Die casting is a versatile manufacturing process that has revolutionized the production of complex metal parts with high accuracy and efficiency. In recent years, die casting has been increasingly employed for the production of thin wall parts, where precision and lightweight design are critical.

What Is Thin Wall Die Casting

Thin wall die casting is a specialized form of the traditional die casting process that focuses on producing metal parts with extremely thin and lightweight walls. In conventional die casting, thicker sections and walls are often preferred to ensure the structural integrity of the final product.

However, as industries seek to reduce weight and improve efficiency in their products, there has been a growing demand for parts with thinner walls that maintain their strength and functionality.

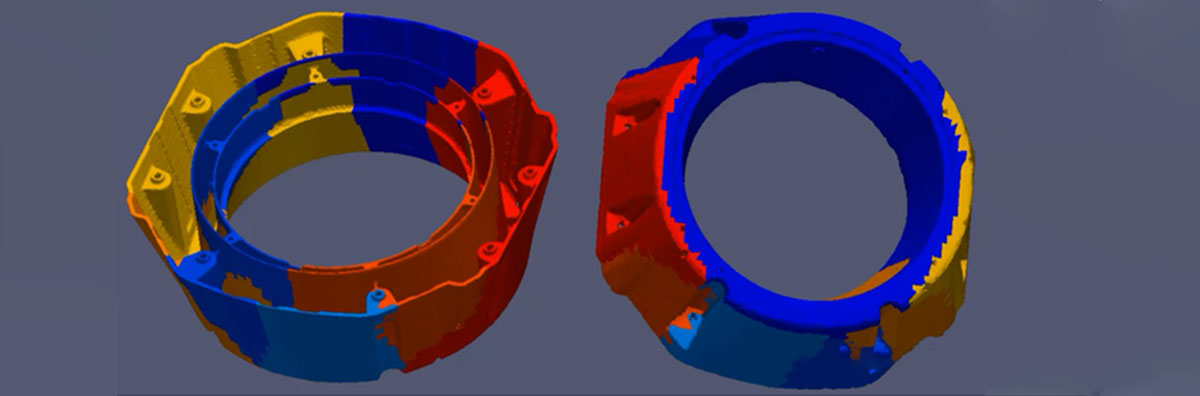

In thin wall die casting, the primary goal is to create parts with reduced wall thickness while still meeting the required mechanical properties and performance standards. This process involves unique challenges due to the increased likelihood of issues like rapid cooling, solidification, and potential defects. Successful thin wall die casting requires careful consideration of various factors, including material selection, mold design, gating and venting, process parameters, and advanced simulation techniques.

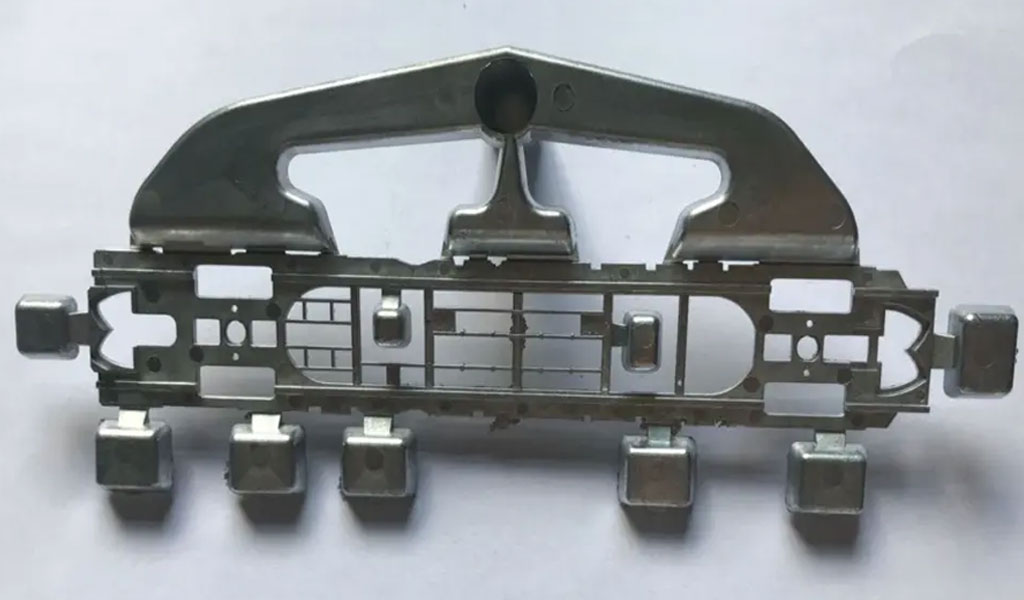

Thin wall die casting is commonly used in industries such as automotive, aerospace, electronics, and consumer goods, where lightweight design is crucial for improving fuel efficiency, enhancing maneuverability, or optimizing overall product performance. The process allows manufacturers to achieve intricate geometries and complex shapes while maintaining the benefits of die casting, such as high production rates, excellent surface finish, and dimensional accuracy.

In order to achieve successful thin wall die casting, manufacturers need to balance the challenges posed by thinner sections with innovative design approaches, advanced materials, and optimized process parameters. As technology continues to advance, the capabilities of thin wall die casting are expected to expand, enabling the production of even more intricate and lightweight parts for a wide range of applications.

Thin Wall Die Casting Services On Demand

Our Thin Wall Die Casting Services On Demand, designed to provide exceptional quality and efficiency for your complex and lightweight component production requirements.

In today’s dynamic market landscape, where precision and speed are paramount, our Thin Wall Die Casting Services have been meticulously developed to address the challenges faced by industries seeking lightweight, yet structurally robust components. Our cutting-edge technology, coupled with a dedicated team of experts, ensures that we can provide you with superior quality components that meet your exact specifications.Key features of our Thin Wall Die Casting Services On Demand:

- Advanced Technology: We have invested significantly in state-of-the-art die casting machinery that is optimized for producing thin wall components. Our equipment is capable of maintaining tight tolerances and delivering consistent results.

- Engineering Expertise: Our team of experienced engineers is committed to collaborating closely with your design team. This partnership enables us to refine your component designs for optimal manufacturability, ensuring seamless integration into your end products.

- Material Selection: We offer a range of materials suitable for thin wall die casting, each selected to meet specific performance and cost criteria. Our materials experts can guide you in choosing the best material for your application.

- Rapid Turnaround: We understand the importance of time-to-market. With streamlined processes and efficient workflows, we guarantee quick turnaround times without compromising on quality.

- Quality Assurance: Our quality control measures adhere to industry standards, ensuring that every component leaving our facility meets or exceeds the desired specifications. We take pride in delivering components that perform flawlessly in real-world applications.

- Customization: We understand that every project is unique. Our Thin Wall Die Casting Services are fully customizable to suit your project’s requirements, whether they involve size, shape, volume, or surface finish.

At Be-Cu, we are committed to fostering long-term partnerships based on trust, quality, and innovation. Our Thin Wall Die Casting Services On Demand have been tailored to empower your business to thrive in a competitive environment, offering unmatched quality and efficiency.

I invite you to connect with us to learn more about how our Thin Wall Die Casting Services can benefit your upcoming projects. Please feel free to reach out to me directly at [email protected] to schedule a consultation or to discuss any questions you may have.

Why Choose BE-CU Thin Wall Die Casting Service?

- Modern and advanced casting equipment to ensure highest accuracy of Thin Wall die casting parts.

- Vacuum die casting machine in house

- Aluminium High Pressure Die Casting machines from 450 ton to 3000 ton,max weight :60kg (133pound)

- 50 set cnc machine for machined castings parts,metal, extrusion etc.

- Powder coating production line,CMM,X-ray in house

- Has strong and professional technical team and efficient management operation system and is equipped with advanced manufacturing equipment, ensure you can get best Light parts of die casting service.

Certifications & Quality List

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for light parts customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Product Description Of Our Thin Wall Die Casting Services

Light Parts Die Casting Applications:

Thin Wall die casting parts can be applied to Drivetrain, Fuel, Brake, Suspension, Electronics or HVAC

Custom Colors:

Black, Natural, Blue, Green and different colors as your requirements

Surface Finishing:

Sand blasting, shot blasting, polishing, anodizing, oxidation, electrophoresis, chromate, powder coating and painting

Various Light Parts Die Casting Process:

Thin Wall Die Casting,Cold Chamber Die Casting, Hot Chamber Die Casting

Top Thin Wall Die Casting Case Studies

You have a complex part design, Be-cu Die Casting Company can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

CNC Machining Gas Stove Bottom Joint

-

Gravity Die Casting Custom Street Light Heat Sink

-

Die Casting LED Canopy Lights Heatsink For Gas Station

-

Zinc Die Casting PA10 Transformer Connector Terminal

-

Die Casting Aluminium Cookware Chassis

-

Die Casting Wheels With Aluminum Alloy 5 Axis CNC Machining

-

Precision Machined Copper Die Casting Parts

-

Professional Small Baler Aluminum Alloy Die-casting Mold Production

-

China Die Casting Factory Manufactures Surface Sprayed Aluminum Valve Body

-

Extrusion Die-casting Polyurethane-Coated Aluminum Alloy Profiles

-

Custom Precision Aluminum Die Cast Brackets and Finishes

-

Extrusion Die-casting Magnesium Alloy Heat Sink Shell