Large Metal Spinning

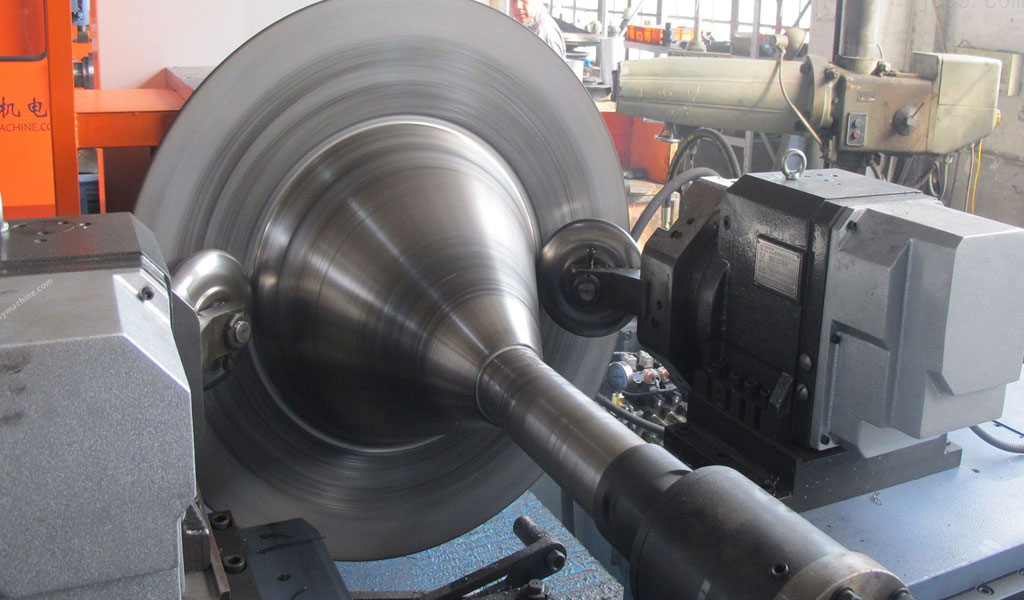

Spin forming is a machining process that uses tools like spinning wheels to apply pressure to a metal blank (a sheet or tube), which rotates along with the spindle of a lathe. This pressure induces continuous localized plastic deformation, shaping the metal into the desired hollow, rotationally symmetrical part without the need for extensive cutting.As the demand for aircraft, rockets, and missiles grew, the basic metal spinning process evolved into what is known as shear spinning, or power spinning. With the continual advancements in aircraft, missile, and spacecraft performance, spinning technology—especially power spinning—has become increasingly vital in the aerospace industry.

What Is Large Metal Spinning

Large metal spinning refers to create large-scale heavy gauge components, often with diameters exceeding several meters.This process is crucial for industries that require large, durable, and precisely engineered parts. Large metal spinning is distinguished by its ability to produce components with high structural integrity and precise dimensional accuracy.The ability to produce these components with high accuracy and efficiency has made large metal spinning a vital part of modern manufacturing, particularly in sectors such as aerospace, automotive, and architecture.

The primary differences between large and small-scale metal spinning lie in the equipment used, the techniques employed, and the scale of the operations. Large metal spinning often requires custom-built lathes capable of handling heavy workpieces, as well as advanced spinning tooling to manage the increased forces. The process also demands a higher level of expertise and precision to ensure the quality and consistency of the final product.

Large Metal Spinning Application

Large metal spinning is employed across a diverse range of industries, each requiring components that meet stringent specifications for strength, durability, and precision. In the aerospace industry, for instance, large metal spinning is used to manufacture rocket nose cones, satellite dishes, and other critical components. The automotive industry benefits from the process in producing large exhaust systems, structural parts, and even wheel rims. The energy sector relies on large metal spinning for components such as turbine housings, pressure vessels, and other parts essential to power generation.

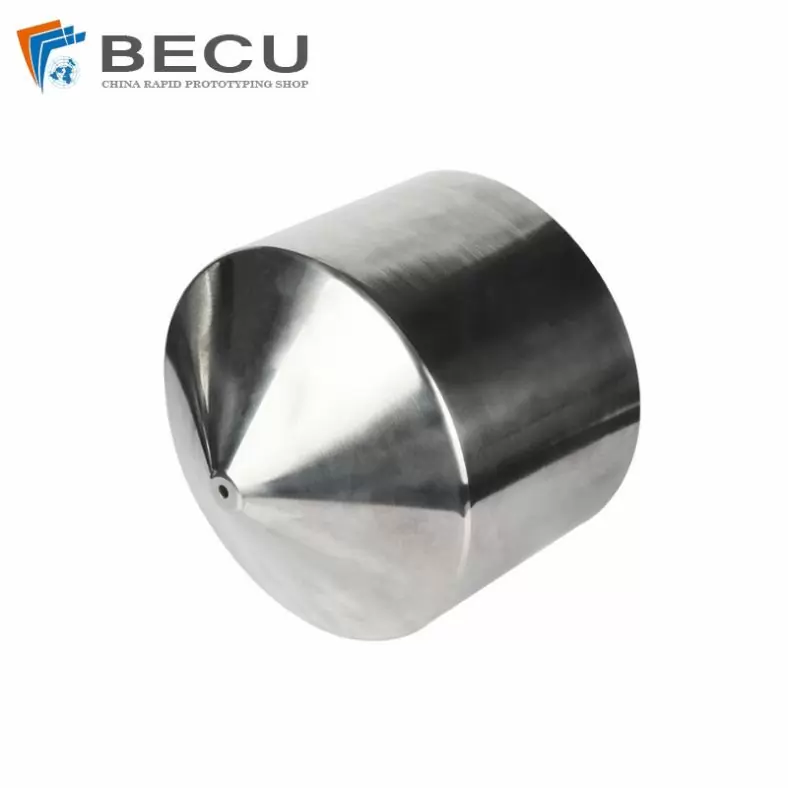

Power spinning is commonly used for manufacturing components such as missile bodies, end caps, tank heads, nose cones, nozzles, spherical or cylindrical pressure vessels, pipes, and various parts of aircraft engines, such as nozzles, combustion chamber cones, fairings, compressor disks, and turbine shafts.

Beyond aerospace, power spinning technology is also becoming increasingly prevalent in the fields of weaponry, naval vessels, and nuclear energy. It is used in the manufacturing of torpedo casings, periscope covers, shaped charge liners, tailpipes, rocket shells, gun barrels, and reactor components. Large-scale CNC power spinning machines are essential for the production of large, thin-walled, rotationally symmetrical metal structures in the aerospace sector. These machines are characterized by their high precision, heavy-duty rigidity, and high load capacity, catering to the manufacturing needs of large thin-walled rotating parts in industries such as aviation, aerospace, shipbuilding, nuclear power, and chemicals.

Large CNC Metal Spinning – Heavy Gauge Metal Spinning Manufacturer

Product Accuracy Is Our Attitude,Metal spinning services for spun parts and other applications.Where We Build Your Large Visions.At Be-cu.com, Large Metal spinning services for the cookware, marine, and HVAC industries,aerospace, energy, research and development, military, and defense industries.

In 2018, BE-CU Spinning Company completed the installation and commissioning of a 2600 vertical spinning machine, which is the largest CNC fully automatic vertical spinning machine in Asia. The successful deployment of this equipment marked a significant “dual breakthrough” in China’s spinning technology and equipment, signifying a new era in the production of large spinning machinery.

This large-scale spinning machine is capable of spin forming various materials, including stainless steel, Inconel®, titanium,copper,aluminum and alloys, brass and iron, with a maximum workpiece diameter of 2,600 mm. It was developed specifically for the production of large lighting fixtures.

Additionally, this machine can spin form tubular titanium workpieces and can automatically shape conical, R-shaped, and variously sized openings, including closed-end workpieces..CAD/CAM files are accepted.ISO Certified.We also have a strong supply chain that can scale with your project needs.Contact us to quote your large CNC spinning parts now.

Large Chimney and Cooker Spinning

Large Metal Venturi Spinning

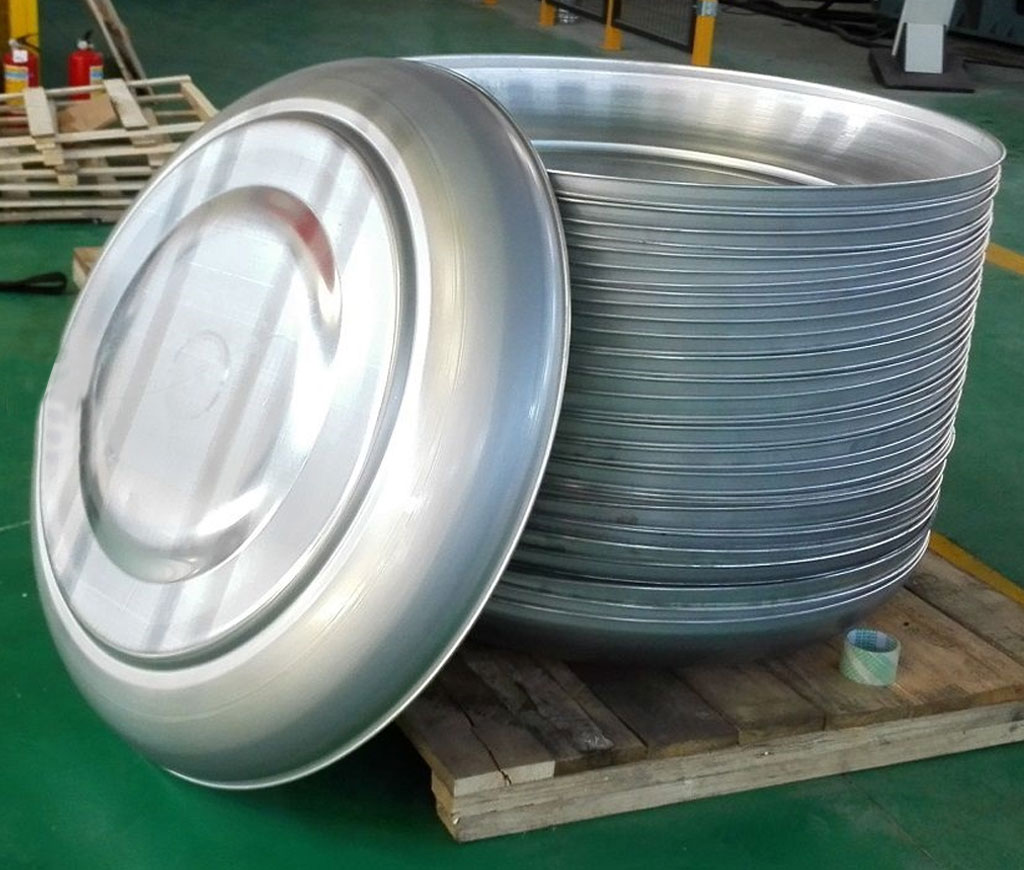

Metal Dish-Shaped Large Metal Spinning

Metal Hemispheres Large Metal Spinning

Metal Hemispheres Spinning Wireless signal transmitter

Metal Tank Heads Large Metal Spinning

Large Metal Spinning Capabilities

Parts produced using this technique boast high precision, excellent surface finish, uniform wall thickness, and minimal springback. Capable of close tolerance spinning from 0.5 to 60 in. diameter,spinning metal up to 2,600 mm dia. and 1,220 mm height.

- Spinning Depth: 600-650 mm or less

- Plate Thickness Range: Aluminum alloy plate 4 mm or less

- Steel Plate 0.6-3.5 mm or less

- Stainless Steel Plate 0.5-3.5 mm or less

- Copper Plate 0.6-3.5 mm or less

For small to medium-sized parts, the diameter and wall thickness tolerances can be controlled within a range of 0.03 to 0.05 mm, and the surface roughness (Ra) can be less than 0.8 μm. Moreover, since power spinning is a chipless process, it enhances material utilization and reduces costs.

Blanking Of Large Parts

Large Precision Riveting Welding

Large Box-Type Heating Annealing Furnace

Large Boring And Milling,Turning,Pliers

Welding and finishing work on large spun parts

Electrical Assembly

Our Case Studies Gallery Of Large Metal Spinning Parts

Custom Metal Spinning of large and heavy components. Works with ferrous, non-ferrous, exotic and powdered metals such as aluminum, stainless steel, titanium, gammalloy, Hastelloy®, Incoloy®, Inconel®, Monel®, Nitralloy®, Stellite® and waspaloy. Markets served include aerospace, defense, food processing, heavy equipment, medical equipment, oil, gas, power generation, transportation and general industrial.

-

Metal Spinning 45° Iron LED Light Shade

-

Aluminum CNC Spinning Ashtray Prototype

-

Precision Spinning 304 Stainless Steel LED Reflector

-

Custom LED Ceiling Chandelier Light Disc By CNC Spinning

-

Metal Spinning Lamp Iron Photography Lampshade

-

16 Inch Spinning Oxide High Bay Light Aluminum Reflector

-

Metal CNC Spinning Venturi Draught Fan Accessories

-

CNC Spinning 304 Stainless Steel Funnel

-

Precision CNC Spinning BBQ Grill Brass Ring Accessories

-

Aluminum Spinning Parts For Automobile Shock Absorbers

-

Metal Spinning 350mm High Voltage Electrode Shield

-

287mm Metal CNC Spinning Machinery Parts