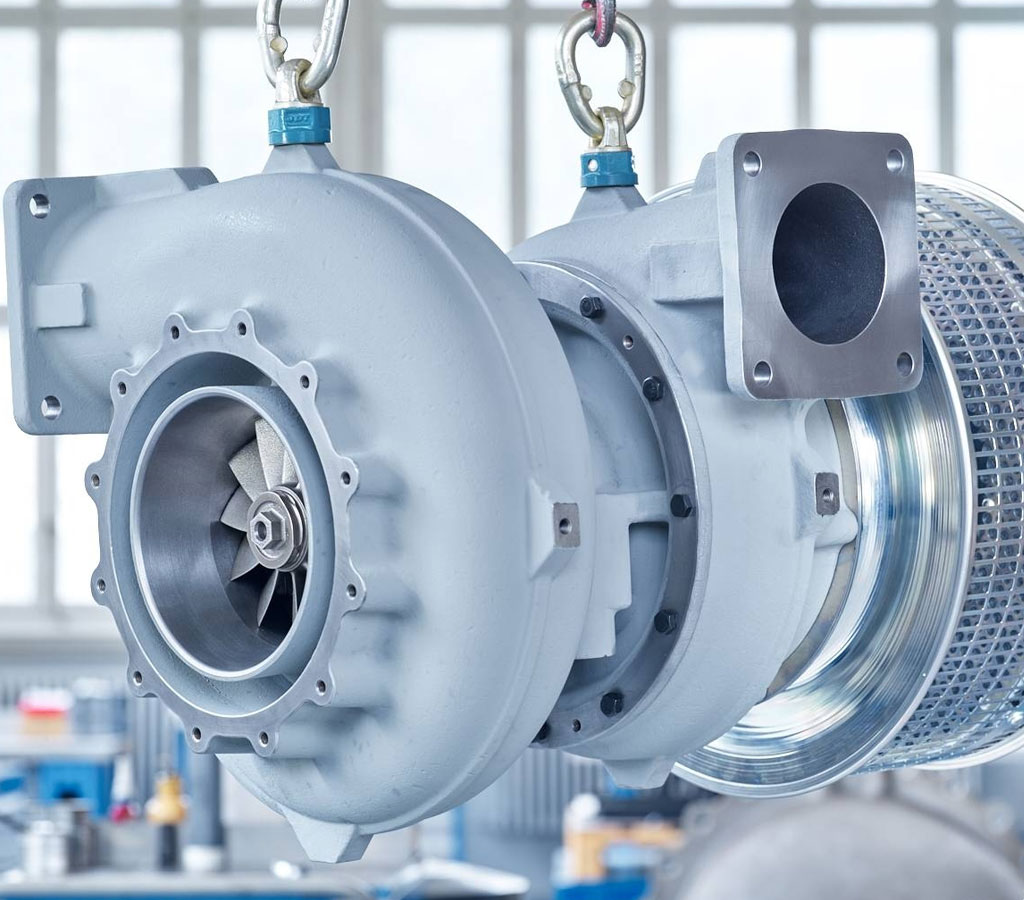

- Turbine Blades and Engine Components:The high strength and corrosion resistance of Monel K500 make it suitable for use in turbine blades and other engine components that must endure high temperatures and corrosive environments.

- Landing Gear Components:Monel K500 is used in the landing gear of aircraft due to its strength, toughness, and ability to withstand impact and stress.

CNC Machining Monel K500 For Oil and Gas Industry

- Downhole Tools and Equipment:Monel K500 is used in the construction of downhole tools such as drill collars, tool joints, and valve components that are exposed to extreme conditions deep within the earth.

- Oil Well Drilling Components:The alloy’s strength and corrosion resistance are essential for components involved in oil well drilling, such as drill bits and drill pipe joints.

- Valves, Pumps, and Fittings:Monel K500 is used in various valves, pumps, and fittings that handle corrosive fluids in oil and gas extraction and processing.

CNC Machining Monel K500 For Medical Industry

- Medical Instruments and Devices:The biocompatibility, corrosion resistance, and mechanical strength of Monel K500 make it suitable for various medical instruments and devices.

- Orthopedic Implants:Monel K500 is used in orthopedic implants and surgical tools due to its strength, durability, and resistance to body fluids.

CNC Machining Monel K500 For Renewable Energy Industry

- Wind Turbine Components:Monel K500 is used in various components of wind turbines, such as shafts, bearings, and fasteners, due to its high strength and resistance to environmental corrosion.

- Hydropower Equipment:The alloy’s resistance to corrosion and erosion makes it suitable for components used in hydropower plants, such as turbine blades and pumps.

Online Cooperate With Monel K500 Machining Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision cnc machining and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.