Cnc Machining 430 FR Stainless Steel

430 FR is a ferritic stainless steel that contains chromium and nickel. The “FR” in its name stands for “free machining,” indicating that it is designed to be easily machined using standard machining techniques. This type of stainless steel is known for its corrosion resistance, good formability, and machinability.

When CNC machining 430 FR stainless steel, the material can be easily shaped and cut into specific forms with precision. This makes it suitable for applications where both corrosion resistance and machining ease are important factors.

In summary, CNC machining is a versatile and precise manufacturing process, and 430 FR stainless steel is a type of stainless steel known for its free machining properties, making it well-suited for CNC machining applications.

The Composition Of 430 FR Stainless Steel

- Type: Stainless Steel

- Alloy: 430 FR

- Tolerances for 1/2″ Dia.: +.002

- Material Cost Factor: 3

- Machining Cost Factor: 2.7

- General Characteristics:Corrosion resistance and high electrical resistivity

430 FR stainless steel is a ferritic stainless steel alloy, and its composition is characterized by a combination of elements that contribute to its properties. The typical composition of 430 FR stainless steel includes:

- Chromium (Cr): Chromium is the primary alloying element in stainless steel, and it imparts corrosion resistance to the material. In the case of 430 FR, chromium content is typically around 17-18%.

- Nickel (Ni): Nickel is added to improve corrosion resistance and enhance the material’s formability. However, the nickel content in 430 FR stainless steel is relatively low compared to austenitic stainless steels. The nickel content is typically around 0.60-1.10%.

- Manganese (Mn): Manganese is added to improve the steel’s strength and workability. The manganese content in 430 FR is generally in the range of 1.0-1.5%.

- Silicon (Si): Silicon is added to improve the steel’s resistance to scaling at elevated temperatures and enhance its mechanical properties. The silicon content in 430 FR stainless steel is typically around 1.0%.

- Carbon (C): Carbon content in 430 FR stainless steel is kept relatively low to maintain good weldability and corrosion resistance. The carbon content is typically around 0.12% or lower.

- Phosphorus (P) and Sulfur (S): These elements are controlled to low levels to ensure good machinability. The presence of sulfur is often intentionally increased to enhance the free machining characteristics of the steel.

- Other Elements: Trace amounts of other elements, such as nitrogen and copper, may be present in 430 FR stainless steel, depending on the specific production specifications.

The Benefits Of 430 FR Stainless Steel Cnc Machining

CNC machining of 430 FR stainless steel offers several benefits, making it a suitable choice for certain applications. Here are some of the advantages associated with CNC machining of 430 FR stainless steel:

Free Machining Properties

Corrosion Resistance

Formability

Cost-Effective Machining

Suitable for High-Volume Production

Applications in Automotive and Industrial Sectors

Wide Range of Machining Operations

It’s important to note that while 430 FR stainless steel offers advantages in machining, the choice of material should also consider specific application requirements such as mechanical properties, heat resistance, and overall performance. Additionally, the CNC machining process should be carried out with appropriate tooling and techniques to fully leverage the benefits of 430 FR stainless steel.

Stainless Steel Alloy 430 FR CNC Machining Service

430 fr stainless steels have 11 percent chromium, and 1 percent manganese composition. With heat treated to harden,430 fr stainless steels have high carbon content, which contributes to its martensitic crystalline form. This structure provides high wear resistance and structural integrity after CNC machining. These steels aren’t’ excellent corrosion or rust inhibitors.

We, at Be-Cu Prototype company, are committed to providing high-quality sus machining services at competitive prices. This commitment has brought us recognition as one of the leading 430 fr CNC machining services in the china. Our broad experience combined with our expertise has helped us take up various complex projects with ease. Our long list of happy and satisfied customers is the testament of our commitment to provide quality services at fastest turnaround times. Contact us or request a quote today about utilizing our 430 fr stainless steel CNC machining services.

Industries & Applications

430 FR stainless steel, known for its free machining properties and corrosion resistance, finds applications in various industries where these characteristics are beneficial. CNC machining of 430 FR stainless steel is particularly suitable for the following industries and applications:

- Solenoid valves

- Injectors

- Fasteners and Bolts

- Shafts and Bushings

- Food Processing Equipment

- Connectors and Housings

- Medical Parts

- Architectural Components

- Marine Hardware

CNC SUS 430 fr Capabilities

- Swiss machining 430 fr Stainless Steel

- CNC milling 430 fr Stainless Steel

- CNC turning 430 fr Stainless Steel

- 5 Axis machining 430 fr Stainless Steel

- CNC cutting 430 fr Stainless Steel

- Turn-mill machining 430 fr Stainless Steel

- EDM Cutting 430 fr Stainless Steel

- More

You can contact us by requesting a quote for any 430 fr Stainless Steel manufacturing process. One of our project managers will review your application and get a quote and DFM feedback for you within 12 business hours.

Why Choose Our 430 fr Stainless Steel Cnc Machining Service?

- Save time and money for your 430 fr Stainless Steel project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of stainless steel grades and alloy materials can be machined

- Custom complex stainless steel cnc machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Stainless Steel Alloy 430 FR Machined Parts

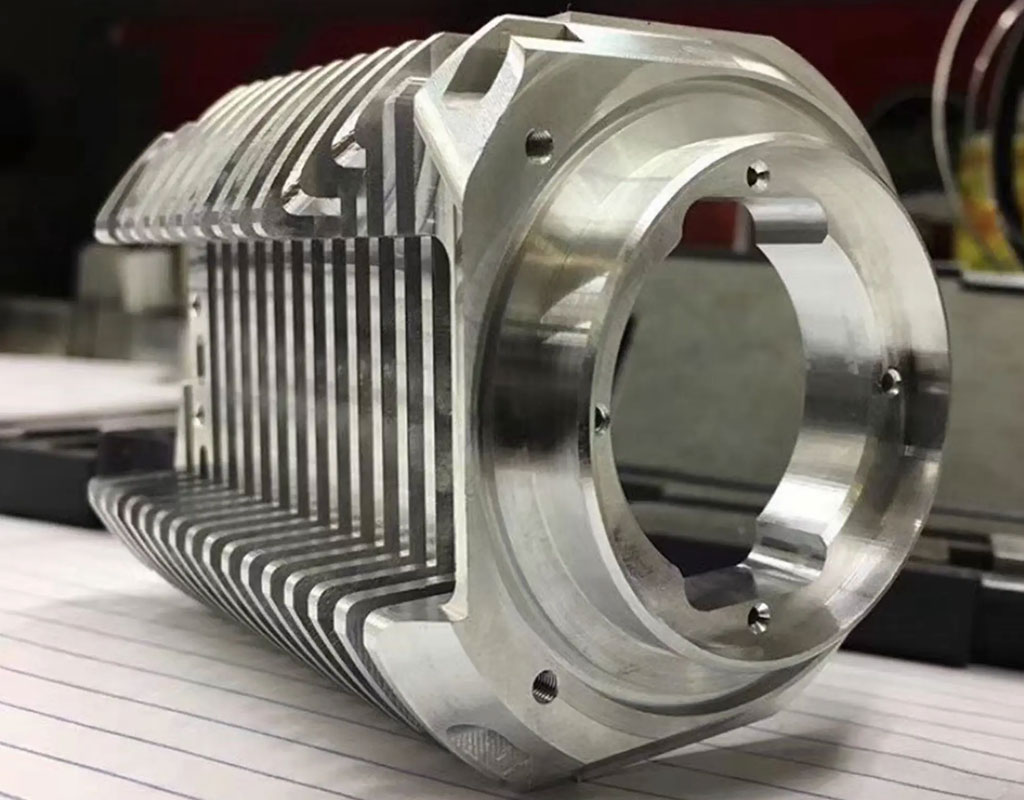

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make 430 fr Stainless Steel prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes laser cutting is the only option. Our company has rich experience making 430 fr Stainless Steel concept models and precise functional components. Understanding the properties of different copper alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on stainless steel alloy. Be-cu prototyping company provides a range of solutions for the machining of Stainless Steel parts.

-

Swiss Turning 304 Stainless Steel Medical Threaded Rod

-

Swiss Machining Stainless Steel Pin Cylindrical Discharge Needle

-

Swiss Machining Stainless Steel Alloy Medical Disposable Trocar

-

Screw CNC Machining Non-Standard Mandrel Tube Shaft

-

Precision Swiss Machining Tooth Drive Screw Rod

-

Precision CNC Turning Stainless Steel Transmission Arm Parts

-

Precision Cnc Turning Stainless Steel 316 Machine Screw

-

Precision 316 Stainless Steel Cookware Boiler Cover For Kitchen

-

Custom Stainless Steel Marine Deck Screws

-

Custom Stainless Steel 316 Goblet By Turning

-

CNC Turning Stainless Steel 316 Men Spinner Rings

-

CNC Turning Stainless Steel 316 Grinding Core For Coffee Mill

Mechanical Properties Of Stainless Steel Alloy 430 fr

The mechanical properties of stainless steel alloy 430 FR (Free Machining) are influenced by its composition and structure. Here are the typical mechanical properties of 430 FR stainless steel:

- Tensile Strength:Tensile strength is the maximum stress that a material can withstand while being stretched or pulled.The tensile strength of 430 FR stainless steel is typically in the range of 450 to 600 megapascals (MPa).

- Yield Strength:Yield strength is the amount of stress at which a material begins to deform plastically.The yield strength of 430 FR stainless steel is generally around 240 to 310 MPa.

- Elongation:Elongation represents the percentage increase in the original length of a material that occurs before rupture during tensile testing.The elongation of 430 FR stainless steel is typically around 25% or more.

- Hardness:Hardness measures the resistance of a material to deformation, particularly through indentation.The hardness of 430 FR stainless steel is commonly in the range of 160 to 190 Brinell hardness (HB).

- Modulus of Elasticity:The modulus of elasticity, also known as Young’s modulus, indicates the stiffness of a material.The modulus of elasticity for 430 FR stainless steel is typically around 200,000 megapascals (MPa).

- Machinability:Machinability is a key property for free machining stainless steels like 430 FR.430 FR stainless steel is specifically designed for improved machinability, allowing for high-speed cutting and efficient machining processes.

These mechanical properties make 430 FR stainless steel suitable for applications that require a combination of corrosion resistance, machinability, and formability. The alloy’s performance in machining operations, along with its resistance to corrosion, makes it a favorable choice for industries such as automotive, industrial equipment, electronics, and more.

It’s important to note that the mechanical properties can vary based on factors such as the specific manufacturing process, heat treatment, and the presence of impurities. Therefore, it’s advisable to consult the material specifications provided by manufacturers for precise information on the mechanical properties of 430 FR stainless steel.

Online Cooperate With Stainless Steel Alloy 430 FR Machining Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision cnc machining and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.