Laser Cutting For Stent

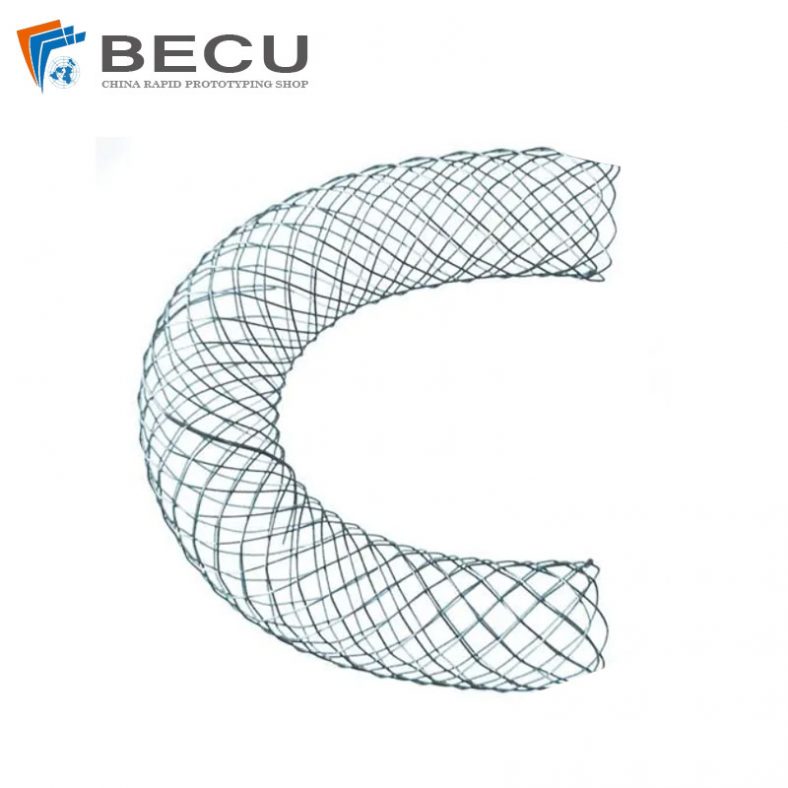

A medical stent is a small tube-like device typically made of metal or plastic that is used to open up and support a blocked or narrow passageway within the body. Stents are commonly used in various medical procedures to treat blockages in blood vessels, bile ducts, urinary tract, and other bodily structures.

The primary purpose of a stent is to help improve or restore the normal flow of fluids such as blood, urine, or bile through the affected area. For instance, coronary stents are used to open up narrowed arteries in the heart, while other types of stents might be used in the urinary system to alleviate blockages.

Stents can be designed in various shapes and sizes, depending on their intended use and the specific anatomy of the area they are meant to treat. Some stents are temporary and are eventually removed once the blockage or healing process is resolved, while others are designed to be left in place permanently.

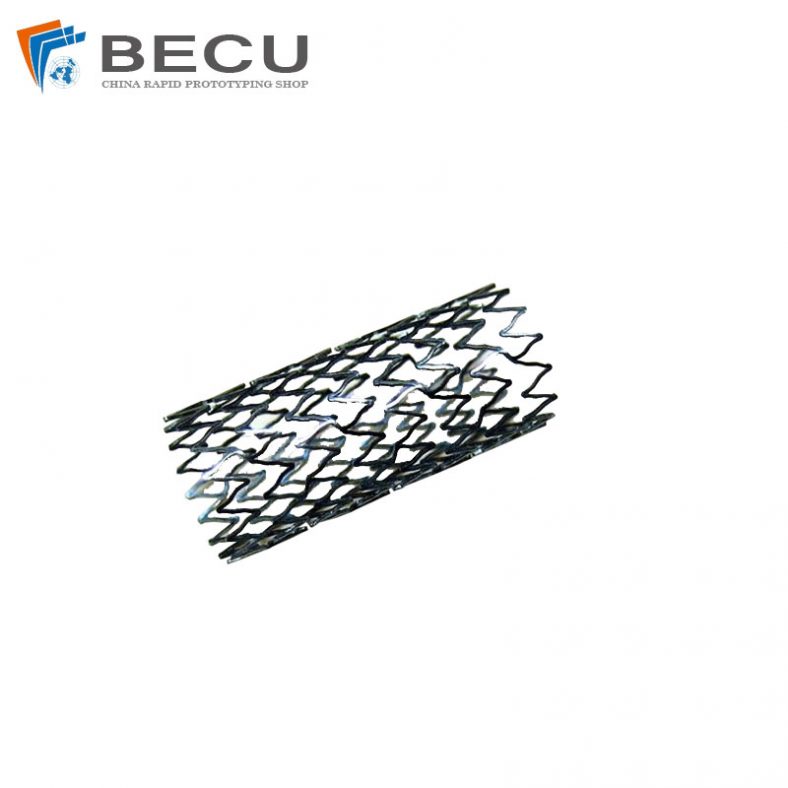

The insertion of a stent typically involves a minimally invasive procedure performed by a trained medical professional, such as a cardiologist, interventional radiologist, or urologist. Stents have been a significant advancement in modern medicine, providing a less invasive alternative to surgery in many cases and offering effective treatment for various conditions involving blocked or narrowed passageways within the body.Medical stent laser cutting is a specialized process used in the manufacturing of stents, which involves the precise use of laser technology to create the intricate patterns and shapes necessary for these devices. Laser cutting is a key technique in the production of stents due to its ability to achieve highly accurate and detailed cuts in various materials, such as metals like stainless steel or nitinol, as well as certain polymers used in stent construction.

Stent Laser Cutting Service – Precision Cutting For Medical Stent

If you need a highly skilled Laser Cutting company with plenty of relevant experience in the medical stent, Be-Cu prototype company is the place to turn. We are an experienced company that has the advanced equipment and talented staff needed to accurately create complex medical stent from a wide range of materials.

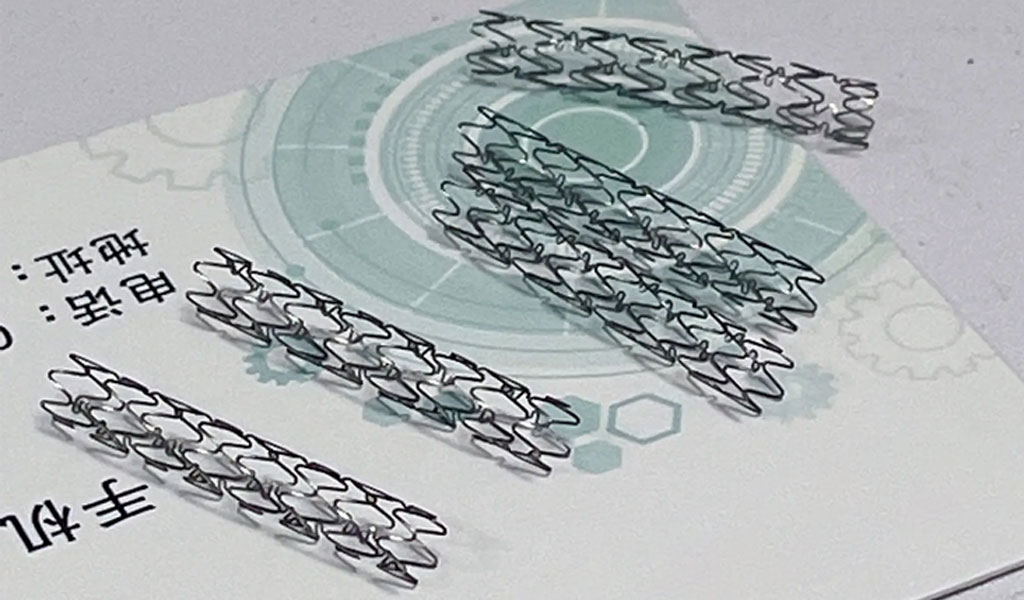

All of our medical laser cutting stent are delivered with tight tolerances and precise finishes. Precision and reliability are especially crucial when laser cutting medical stent and parts. When a laser cutting part is being used in a life-saving medical device, there is no room for error.

The precision laser cutter we use allow for 100% customization of production, rapid prototyping, and ultra-precise part production. Precision laser cutting machines also allow us to run jobs 24/7 which results in customers getting large orders quickly and efficiently.Be-Cu is an ISO 9001:2015 certified medical laser cutting shop, which means that our teams are required to maintain quality standards and make investments for continuous improvements.

Whether you need 10 custom parts, or 1,000,000, our precision machine shop can help maintain the quality and help you manage your supply chain efficiently. If precision and attention to detail are vital for the success of your medical industry project, we can deliver to your exact specifications.

Coronary Stent Laser Cutting

A coronary stent is a critical medical device used to treat coronary artery disease and ensure that a patient’s heart receives an adequate blood supply. These tiny and delicate devices require highly precise processing to ensure their performance and biocompatibility. Laser cutting technology is becoming increasingly important in the manufacturing process of coronary stents.

Challenges In Coronary Stent Cutting

Manufacturing coronary stents is a highly complex task as it must meet several key requirements:

- Precision: Coronary stents must be extremely precise to ensure they can accurately position and support the coronary arteries. Any slight manufacturing deviation can cause a medical device to fail.

- Biocompatibility: These stents will be implanted into the patient’s body and must have excellent biocompatibility to avoid rejection or other adverse effects.

- Surface quality: The smoothness and quality of the surface are critical to the performance of the stent, affecting not only blood flow but also the durability of the stent.

Advantages Of Laser Cutting In Coronary Stent Fabrication

In the manufacturing of coronary stents, laser cutting technology has shown great advantages. Here are some of its key benefits:

- High precision: Laser cutting can achieve micron-level precision, ensuring that the size and shape of the bracket fully meet the design requirements.

- No thermal effects: Laser cutting generally does not induce thermal effects, which means that the cut edges of the stent are not damaged by heat, helping to maintain biocompatibility.

- High efficiency: Laser cutting is a fast and efficient manufacturing method suitable for mass production and helps meet market demand.

- Suitable for a variety of materials: Laser cutting can be used for a variety of bracket materials such as stainless steel and cobalt-chromium alloy, and has strong versatility.

The Case Studies Of Stent Laser Cutting

You have a complex Stent design, Our Stent laser cutting service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.