Beauty Replacements Head

- No.: 440C Martensitic Stainless Steel

- Color: Custom

- Surface Treatment: Anodized Oxidation

- Product Material: Stainless Alloy

- Proofing Cycle: 7 days(100000 pcs/M)

- Application: Precision Cnc Machining

- machining Factory: Be-cu Rapid Prototyping Companies

- Product Category: Tooling CNC Machining

- Production Process: Cnc Turning

- Size: According To Customer’s Drawings

High-Quality Precision CNC Turning 440C Blade

440C is a type of stainless steel that is known for its high carbon content and excellent corrosion resistance. It is commonly used in applications where sharpness and durability are crucial, such as knife blades.

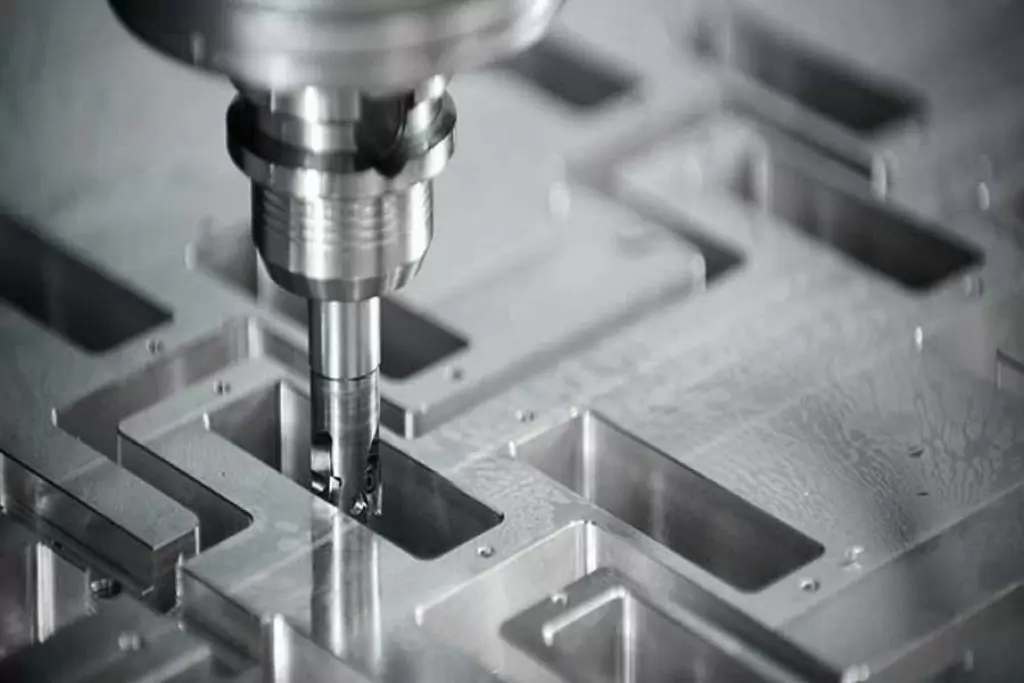

When manufacturing a precision CNC turned 440C blade, the process would involve designing a CAD (Computer-Aided Design) model of the blade, programming the CNC machine with the appropriate toolpaths and cutting parameters, and then allowing the CNC machine to cut and shape the 440C stainless steel according to the design specifications. The process would also involve quality control measures to ensure that the finished blade meets the desired dimensions and sharpness.

The precision CNC turning process allows for high accuracy, repeatability, and the ability to create complex shapes, making it ideal for producing high-quality blades for various cutting applications. It is essential to work with skilled machinists and quality materials to achieve the desired results when manufacturing a precision 440C blade.

Be-Cu Offering Precision CNC turning services for 440C Blade. Works with stainless steel and more metal. Other capabilities include milling and sawing. Production runs are available from 1 to 200,000 pieces.

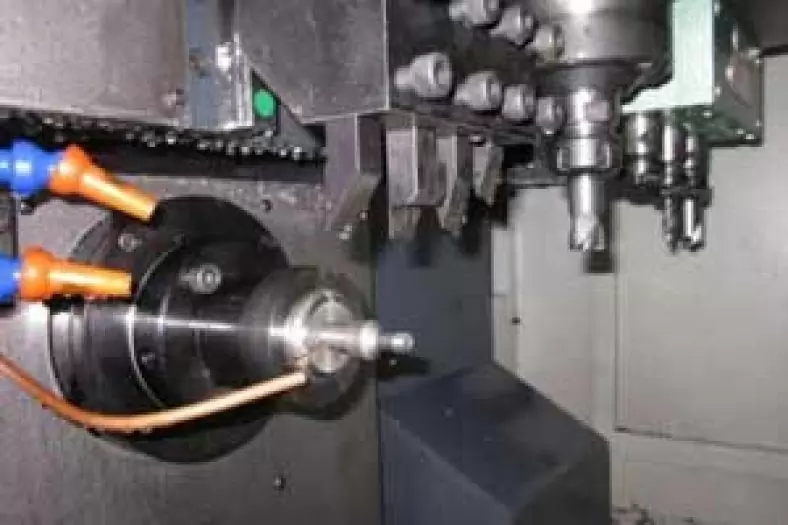

Our CNC turning process produces custom prototypes and end-use production parts in as fast as 1 day. We use a CNC lathe with live tooling so features like axial and radial holes, flats, grooves, and slots can be machined.

Why Choose Precision CNC Turning 440C Blade

Turning is different to CNC milling, in which the cutting tool rotates and is directed from multiple angles at the workpiece, which is usually stationary. The following are the advantages of CNC turning and grinding heads:

- Cylindrical parts:CNC turning machines are ideal for creating round or cylindrical parts. Lathes create these parts quickly, accurately and with excellent repeatability.

- Range of processes:Although generally used for parts of a certain shape, CNC turning can still be used to carry out a variety of cuts, including drilling, boring, threading and knurling.

- Advanced Equipment:Be-Cu has extensive in-house equipment for both manufacturing and testing. Your parts will be manufactured and inspected with our advanced in-house equipment.

Our engineers are always ready to work with you to ensure you get a quality product quickly. When you submit a 3D design file, we will negotiate with you to ensure the manufacturability of the design, resulting in a product that meets and exceeds your expectations. Contact us today for a free quote and design review.

The Advantages Of Precision CNC Turning 440C Blade

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Precision CNC Turning 440C Blade

| Material | Stainless Steel CNC Machining |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Cnc Turning,Milling, drilling, 5 axis cnc machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Machinery |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]