Cnc Machining For Tantalum

Tantalum is a rare, hard, blue-gray metal known for its corrosion resistance and excellent conductivity. Discovered in 1802 by Swedish chemist Anders Gustaf Ekeberg, tantalum has become invaluable in various industries due to its unique properties. Its primary source is the mineral columbite-tantalite, also known as coltan, which is mined primarily in Africa.

In the periodic table, tantalum is designated by the symbol Ta and atomic number 73. It is part of the refractory metals group, which are known for their resistance to heat and wear. Tantalum’s melting point of 3017°C (5463°F) is among the highest of all elements, making it suitable for high-temperature applications.

Tantalum’s combination of physical, chemical, and mechanical properties makes it indispensable in several high-tech applications. In the electronics industry, tantalum capacitors are crucial due to their ability to store and release energy efficiently. The aerospace sector utilizes tantalum for its strength and resistance to extreme environments, while the medical field employs it in surgical implants and instruments due to its biocompatibility.

Moreover, tantalum’s corrosion resistance makes it ideal for use in the chemical processing industry, where it can withstand highly reactive environments. The metal is also vital in the nuclear industry, given its ability to endure radiation and extreme temperatures.CNC machining operates via numerical control, wherein a software program is designated to control an tantalum metal block. The software dictates the series of commands necessary to create a desired end product. This automated control enhances precision, repeatability, and efficiency, making tantalum CNC machining integral to modern manufacturing.

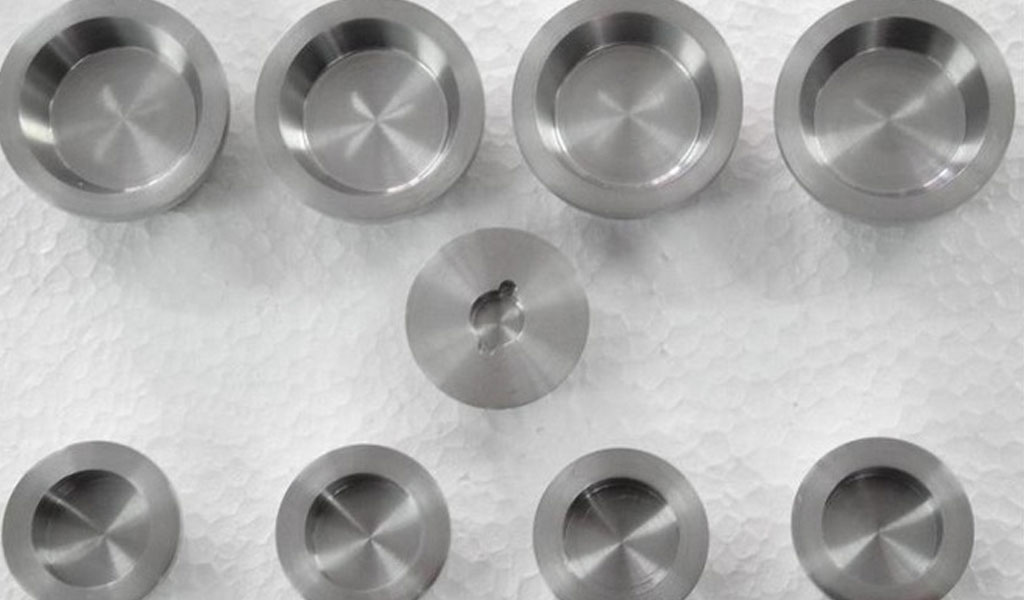

Tantalum Machining Suppliers – CNC Machining Tantalum Alloy Parts

Need precision machined tantalum components? In the past three years, we have provided customized services of tantalum alloy parts to dozens of equipment companies in the medical,oil and gas industry.

Multiple CNC machines including CNC machining center,gantry milling machines, CNC lathes, drills, and advanced measuring equipment ensure our in-house capacity to deliver your Tantalum CNC machining parts with the most competitive prices, short lead time and on-time shipping.

At BE-CU.COM, both rapid prototyping and low/medium/high-volume production are available based on customers’ requirements. Our online tantalum alloys CNC machining services also support one stop service from product design to finishing services, to help clients who just have a rough concept about the end-use tantalum products.Fast send your 2d-3d drawing to our email for requesting a free quote, we’ll analyze your file and give you a prompt reply.

Tantalum Milling

We understands the demands for high-performance aerospace parts and medical machined components.

Through our past precision machined component projects, we have developed internal processes that identify critical dimensions for all projects and have the capabilities to mill tantalum alloys successfully. Our expertise provides an unmatched value for our customers.

As a dependable milling option for many components, 3-axis milling is well-suited for milling simple, large, or high-volume parts. Designed for automatic operation, BE-CU can build fixtures that hold multiple parts to cut, all in one setup. Our 3-axis lager milling machine works well for high-volume material removal, providing increased accuracy and efficient machining of a wide range of parts.

Advantages Of Tantalum Machining

- Great precision and high tolerance ensure high-quality tantalum parts

- Time and cost-saving, great speed of Machining tantalum part

- Allows products ordered to be made precisely to the specifications stated

- Complex tantalum parts for high tech industry can be machined

Why Choose Our Tantalum Cnc Machining Service?

- Save time and money for your tantalum project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of tantalum grades and alloy materials can be machined

- Custom complex tantalum machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Tantalum Prototype And Other Metal CNC Machining Case Studies

Whether you require machined tantalum prototypes or custom tantalum parts for your automotive, aerospace applications or medical device component, we can easily help you. With our expertise in CNC tantalum machining and the ability to integrate external combined processes, we can ensure the best performance for your machining tantalum projects.Understanding the properties of different tantalum alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on tantalum alloy. Be-cu prototyping company provides a range of solutions for the machining of tantalum parts.

-

3D Printed Inconel Exhaust Manifold

-

Crawler Robot Components for Oil Pipeline Interior Walls

-

Restoration of Petroleum Splined Shafts through Supersonic Thermal Spray Coating

-

Vertical CNC Milling SUS316L Medical Reagent Bracket

-

CNC Machining Monel K500 Butterfly Valve

-

CNC Machining Bakelite Circuit Board Test Fixture

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

5 Axis CNC Machining Spiral Bevel Gear Mold