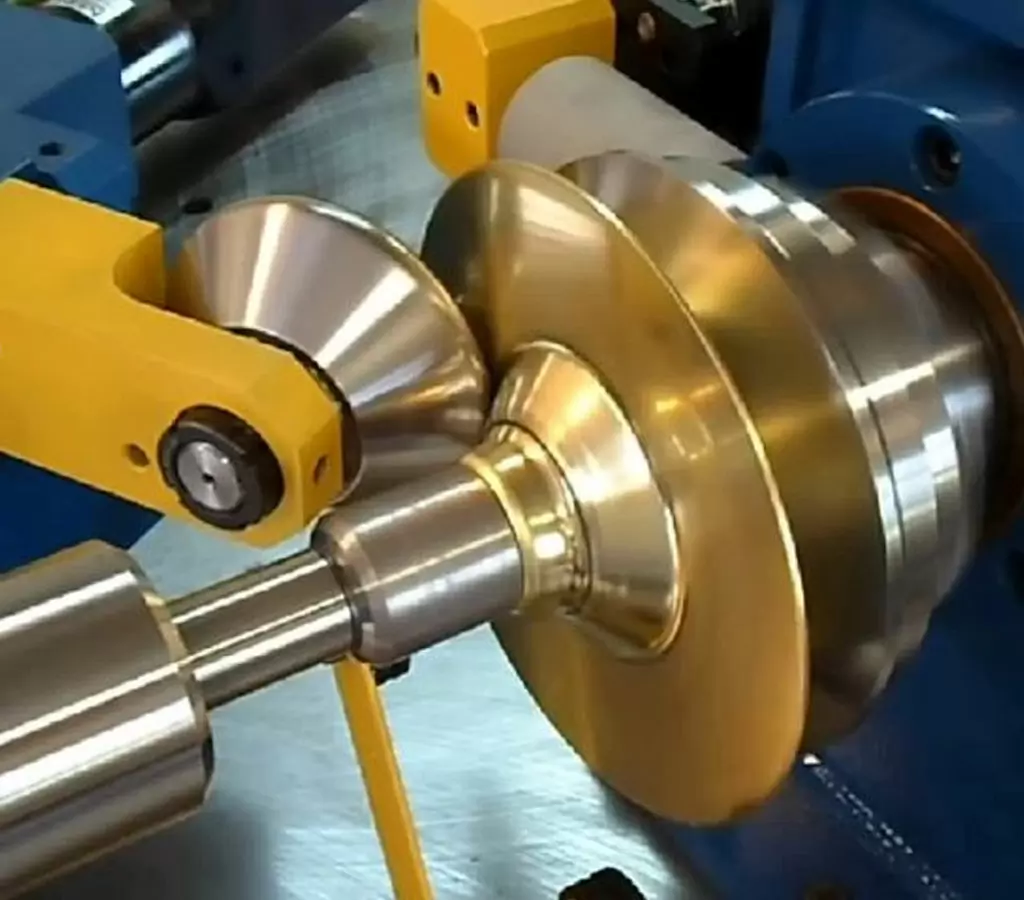

Brass Alloy In Metal Spun

Brass is essentially an alloy of copper and a small amount of zinc. It is strong, corrosion-resistant, and has excellent electrical conductivity. Due to its properties, brass spinning parts are suited for electrical applications.

Brass spinning is relatively strong and provides a high level of corrosion resistance. There are various techniques that you can utilize to fabricate brass spinning, such as cutting,cnc machining, forming, and welding. The varying content of zinc and copper in brass alloys makes them unique. Brass products are widely used in cooker accessories, decorative applications, and musical instruments.

Typical uses of brass spinning parts including kitchen utensils, Curved instrument mouth, handles, and other hardware. Whether you are looking into brass products with aesthetic appeal or mechanical brass parts, metal spinning is a way you can go.

Brass Alloys Used in Metal CNC Spinning

Generally, there are two common types of Brass alloys used in Metal CNC Spinning, they both contain more than 99% Brass and the remainder are impurities.

- Brass CDA 353 alloy is a leaded free-spinning alloy (FSA), ideal for parts that require strength, corrosion and wear resistance, and excellent machinability.

- Brass CDA 360 alloy has the highest Spunability of all copper alloys, extremely popular for parts that require strength, weight, or a polished surface finish. Available in round, square, hex, and tube stock at low costs, Brass 360 has a very wide range of applications, and is ideal for industrial and electronic industries. Unlike steel, 360 also forms a thin protective patina that does not rust.

Brass Spinning Services – Spun Brass Suppliers & Company

At Be-cu.com, our brass spinning services can supply custom brass parts with desired geometries and specifications. Fully-equipped facilities and seasoned technicians can get the job done efficiently and accurately. We’ll fabricate the cnc spinning brass parts based on the given designs using up-to-date machines and tools, which also improves productivity and quality. We provide precision brass fabrication and metal finishing services to achieve your manufacturing expectations. And we accept any projects as long as we can handle it, from the smallest brass sheet parts to the largest workpiece. Surface finishing processes can give your brass fabricated components a high-grade, attractive appearance and excellent characteristics that are perfect for your applications. Laser cutting, sawing, shearing, punching, cutting, bending, and more technologies are available here to take your drawings to the final product with competitive prices and the best service.

The Advantage Of Brass Spinning

Metal spinning offers a range of advantages to those looking for a very versatile, streamlined process, including:

- Lower Costs – Compared to the tools employed in alternative forming methods, Brass spinning tools are typically 10% of the cost.

- Shorter Lead Times – The Brass spinning process amounts to significantly shorter turnaround times – tools and spun components can be available within weeks rather than months.

- Maximum Design Flexibility – Brass spinning tools can be quickly and easily changed to accommodate evolving product designs, enabling flexibility when it’s needed most.

- Seamless, High-Quality Construction – Brass spinning produces smooth, durable objects without seams or welds, for parts require feature superior strength and great aesthetics.

Our Case Studies Gallery Of Spun Brass CNC Spinning

Put Be-cu.com’ experience to work for all of your Brass spinning and spin forming needs—from traditional manual Brass spinning to cutting edge CNC Brass spinning. The spun Brass spinning process is perfect for a wide variety of industries that require consistent tolerances, fast turn-around, and uncompromising quality.