What is Titanium & What is it Used for – Aviation Application

As a high-strength alloy material, titanium alloy has been widely used in aerospace and other high-end equipment fields because of its excellent high specific strength, good corrosion resistance, super fracture toughness and fatigue resistance, and is known as 21 The most valuable strategic metal material in the century.

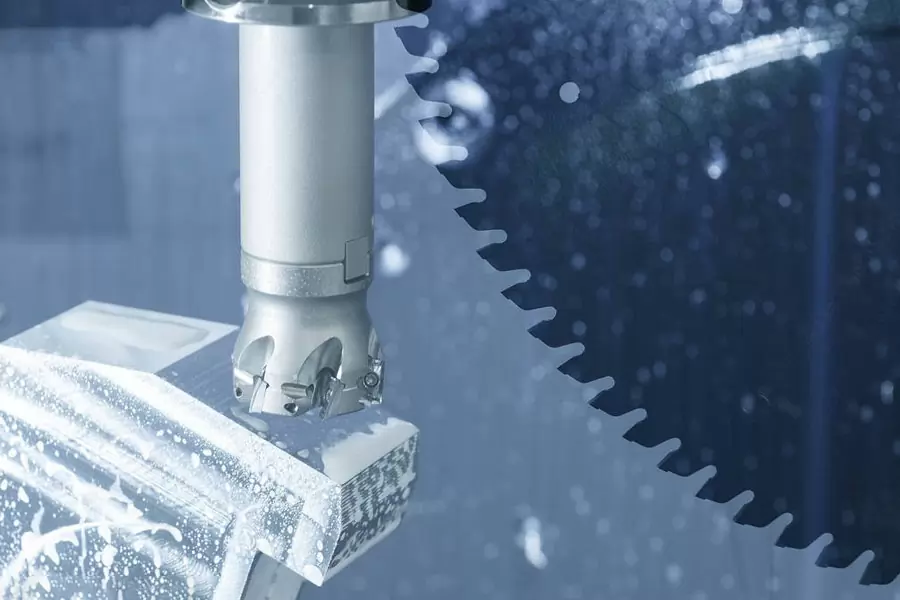

The amount of titanium alloy is often used as an indicator to measure the advanced degree of aircraft material selection and the development level of the aviation industry, which is closely related to the combat capability of the aircraft. The purpose of mechanical manufacturing is to manufacture components that meet shape accuracy and service performance. However, due to the high strength, low thermal conductivity, easy sticking to the tool and strong affinity with the tool, the titanium alloy material can easily cause poor surface machining quality during the titanium machining process. For example, the cutting heat generated in the titanium machining process is not easy to be transmitted, and is often concentrated in some small areas, resulting in excessively high local cutting temperature, resulting in surface burns, which in turn affects its surface integrity.

As a key material for high-end equipment parts such as aero-engines, titanium alloys have good high specific strength, excellent corrosion resistance, and super fracture toughness and fatigue properties.As a typical aviation difficult-to-machine material, the surface integrity of titanium alloys during the china cnc machining process has a crucial impact on its service performance and reliability.

Titanium Machining Service – Custom Titanium Cnc Machining Parts China

Looking for reliable, quick-turn titanium machining services suppliers and CNC Machined product manufacturers?

Be-cu prototype company is a CNC machining titanium China suppliers specialized in custom titanium alloy parts manufacturing for more than 30 years, with advanced in-house equipment and tool facility, proficient machinists, and rich expertise, we can provide precision titanium machining services and customize quality titanium CNC machining parts with exact specification, budget prices and on-time delivery based on your requirements. In our titanium CNC machining shop, milling, turning, drilling and more processes are available, as well as excellent surface finishing. Our lineup of titanium and titanium alloy components can be used in broad range of industries and applications, typically including airplane parts and fasteners, telecom parts, compressor blades, medical parts, automotive and motorcycle parts. We are aiming to establish close and friendly cooperation with worldwide customers.

The Titanium Alloy Material Of Cnc Machining

Titanium machined parts are known for their high strength and weight; it is also ductile, corrosion resistant against salt and water, and has a high melting point, making it the perfect option for many industries and applications.So we can offer you the best titanium cnc machining solution according to your requirements of titanium parts and products.

Why Choose Our Titanium Cnc Machining Service?

- Save time and money for your titanium project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of titanium grades and alloy materials can be machined

- Custom complex titanium machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

The Properties Of Titanium Alloy

Titanium alloys have high specific strength (ratio of strength and density), and titanium alloys have played an irreplaceable role in aviation, military industry, shipbuilding, chemical industry,metallurgy, machinery, medical and other fields. Titanium and titanium alloys have many excellent properties, mainly reflected in the following aspects:

- High strength. Titanium alloy has high strength, its tensile strength is 686-1176MPa, and its density is only about 60% of steel, so its specific strength is very high.

- High hardness. The hardness HRC of titanium alloy (annealed) is 32-38.

- Low modulus of elasticity. The elastic modulus of titanium alloy (annealed state) is 1.078×10-1.176×10MPa, which is about half of steel and stainless steel.

- Excellent high temperature and low temperature performance. At high temperature, titanium alloy can still maintain good mechanical properties, its heat resistance is much higher than that of aluminum alloy, and its working temperature range is wide. At present, the working temperature of new heat-resistant titanium alloy can reach 550-600 °C; , the strength of the titanium alloy is higher than that at room temperature, and it has good toughness. The low-temperature titanium alloy can maintain good toughness at -253 ℃.

- Titanium has strong corrosion resistance. Titanium in the air below 550 ℃, the surface will quickly form a thin and dense titanium oxide film, so in the atmosphere, seawater, nitric acid and sulfuric acid and other oxidizing media and strong alkali, its corrosion resistance is better than most stainless steel.

Top Titanium Cnc Machining Case Studies

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make titanium prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making titanium concept models and precise functional components. Understanding the properties of different titanium alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on titanium alloy. Be-cu prototyping company provides a range of solutions for the machining of titanium parts.

-

5 Axis CNC Machining Medical Olecranon Plate

-

4 Axis CNC Machining Titanium Grade 5 Mobile Phone Buttons

-

Precision Swiss Turning Titanium Alloy Medical Shaft

-

Deep Hole CNC Turning Titanium Alloy Dispensing Needle

-

Precision Turning TC4 Alloy Medical Ultrasound Bead Needle

-

5 Axis Machining Optical Communication Parts And Telecom Parts

-

Titanium Alloy Internal Fixation Plate For Medical Equipment

-

Medical Sensor Power Supply Housing

-

5 Axis Cnc Machining Titanium Motorcycle Frame