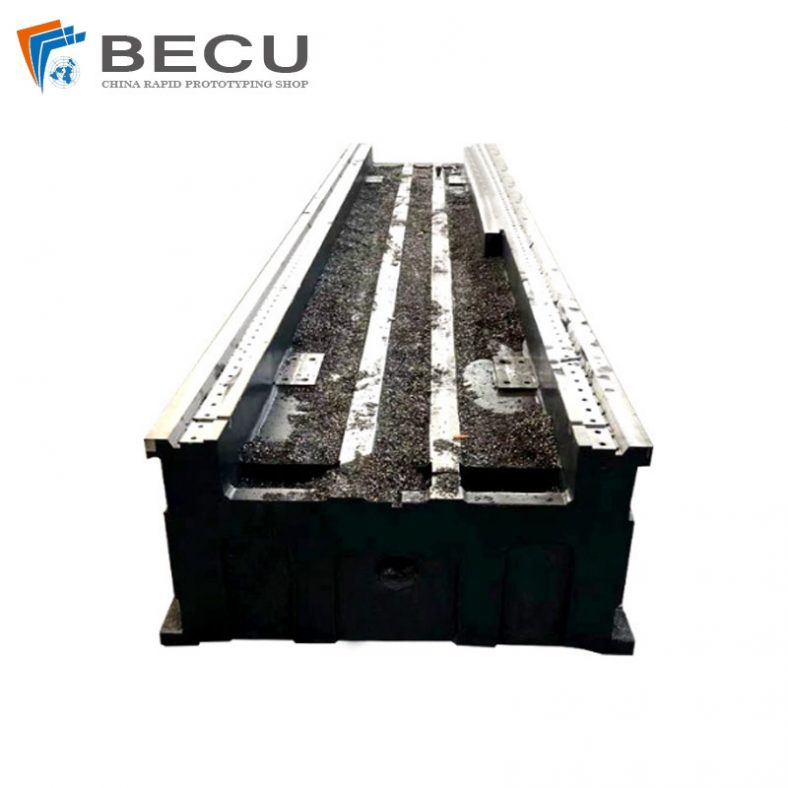

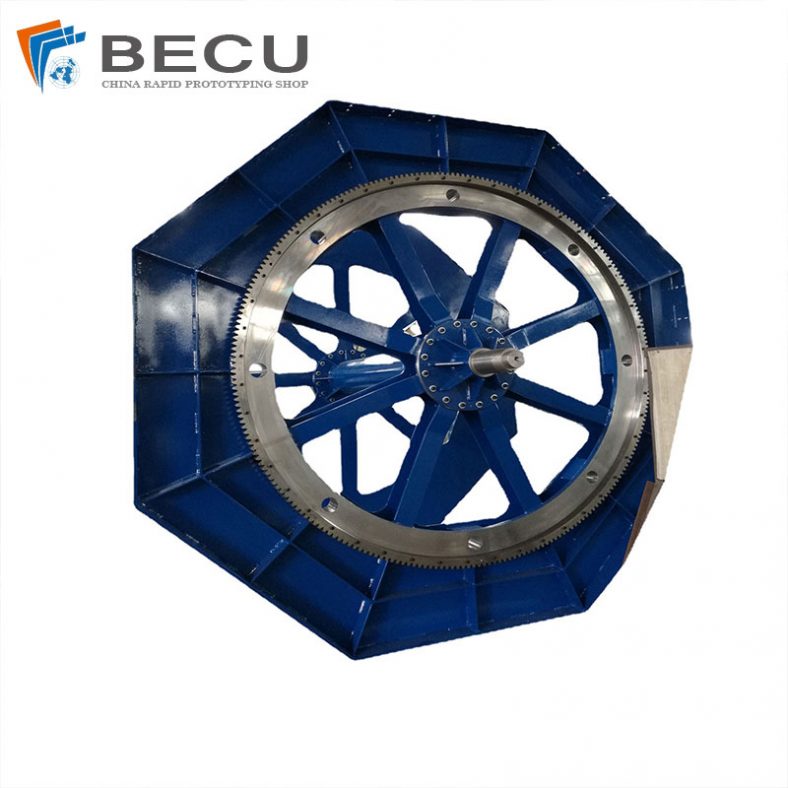

Big Size Lost Foam Casting Parts

- No.: Lost Foam Casting Parts

- Color: Custom

- Surface Treatment: Custom

- Product Material: Custom

- Proofing Cycle:7 days(100000 pcs/M)

- Application: Precision Cnc Machining

- machining Factory: Be-cu Rapid Prototyping Companies

- Product Category: Lost Foam Casting Parts

- Production Process: Large CNC Machining

- Size: According To Customer’s Drawings

High-Quality Big Size CNC Machining Lost Foam Casting Parts

Lost foam casting is relatively a new casting technique that has the characteristics of both investment casting and sand casting. It is similar to evaporative pattern casting, with the pattern made up of foam instead of wax. The foam pattern is coated with refractory material, as in investment casting; Our shops are accustomed to machining large lost foam castings, which is not the norm for CNC shops. We know how to apply CNC to casting purposes specifically. Be-cu.com’ area of expertise includes production CNC machining. We work with this technology in various applications, which has given us experience that other foundries and CNC machine shops can’t match.

You can trust Be-cu.com with your project, contact us today to get your free quote.

The Advantages Of Big Size CNC Machining Lost Foam Casting Parts

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Big Size CNC Machining Lost Foam Casting Parts

| Material | Aluminum |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Milling, Drilling, 5 Axis Cnc Machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Lost Foam Casting Parts |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Prototype Company

At Be-cu.com, we provide large and heavy machining services for a vast range of industries. These industries may include niche sectors that require high accuracy, specialist, quality parts, and large part without sacrificing quality. Based on our experience and decades of professionalism, we can carry out large CNC machining projects in-house. This is done by taking them through the initial consultation to the cnc machining large parts as well as inspection of the final products.

If you are looking for a supplier of big size CNC machined parts, no match it is prototyping or volume order, we can make for you. Talk to us by today.