Polyetheretherketone (PEEK) is a high polymer composed of repeating units containing one ketone bond and two ether bonds in the main chain structure, and is a special polymer material. It has physical and chemical properties such as high temperature resistance and chemical resistance. It is a kind of semi-crystalline polymer material. It can be used as high temperature resistant structural material and electrical insulating material. It can be compounded with glass fiber or carbon fiber to prepare reinforcing material. Generally, a type of polyarylene ether polymer obtained by condensation with aromatic dihydric phenol is used.

PEEK plastic material has numerous applications in aerospace, medical devices (as artificial bone to repair bone defects) and in industry.

Cnc Machining PEEK Parts – PEEK Machined Services In China

Looking for reliable, quick-turn PEEK cnc machining services suppliers and CNC Machined product manufacturers?Using PEEK materials (chemically known as polyetheretherketone) is ideal for a wide spectrum of CNC machining applications where thermal, chemical, and combustion properties are critical to performance.BE-CU.COM is experienced expert for precision cnc machining peek parts.Our Precision PEEK CNC machining services include milling, boring, drilling, tapping, EDM, routing, rolling, routing, laser cutting, waterjet cutting, facing, threading, reaming, taper turning, tapping, knurling, gear hobbing, broaching, cutting, counterboring, countersinking. Secondary operations include assembly, centerless grinding, heat treating, polishing, electroplating, powder coating and welding.

PEEK™ (Polyether Ether Ketone) is a high-performance thermoplastic polymer known for its excellent mechanical, thermal, and chemical properties. PEEK™ grades vary based on their specific formulations, which are tailored to meet different application requirements. Here are some common grades of PEEK™:

Unfilled PEEK™

Glass-Filled PEEK™

Carbon-Filled PEEK™

Bearing Grade PEEK™

Medical Grade PEEK™

Electrically Conductive PEEK™

Capable of handling peek parts from 0.08 to 80 inches (2-500mm) length by 0.08 to 30 inches (2-500mm) wide and 0.08 to 20 inches (2-2000mm) inches diameter. Peek Parts turning from 0.1 to 36 inches in length and 0.1 to 24 inches diameter. Tolerance ranges up to +/-0.0005 inches.

Serving many different industries with offshore contract manufacturing, automation, medical device,OEM/ODM, engineering, product development, prototyping, pilot production, quality assurance and supply chain management services. We treat all our customers equally and there are no simple and complex projects. Whether small or big, every project is the same. Our commitment to meet customer satisfaction beyond their expectations has helped us grow as one of the leading PEEK CNC machining services providers in the china.

Do you have specific PEEK machining requirements? Feel free to get in touch with our PEEK machining experts to discuss the use of PEEK plastic to machine your parts for industrial applications. Our experts will respond to you at the earliest.

CNC Milling PEEK

PEEK CNC milling is a subtractive process that using 3-, 4-, & 5-axis milling machines with various of cutting tools to apply a machined surface finish on PEEK plastic material for creating complex 3D shapes. With our 70 machining centers, we can handle large volume runs, without compromising speed and quality. Please check cnc milling services with any questions.Our team of engineers and machinists program the equipment to optimize cutting time, surface finish, and final tolerance to meet your design specifications

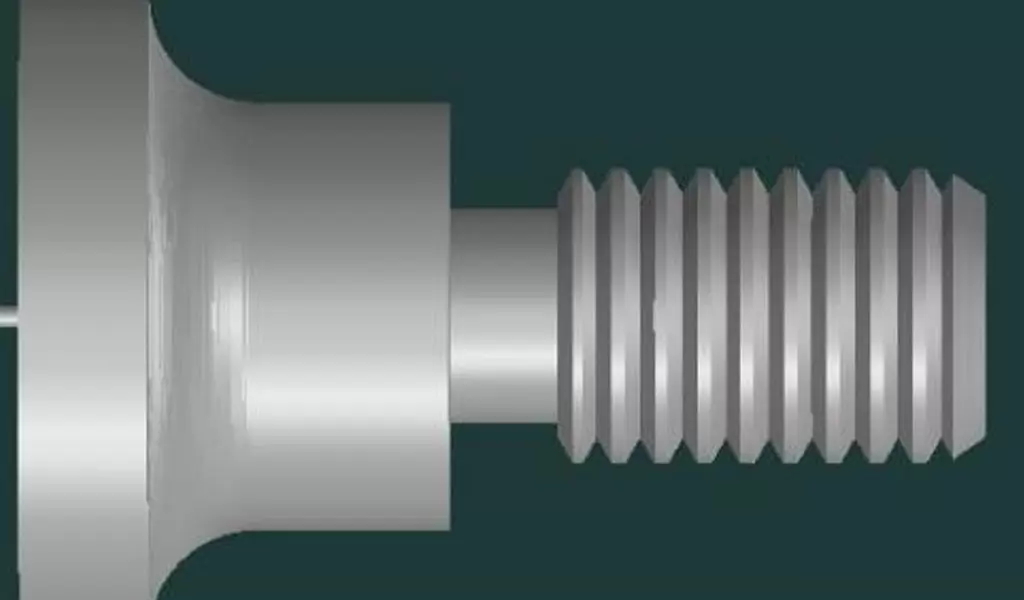

CNC Turning PEEK

PEEK CNC turning is a more efficient method to manufacture round shaped components from PEEK bars or tubes, such as shafts, worms. Our CNC lathes enable high speed and high-quality turning of both PEEK plastics,available for one-off prototypes.Known throughout the industry for the unsurpassed quality and accuracy of our precision PEEK CNC turning, we can ensure the performance of each PEEK component we produce. We have many years’ experience in CNC turning PEEK, and our reputation for quality continues to grow.

How To Ensure PEEK Plastic Machining Accuracy?

Through a scientific/rigorous method and a non-impetuous mind

- The team members have 35 years of experience in plastic machining more than 100,000 precision products.

- Constant temperature cnc machining environment ●5-axis ultra-precision machining equipment, achieving 0.1μ resolution, 1μ cutting ●Equipped with ultra-high-precision Renishaw probe (on-line detection and compensation of parts during cnc plastic machining, so that the results can be seen before leaving the machine)

- Cooperate with global engineering plastics material suppliers to ensure the quality of raw materials

- ISO standardized management and evolving precision machining technology for special engineering plastics

- What can really achieve ultra-high precision for complex engineering plastic products is:

- Persistence in mission, love for the industry and not impetuous heart

Why Choose Our PEEK Cnc Machining Service?

- Save time and money for your PEEK project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of PEEK grades and plastic materials can be machined

- Custom complex PEEK machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

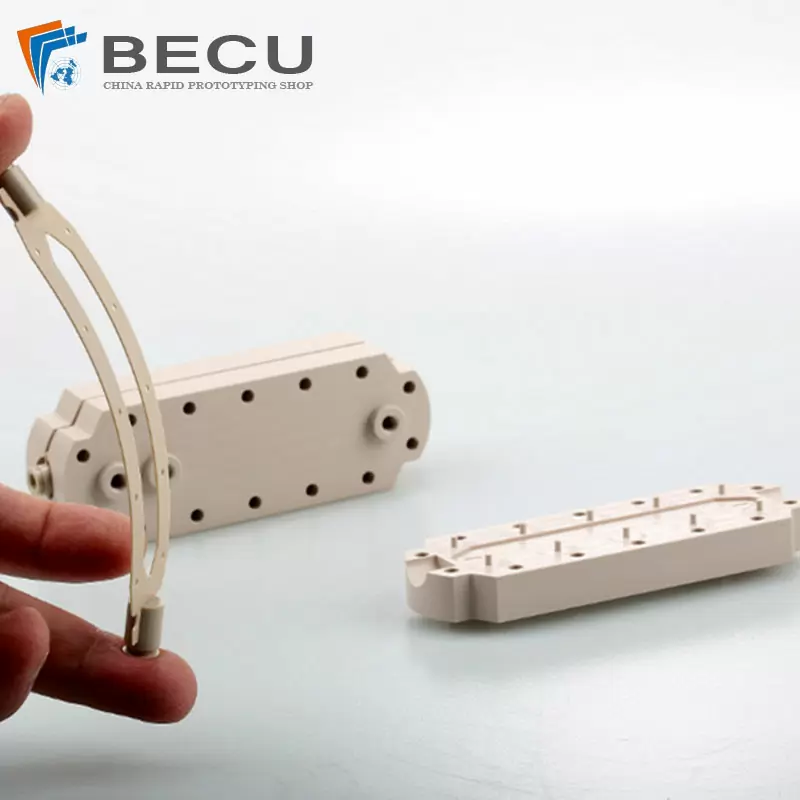

Top PEEK Cnc Machining Case Studies

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make PEEK prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making PEEK concept models and precise functional components. Understanding the properties of different peek plastic, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on PEEK. Be-cu prototyping company provides a range of solutions for the machining of PEEK plastic parts.

-

Precision Engraving Special-Shaped Natural Color PEEK Parts

-

5 Axis Machining Black PEEK Plastics Chip Mount Base

-

5 Axis CNC Precision Machining PEEK Valve Body And Impeller

-

Microhole Machining PEEK Module Probe Block

-

5 Axis Machining PEEK Plastics Mechanical Hub

-

Precision CNC Turning Machining PEEK Plastic Fasteners

-

ISO 9001:2015 Certified Machining PEEK Balance Impeller

-

5 Axis Machining Special Engineering PEEK Plastic Parts

-

Precision 5 Axis CNC Machining Special PEEK Screw

-

CNC Machining 30% PEEK Exhaust Guide Pipe

-

5-Axis CNC Machining Black PEEK Flanges

-

Custom Black PEEK Pet Hair Dryer Fan

What Is PEEK Plastic & The Features Of PEEK

PEEK (polyetheretherketone) plastic raw material is an aromatic crystalline thermoplastic polymer material with high mechanical strength, high temperature resistance, impact resistance, flame retardant, acid and alkali resistance, hydrolysis resistance, wear resistance, fatigue resistance, radiation resistance and good electrical properties.

- High temperature resistance: It has high glass transition temperature (Tg=143°C) and melting point (Tm=343°C), its thermal deformation temperature under load is as high as 316°C, and its instantaneous use temperature can reach 300°C.

- Mechanical properties: It has rigidity and flexibility, especially the fatigue resistance under alternating stress is very outstanding, which is comparable to alloy materials.

- Self-lubrication: It has excellent sliding properties and is suitable for occasions where low friction coefficient and wear resistance are strictly required, especially PEEK modified with carbon fiber and graphite in a certain proportion has better self-lubricating properties.

- Corrosion resistance: Except for concentrated sulfuric acid, PEEK is insoluble in any solvent and strong acid and alkali, and it is resistant to hydrolysis and has high chemical stability.

- Flame retardancy: It is self-extinguishing, even without any flame retardant, it can reach the 94V-0 level of the UL standard.

- Ease of machining: It has the characteristics of good high temperature fluidity and high thermal decomposition temperature. Various machining methods can be used: injection molding, extrusion molding, compression molding and melt spinning.

- Peeling resistance: The peeling resistance is very good, so it can be made into a thinly coated wire or magnet wire, and can be used in harsh conditions.

- Fatigue Resistance: The best fatigue resistance among all resins.

- Radiation resistance: The ability to withstand high radiation is very strong, surpassing that of polystyrene, which has the best radiation resistance among general-purpose resins. It can be made into a high-performance product that can maintain a good insulating ability when the γ-irradiation dose reaches 1100Mrad.

- Hydrolysis resistance: PEEK and its composite materials are not chemically affected by water and high-pressure water vapor, and products made of this material can maintain excellent properties when used continuously in high-temperature and high-pressure water.

- Smoke: PEEK has the lowest smoke among plastics.

- Toxic gas escape: PEEK is the same as many organic materials. When decomposed at high temperature, PEEK mainly produces carbon dioxide and carbon monoxide. Using the British aircraft test standard BSS 7239, a very low concentration of toxic gas can be detected. This detection process needs to be in 1. Completely burn 100 grams of sample in a cubic meter of space, and then analyze the poisonous gas produced in it. The toxicity index is defined as the ratio of the concentration of poisonous gas produced under normal conditions to the lethal dose in 30 minutes. The index of PEEK450G is 0.22. And no acid gas was detected.

- Insulation stability: has good electrical insulation properties and maintains it to a very high temperature range. Its dielectric loss is also small at high frequencies.

- Stability: Has excellent dimensional stability properties, which is important for some applications.

Changes in environmental conditions such as temperature and humidity have little effect on the size of PEEK parts, which can meet the requirements for use under high dimensional accuracy requirements.

- The injection molding shrinkage of PEEK plastic raw materials is small, which is very beneficial to control the dimensional tolerance range of PEEK injection parts, so that the dimensional accuracy of PEEK parts is much higher than that of general-purpose plastics;

- The thermal expansion coefficient is small, and with the change of temperature (caused by the change of ambient temperature or frictional heat generation during operation), the size of PEEK parts changes very little;

- Good dimensional stability. The dimensional stability of plastics refers to the dimensional stability of engineering plastic products during use or storage. This dimensional change is mainly due to the increase in the activation energy of polymer molecules. caused by some degree of curling;

- PEEK has outstanding heat-resistant hydrolysis properties, low water absorption under high temperature and high humidity environment, and there is no obvious change in size of general-purpose plastics such as nylon due to water absorption.