Optical Instrument Parts

- No.: Aluminum 019

- Color: Custom

- Surface Treatment: Oxidation

- Product Material: Aluminum Alloy

- Proofing Cycle:7 days(100000 pcs/M)

- Application: Precision Cnc Machining

- machining Factory: Be-cu Rapid Prototyping Companies

- Product Category: Optical Instrument Parts

- Production Process: Cnc Machining

- Size: According To Customer’s Drawings

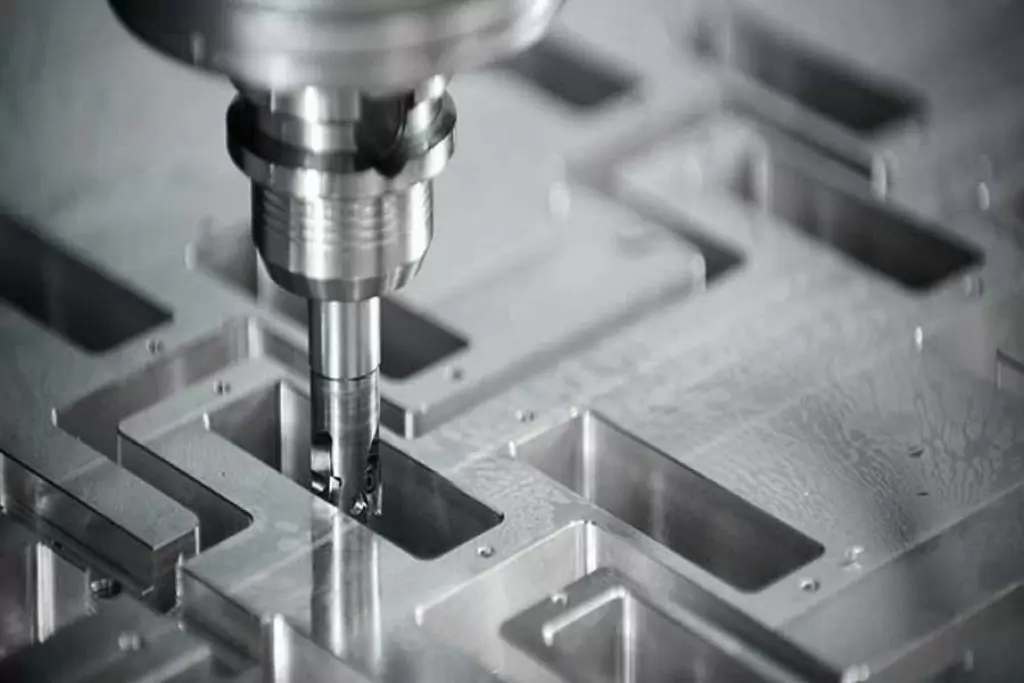

High-Quality Precision Lathe Processing Optical Instrument Mirror Body

Distributor of precision lathe optical instrument mirror body products. Products include abrasives, adapters, adhesives, attenuators, cables, cable systems, connectors, cutters, housings, probes, fiber optics and plastic films. Other products include dispensers and spray bottles, capillaries, caps, ultrasonic cleaners, laser diodes, processing fixtures, guides, interferometers, lathes, polishing pads and plates, scissors, protective sleeves, microscope slides, spools, dispensing syringes, Cable ties, crimping and cutting tools, glass, tubing, tweezers, piano wire and wavelength division multiplexers. Testing, consulting and fiber optic connector cross-section and analysis services are also available.

The Advantages Of Precision Lathe Processing Optical Instrument Mirror Bodys

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Precision Lathe Processing Optical Instrument Mirror Body

| Material | Aluminum Alloy 6061/6063 |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

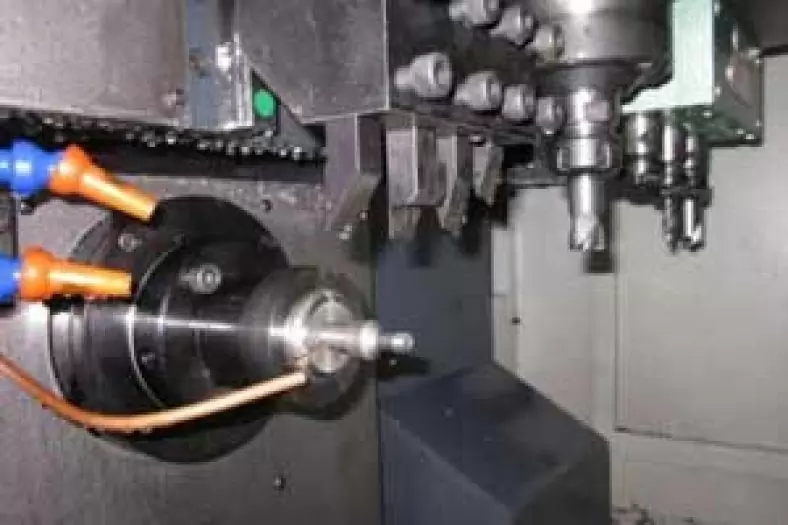

| Main Process | Milling, drilling, 5 axis cnc machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Optical industry |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]